Quantitative analyzing method for non-metal residue in steel

A non-metallic inclusions, quantitative analysis technology, applied in the direction of material analysis, image analysis, material analysis through optical means, etc., can solve the problems of low work efficiency, high labor intensity, observation error, etc., to improve accuracy and efficiency, Realize the effect of mutual conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The present invention has taken following technical contents:

[0029] 1. Use image stitching and multi-field (more than 60) statistical techniques;

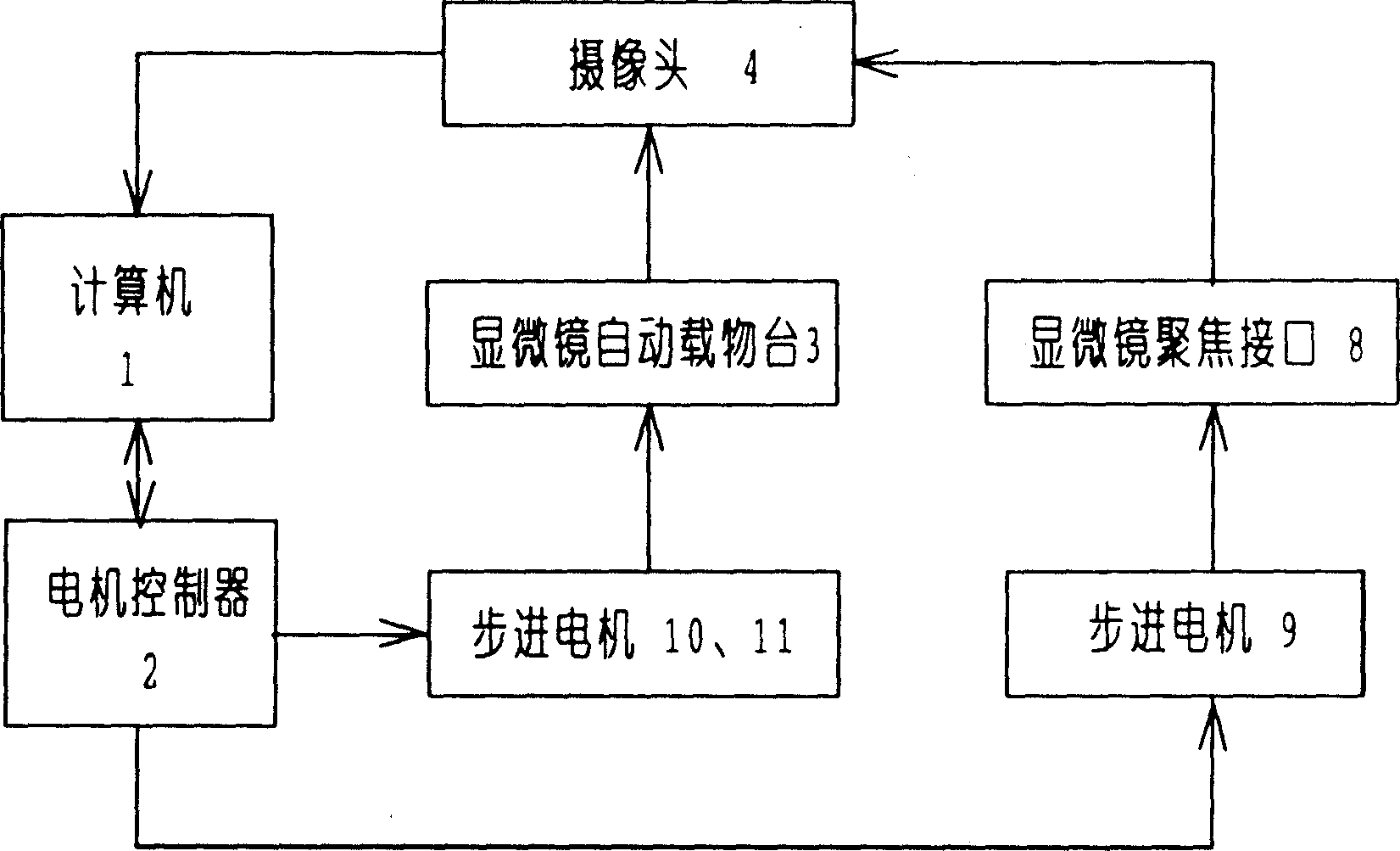

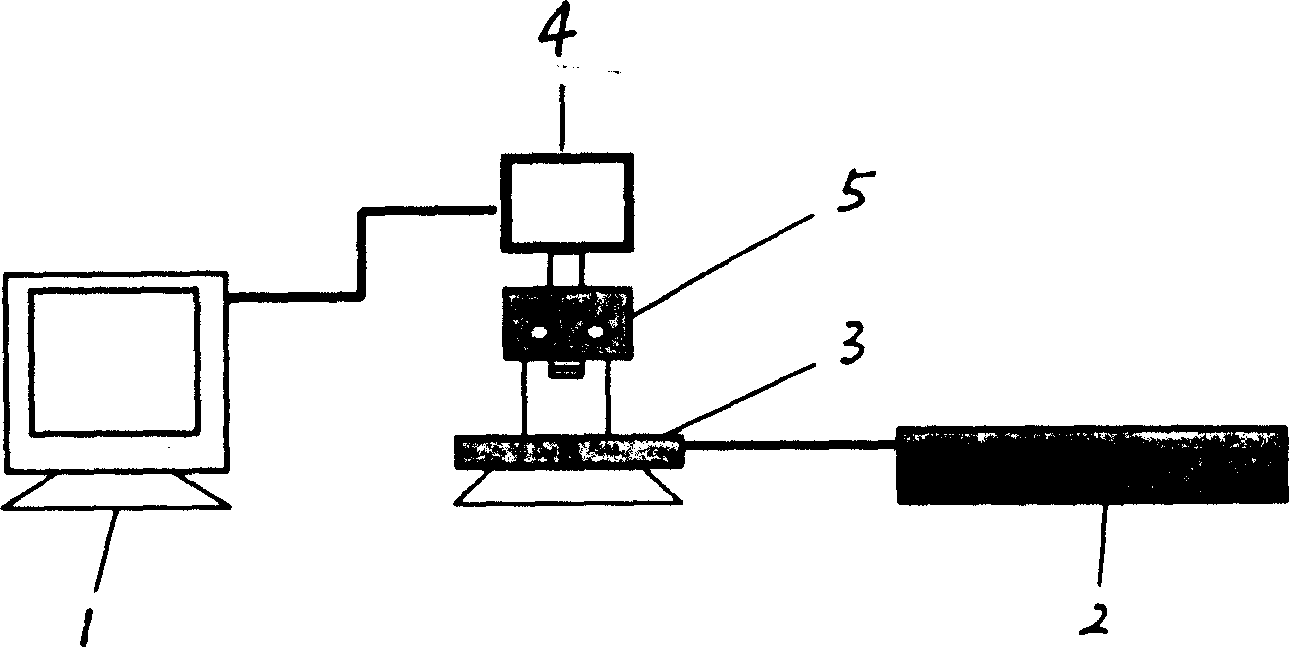

[0030] 2. In order to ensure continuous image acquisition, an automatic stage is used, and the automatic stage is controlled by software to move;

[0031] 3. The quantitative results of inclusion content with different definitions are directly given in the software, and rich statistical data of inclusion parameters are provided at the same time;

[0032] 4. The software includes multi-national inclusion evaluation standards, and the evaluation results of national standards can be converted to each other.

