Method for preparing laminar alpha-Al2O3 pearlescent pigment base material by use of compound aluminum salt

A flaky, aluminum salt technology, applied in the field of materials, can solve the problems of small particle size of flaky alumina, small particle size, and increased raw material cost, so as to reduce transformation and growth temperature, reduce raw material cost, and facilitate crystal seeds Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

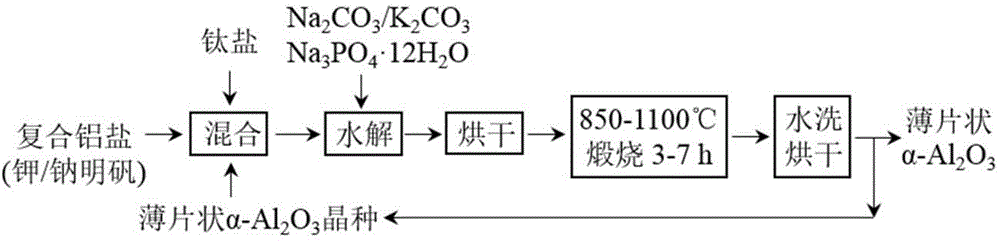

Method used

Image

Examples

Embodiment 1

[0049] 1) 46.5g KAl(SO 4 ) 2 12H 2 O was dissolved in 150mL deionized water to obtain KAl(SO 4 ) 2 12H 2 O saturated aqueous solution, then add 0.11g TiOSO 4 (purity 93%) or 3.7gTiCl 4 The aqueous solution (mass percentage concentration is 3.2%), after it dissolves, fully stirs 30min, obtains suspension a;

[0050] 2) 15.6g anhydrous Na 2 CO 3 and 0.27g Na 3 PO 4 12H 2 O was dissolved in 150mL deionized water to prepare solution b;

[0051] 3) Add solution b to suspension a and fully stir at room temperature to carry out hydrolysis reaction. The reaction time is 1 hour. After the reaction is completed, a gel mixture is obtained. Evaporate and dry the above-mentioned gel mixture, grind the dried gel into powder and pass through a 100-mesh standard sieve (2 o 3 .

