Production process of high-strength pre-stressed steel strands

A high-strength steel, production process technology, applied in metal material coating process, manufacturing tools, metal processing equipment and other directions, can solve the problems of low strength of production products, immature production process, large relaxation rate, etc., to achieve surface quality Good, high tensile strength, low relaxation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail:

[0029] Take the production of steel strands with a structure of 1×7, a diameter of 15.20mm, and a tensile strength of 2000MPa as an example:

[0030] (1) Raw material selection

[0031] Using diameter φ14mm, 82B wire rod high-carbon wire, the chemical composition of the wire rod is: C: 0.82-0.84%, S≤0.025%, P≤0.0255%, Si: 0.15-0.3%, Mn: 0.6-0.9%, Cr: 0.22-0.30%, V: 0.05-0.1%, wire rod tensile strength 1200-1250MPa, reduction of area> 30%;

[0032] (2) Wire rod surface treatment

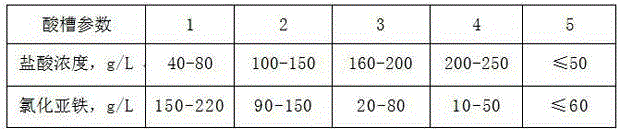

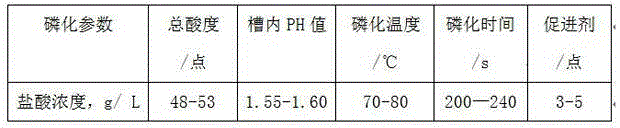

[0033] 1) The wire rod is pickled with hydrochloric acid, and the pickling time is 420s. At the same time, in order to reduce the corrosion of the acid solution on the steel base and improve the pickling effect, when the ambient temperature is 25°C, the addition ratio of corrosion inhibitor and hydrochloric acid is 0.012-0.015; hydrochloric acid Pickling adopts five pickling tanks for pickling, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com