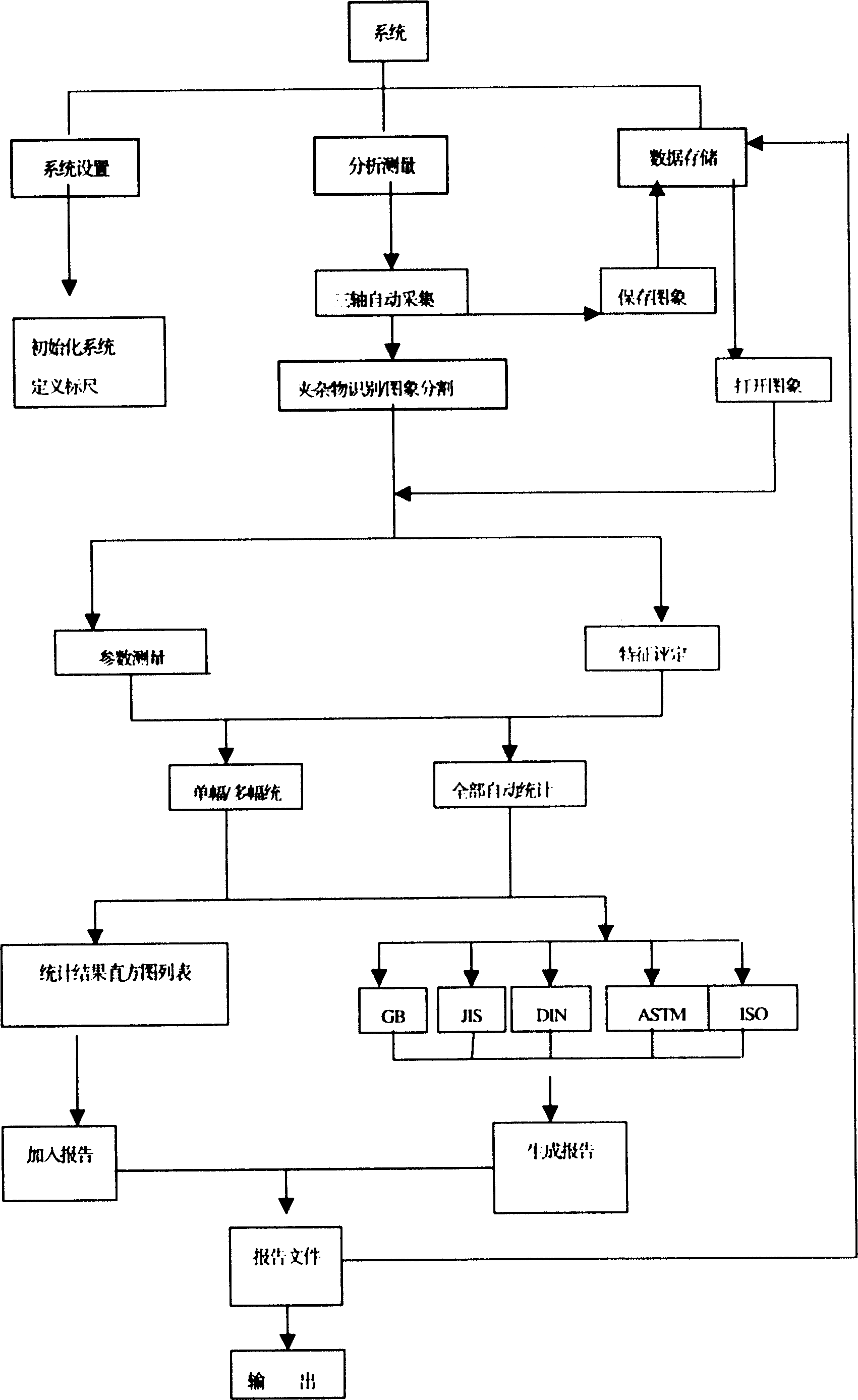

[0033] The quantitative analysis steps adopted in the present invention are divided into: initial setting and calibration of the system, automatic scanning, image acquisition, inclusion extraction, image analysis, report generation and file storage, which will be described separately below.

[0034] The system perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com