High-grade duplex stainless steel with much suppressed formation of intermetallic phases and having an excellent corrosion resistance, embrittlement resistance castability and hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Method for Manufacturing and Testing Steel of Invention

[0099] A method for designing and manufacturing optimal alloys in accordance with the present invention will now be explained. The method for designing the alloy is obtained by optimally combining alloy design factors such as PREW of equation {circle over (1)}, [PREW(γ)−PREW(α)] for corrosion resistance balance of phases, Creq of equation {circle over (2)}, and Nieq of equation {circle over (3)}, and resultant values are shown in Table 2.

[0100] Creq and Nieq were calculated by the equation {circle over (2)} and {circle over (e)} to determine the composition, the alloying elements are melted in high frequency induction furnace using commercial pure grade of Fe, Cr, Mo, Ni, W, Cu, Si, Mn and Fe—Cr—N as recited in the claims of the invention, and deoxidized according to a common method such as Ti, Mg, Al, Ca or Al+Ca composite deoxidation, samples for casting melted in air, and samples for wrought products were melted in vacuum a...

example 2

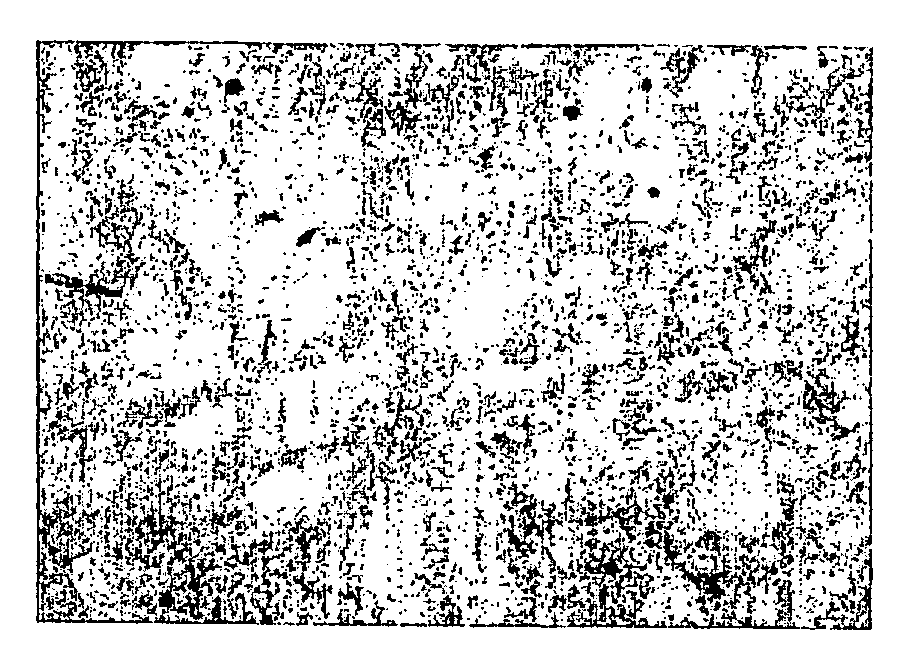

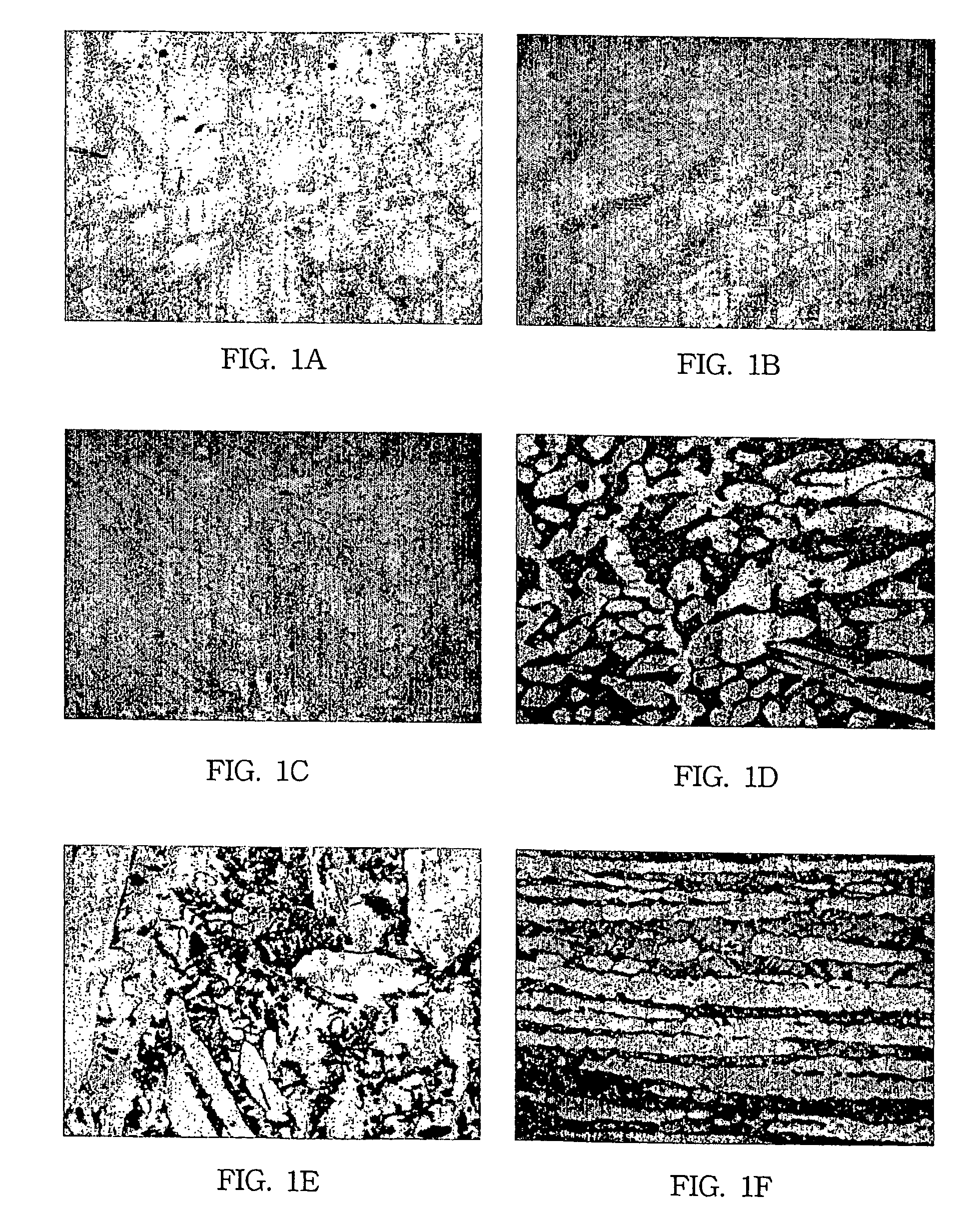

Comparison of Microstructures of Aged Products

[0110]FIGS. 1A to 1F are pictures of microstructures showing precipitation of brittle intermetallic phases deteriorating corrosion resistance and mechanical properties, such as sigma and khi of invention steel 4 (FIG. 1A), invention steel 10 (FIG. 1B) and invention steel 36 (FIG. 1C) aging heat-treated at 850° C. for 30 minutes, comparative steel 47 (FIG. 1D), and UR 52N+ (FIG. 1E) and SAF 2507 (FIG. 1F) which are commercial high-grade duplex stainless steels. Bright parts show austenitic phase, and dark parts show ferritic phase decomposed into sigma phase+austenite phase in the aging heat-treatment. The degree of precipitation of the intermetallic phases was ‘invention steel 4=invention steel 10=invention steel 3647’. As a result, invention steels 4, 10 and 36 suppressed precipitation of the intermetallic phases more than commercial steels UR 52+ and SAF 2507 and comparative steel 47, to remarkably improve embrittlement resistance.

