Method for preparing aluminum-magnesium-aluminum three-layer metal composite plate by prefabricating crossed corrugated interface

A technology of metal composite board and cross corrugation, which is applied in metal rolling and other directions, can solve the problems of serious texture on the base surface of magnesium board and low bonding strength of composite board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] S1. Material selection: select an AZ31B magnesium plate with a size of 100mm×30mm×3mm as the substrate, and perform heat preservation treatment before rolling in a vacuum heating furnace, with the temperature set at 400°C and the time set at 30min.

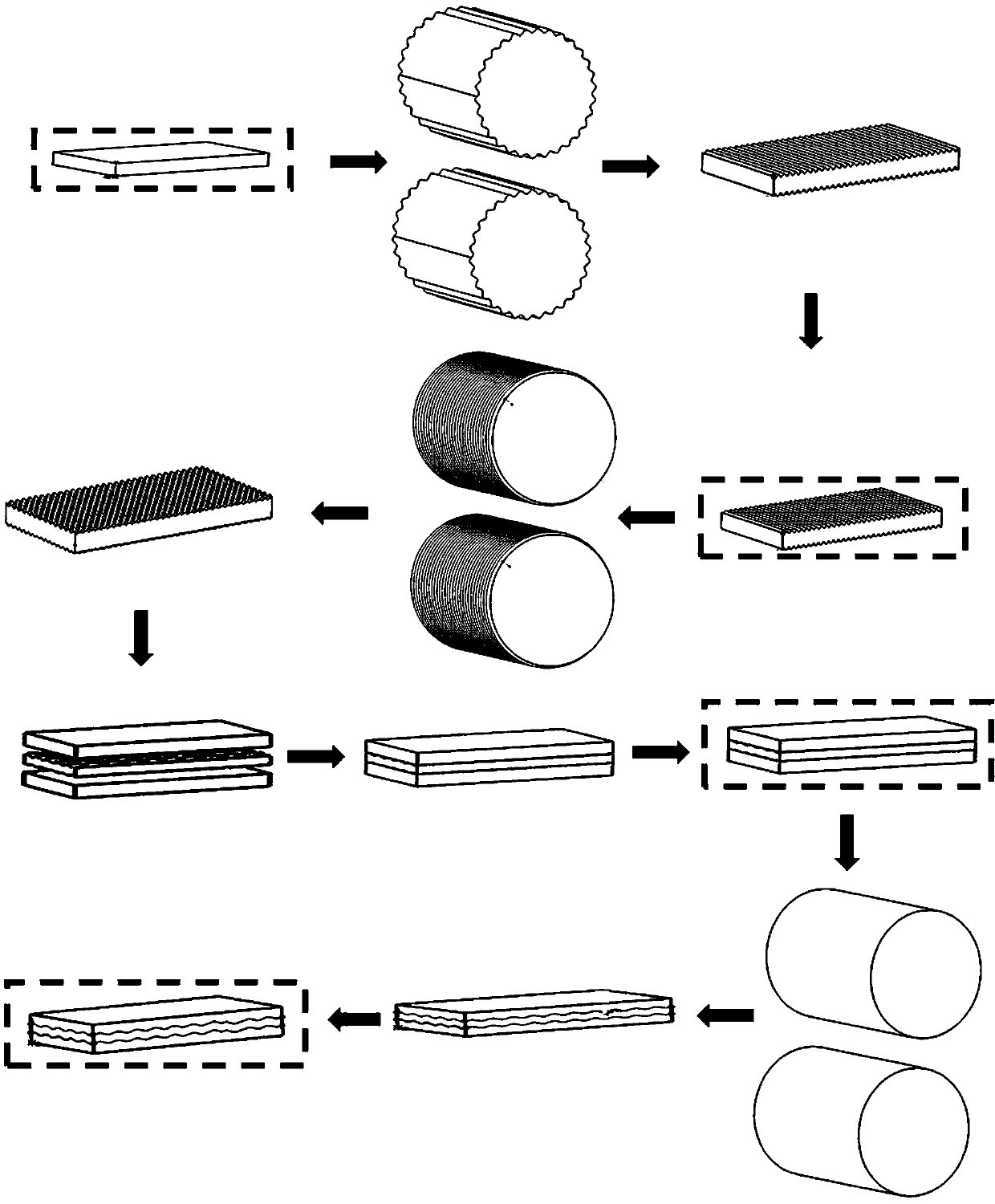

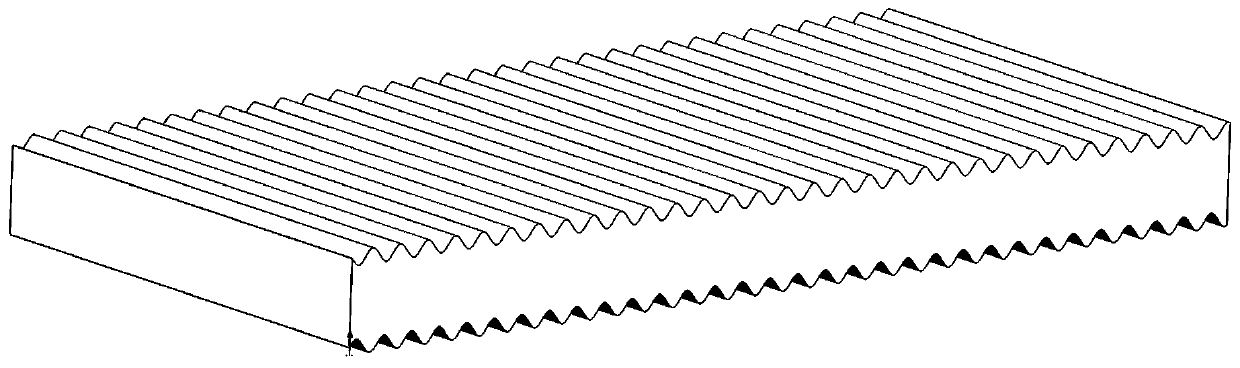

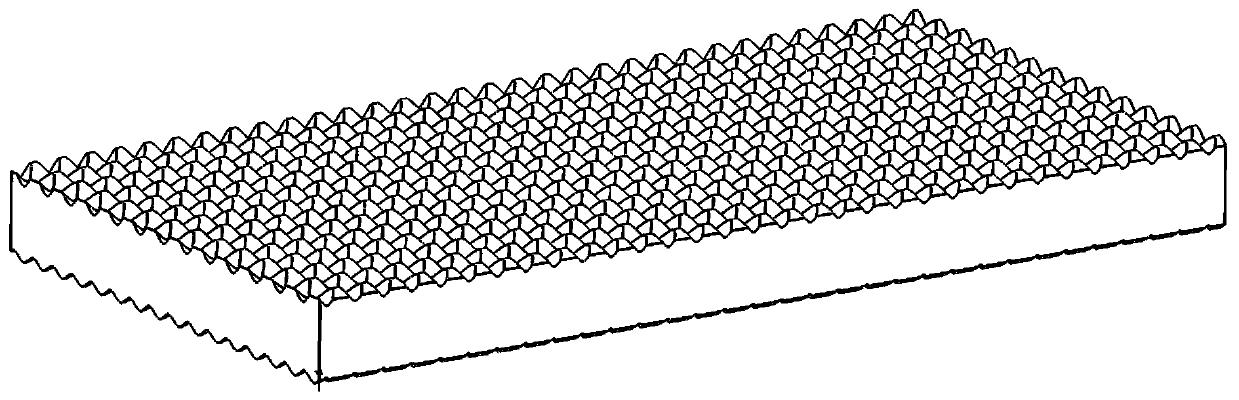

[0048] S2, the first pass of rough rolling: put the above-mentioned magnesium plate that has been heat-preserved before rolling into the two-roll rolling mill a in which the upper and lower rolls are corrugated rolls, and the magnesium plate is rolled in the first pass to obtain Corrugated magnesium plates with unidirectional corrugations on the upper and lower surfaces, such as figure 2 shown.

[0049] S3. Intermediate heat preservation treatment: The corrugated magnesium board obtained above with unidirectional corrugations on the upper and lower surfaces is subjected to intermediate heat preservation treatment in a vacuum heating furnace. The heat treatment system is consistent with the steps, the temperature is set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com