Method for refining magnesium alloy crystal grains

A technology of grain refinement and magnesium alloy, which is applied in the preparation of magnesium alloy grain refinement through the "preset twinning-low temperature thermal deformation" method, and in the field of magnesium alloy grain refinement, can solve the problem of expensive forming molds and low process Complicated, will introduce problems such as impurities or defects, to achieve the effect of small grain size, simple production equipment, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

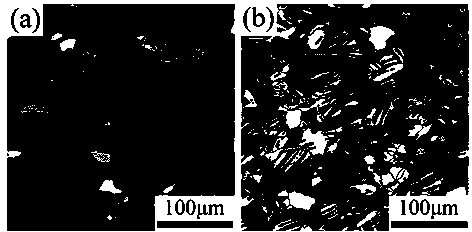

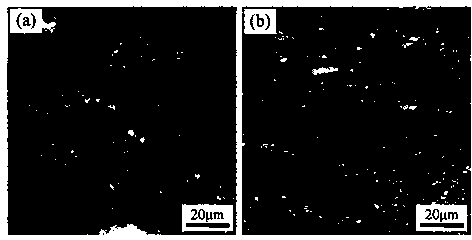

[0020] Twins were pre-set in AZ31 magnesium alloy slabs by pre-rolling at room temperature with a pre-rolling deformation of 5%, followed by annealing at 200 °C for 6 h. attached figure 1 It is the EBSD diagram of the original magnesium alloy sheet and the pre-rolled and annealed pre-twinned sheet. It can be seen that a large number of twins have formed in the pre-rolled magnesium alloy sheet, and the twinned structure is still intact after low-temperature annealing for 6 hours. It is judged by EBSD that these twins are mainly {10-12} tensile twins, and the twin layers in each grain are almost parallel, and the content of tensile twins is 59%. Then, the original sheet and the pre-twinned sheet were compressed and deformed at 200 °C with a compression deformation of 65% and a strain rate of 10 -3 the s -1 . attached figure 2 It is the EBSD diagram of the original sheet and the pre-twinned sheet subjected to 65% compression deformation at 200°C. It can be seen that after th...

Embodiment 2

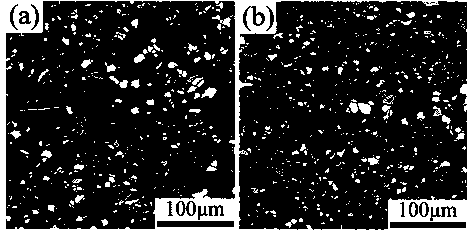

[0022] Twins were pre-compressed in AZ31 magnesium alloy slabs at room temperature with a pre-compression deformation of 6%, followed by annealing at 180 °C for 8 h. Then the original sheet and the pre-twinned sheet were rolled and deformed at 200 °C with a compression deformation of 25% and a strain rate of 10 -1 the s -1 . attached image 3 It is the EBSD diagram of the original sheet and the pre-twinned sheet after 25% rolling deformation at 200°C. It can be seen that after hot rolling deformation, the structure of the original sheet is not uniform, and the coarse grains and fine dynamic recrystallization grains alternate distribution, and the dynamic recrystallization induced by the preset twins obviously refines the grain structure of the magnesium alloy, and the structure is uniform and fine. Compared with the original sheet, the grain size of the preset twinned sheet after hot rolling can be refined to 4.1 μm.

Embodiment 3

[0024] AZ31 magnesium alloy slabs were pre-twinned by pre-rolling at room temperature with a pre-rolling deformation of 8%, followed by annealing at 200 °C for 10 h. Then, the original sheet and the pre-twinned sheet were subjected to extrusion deformation at 200 °C, with an extrusion deformation of 80% and a strain rate of 10 -3 the s -1 . After hot extrusion deformation, the structure of the original plate is not uniform, and the coarse grains and fine dynamic recrystallization grains are distributed alternately, while the dynamic recrystallization induced by the preset twins obviously refines the grain structure of the magnesium alloy, and the structure is uniform Small, compared with the original sheet, the grain size of the pre-twinned sheet after hot extrusion can be refined to 2.8 μm.

[0025] The invention pre-deforms twins in the magnesium alloy, then performs low-temperature annealing to eliminate the influence of dislocations and retains the twin structure, and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com