example 3

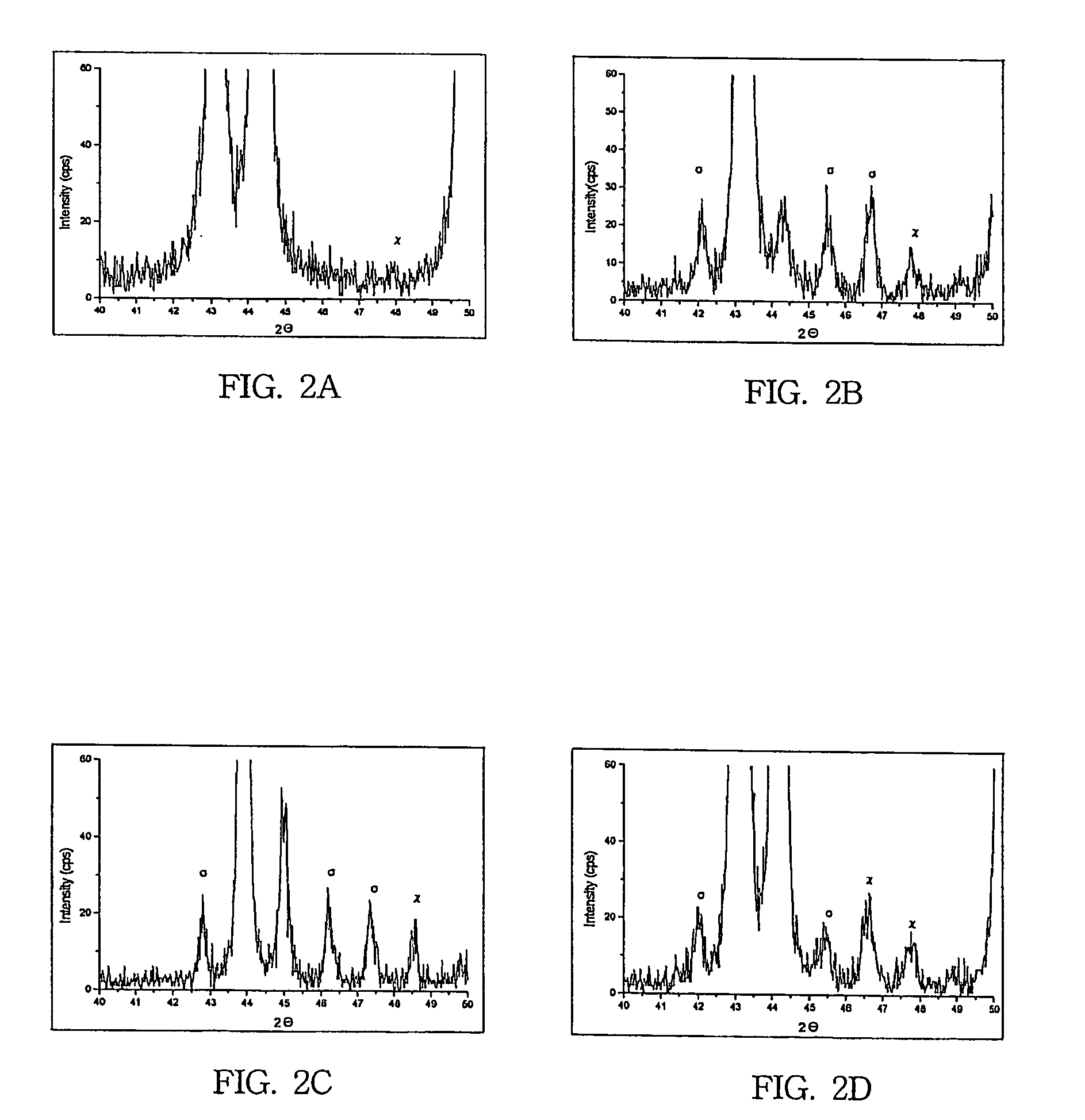

X-ray Diffraction Analysis Test

[0111]FIGS. 2A to 2D are graphs of X-ray diffraction analysis test results showing precipitation of brittle intermetallic phases deteriorating corrosion resistance and mechanical properties, such as sigma and khi of invention steel 4 (FIG. 2A) aging heat-treated at 850° C. for 30 minutes, comparative steel 47 (FIG. 2B), and UR 52N+ (FIG. 2C) and SAF 2507 (FIG. 2D) which are commercial high-grade duplex stainless steels. As compared with comparative steel 47 and commercial steels UR 52+ and SAF 2507, invention steel 4 did not precipitate sigma phase, and precipitated little khi phase, to considerably improve embrittlement resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com