Calcium sulfate retarder and preparation method thereof

A gypsum retarder and protein technology, which is applied in the field of gypsum building materials, can solve the problems of unsatisfactory loss of strength of gypsum products, and achieve the effects of easy acquisition, small strength loss and long setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a gypsum retarder, the mass percentage of raw materials is: 20% of animal keratin, 3.44% of sodium hydroxide, 7.5% of sodium dihydrogen phosphate, 3.75% of methyl acrylate, 0.01% of phenylethyl acetate , sodium benzoate 0.05% and diisopropylethylamine 0.2% and water 65%.

[0035] This embodiment also discloses the preparation method of this gypsum retarder. Add animal keratin and deionized water into a 500ml three-necked flask equipped with a stirrer and a thermometer, stir and heat up to 60°C, then add sodium hydroxide to adjust The pH value is 8.5, heat preservation and hydrolysis for 3 hours; then sequentially add sodium dihydrogen phosphate, methyl acrylate, sodium benzoate, diisopropylethylamine, and then add sodium hydroxide to adjust the pH value to 7, heat up to 90°C, and heat preservation reaction 3h; After the heat preservation is completed, add phenylethyl acetate, cool to below 40°C, and stir to obtain the gypsum retarder.

Embodiment 2

[0037] This embodiment discloses a gypsum retarder, the mass percentage of raw materials is: industrial gelatin 30%, potassium hydroxide 3.15%, sodium dihydrogen phosphate 7.5%, ethylenediaminetetraacetic acid 7.5%, phenylethyl acetate 0.05% %, sodium benzoate 0.1%, diisopropylethylamine 0.2% and water 51.5%.

[0038] This example also discloses the preparation method of this gypsum retarder. Add industrial gelatin and deionized water into a 500ml three-necked flask equipped with a stirrer and a thermometer, stir and heat up to 80°C, then add potassium hydroxide to adjust the pH The value is 8, heat preservation and hydrolysis for 4 hours; then sequentially add sodium dihydrogen phosphate, ethylenediaminetetraacetic acid, sodium benzoate, diisopropylethylamine, and potassium hydroxide to adjust the pH value to 10, and at the same time raise the temperature to 60°C, Insulate for 3 hours; add phenylethyl acetate after the end of the insulation, cool to below 40°C, and stir to ob...

Embodiment 3

[0040] This embodiment discloses a gypsum retarder, the mass percentage of raw materials is: 25% zein, 4% calcium hydroxide, 7.5% sodium dihydrogen phosphate, 7.5% maleic anhydride, 0.05% phenylethyl acetate, Sodium Benzoate 0.1% and Diisopropylethylamine 0.8% and Water 54.15%.

[0041] This example also discloses the preparation method of this gypsum retarder. Add zein and deionized water into a 500ml three-neck flask equipped with a stirrer and a thermometer, stir and heat up to 65°C, then add

[0042] Potassium hydroxide, adjust the pH value to 8.5, heat preservation and hydrolysis for 3 hours; then add sodium dihydrogen phosphate, maleic anhydride, sodium benzoate, diisopropylethylamine in turn, then add calcium hydroxide, adjust the pH value to 7, and raise the temperature at the same time Heat to 85°C and keep warm for 4.5 hours; after the keep warm, add phenylethyl acetate, cool to below 40°C and stir to get gypsum retarder.

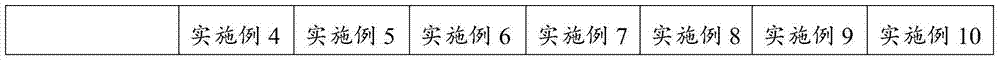

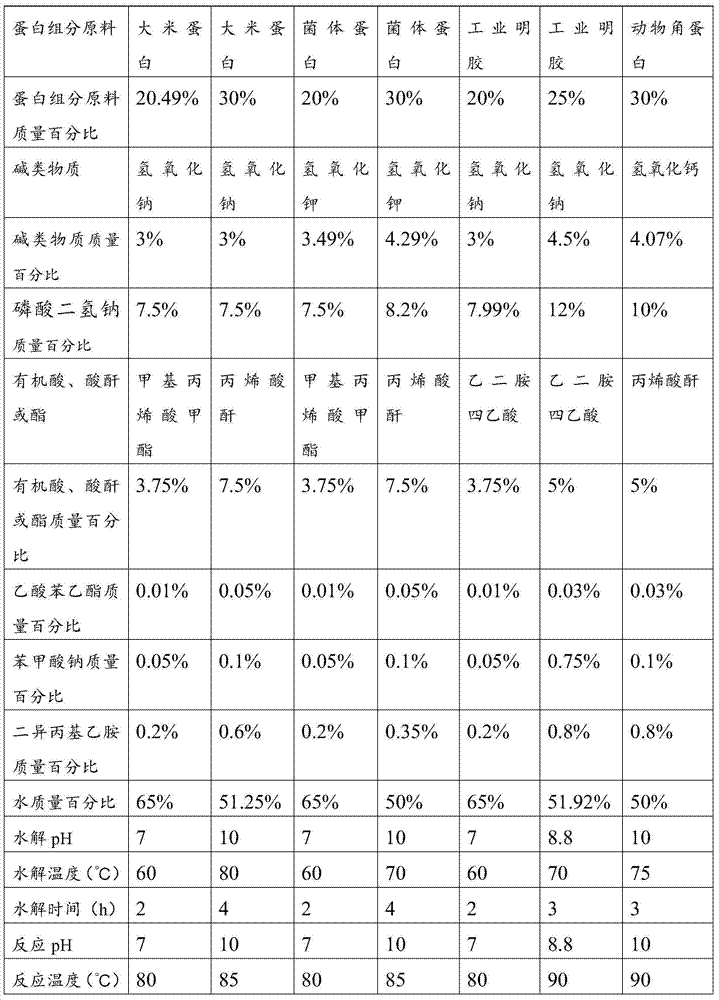

[0043] Embodiment 4-10 is shown in the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com