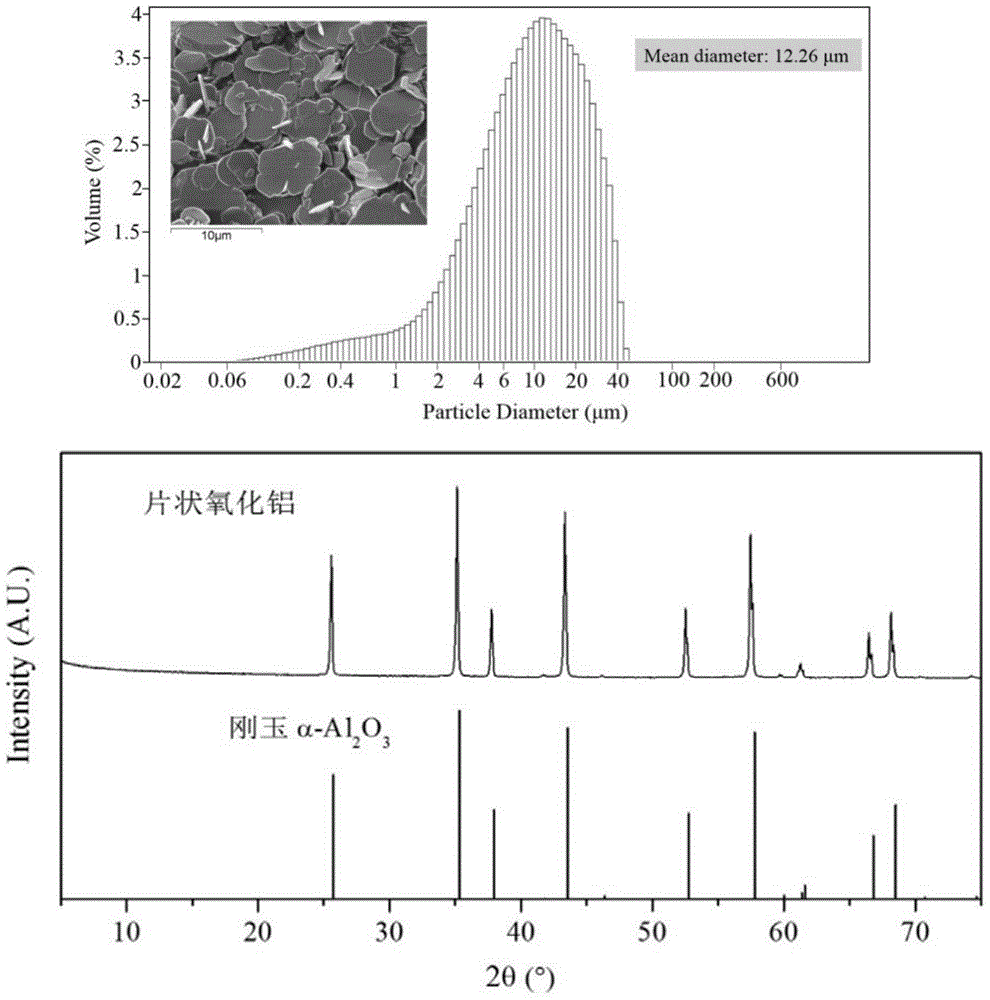

[0052] The flaky α-Al 2 o 3 The thickness is 0.2μm-0.5μm, the average particle size is 11μm and the distribution is uniform, the aspect ratio is greater than 20, and there is no twinning and agglomerat...

Embodiment 2

[0054] 1) 46.5g KAl(SO 4 ) 2 12H 2 O was dissolved in 150mL deionized water to obtain KAl(SO 4 ) 2 12H 2 Saturated aqueous solution of O, add 0.11g TiOSO 4 (purity 93%) or 3.7gTiCl 4 aqueous solution (mass percentage concentration is 3.2%), after it dissolves, add 0.25g flake α-Al 2 o 3 As a seed crystal, stir thoroughly for 30 minutes to obtain a suspension a; the flaky α-Al used as a seed crystal in this step 2 o 3 Seed crystal is the product obtained in Example 1;

[0055] 2) 15.6g anhydrous Na 2 CO 3 and 0.13g Na 3 PO 4 12H 2 O was dissolved in 150mL deionized water to prepare solution b;

[0056] 3) Add solution b to suspension a and fully stir at room temperature to carry out hydrolysis reaction. The reaction time is 1 hour. After the reaction is completed, a gel mixture is obtained. Evaporate and dry the above gel mixture, grind the dried gel into powder and pass through a 100-mesh standard sieve (2 o 3 .

[0057] The flaky α-Al 2 o 3 The X-ray diffr...

Embodiment 3-8

[0060] The method of Examples 3-8 is similar to that of Example 2, except that the amount of additives is different, and the detailed conditions are as described in Table 1. The obtained flaky α-Al 2 o 3 The characteristics are shown in Table 2.

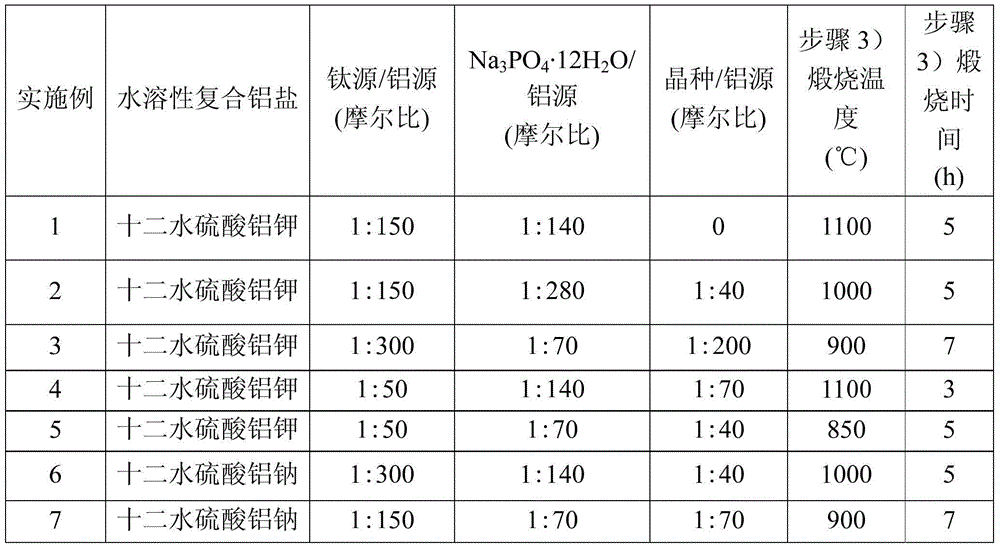

[0061] Table 1, embodiment 1-8 experimental conditions

[0062]

[0063]

[0064] In table 1, the molar ratio of titanium source / aluminum source (molar ratio) that is crystal growth regulator and water-soluble composite aluminum salt;

[0065] Na 3 PO 4 12H 2 O / Al source (molar ratio) also Na 3 PO 4 12H 2 O and step 1) in the mol ratio of water-soluble composite aluminum salt;

[0066] Seed crystal / aluminum source (molar ratio) that is, flake α-Al 2 o 3 The mol ratio of crystal seed and described water-soluble composite aluminum salt;

[0067] Table 2, the obtained flaky alumina characteristics of Examples 1-8

[0068] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com