Polymer matrix composite membrane with high energy density and preparation method thereof

A technology of polymer and composite membrane, applied in the direction of inorganic raw material rayon, textile and papermaking, fiber processing, etc. problems, to achieve the optimization of dielectric properties and energy storage properties, improve compatibility, and reduce defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

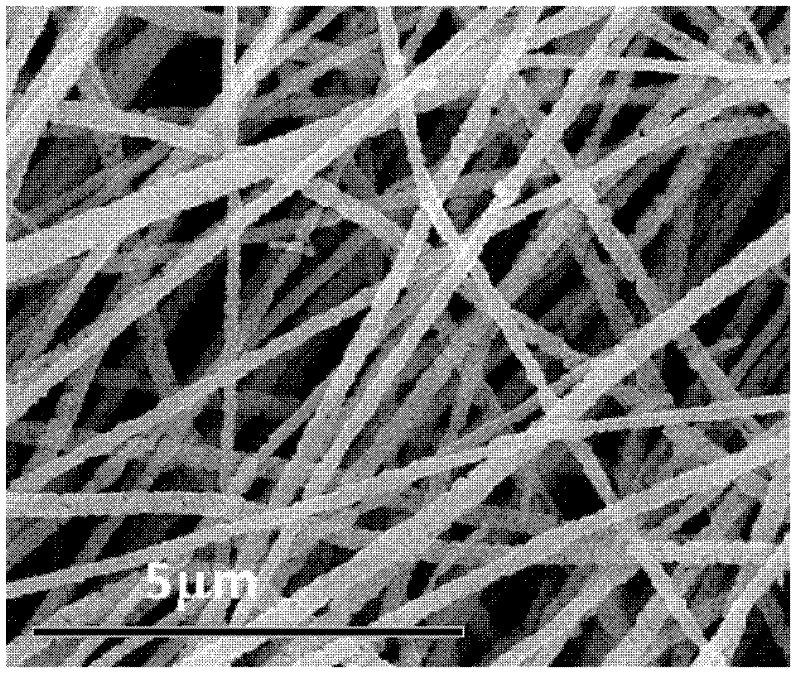

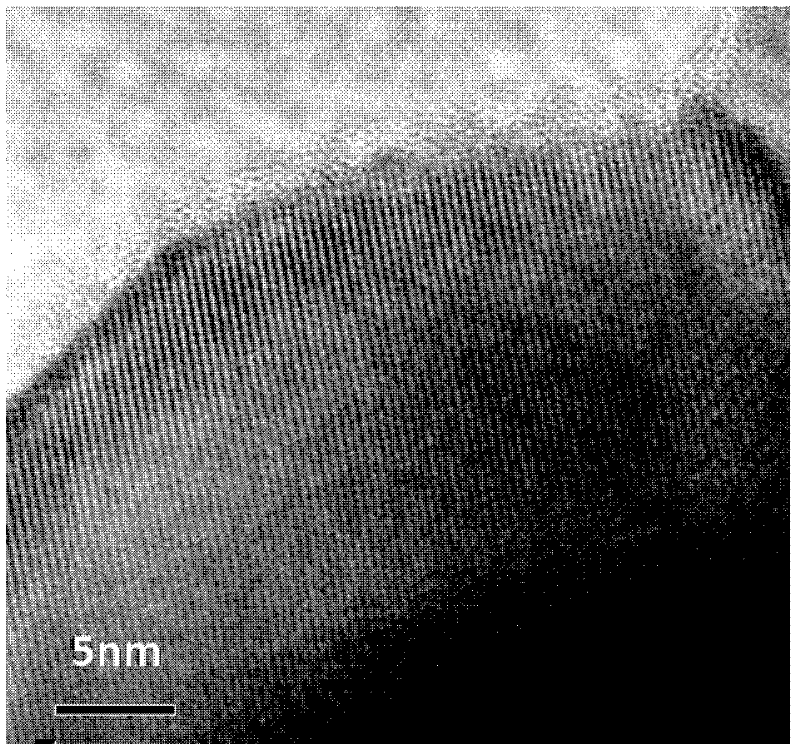

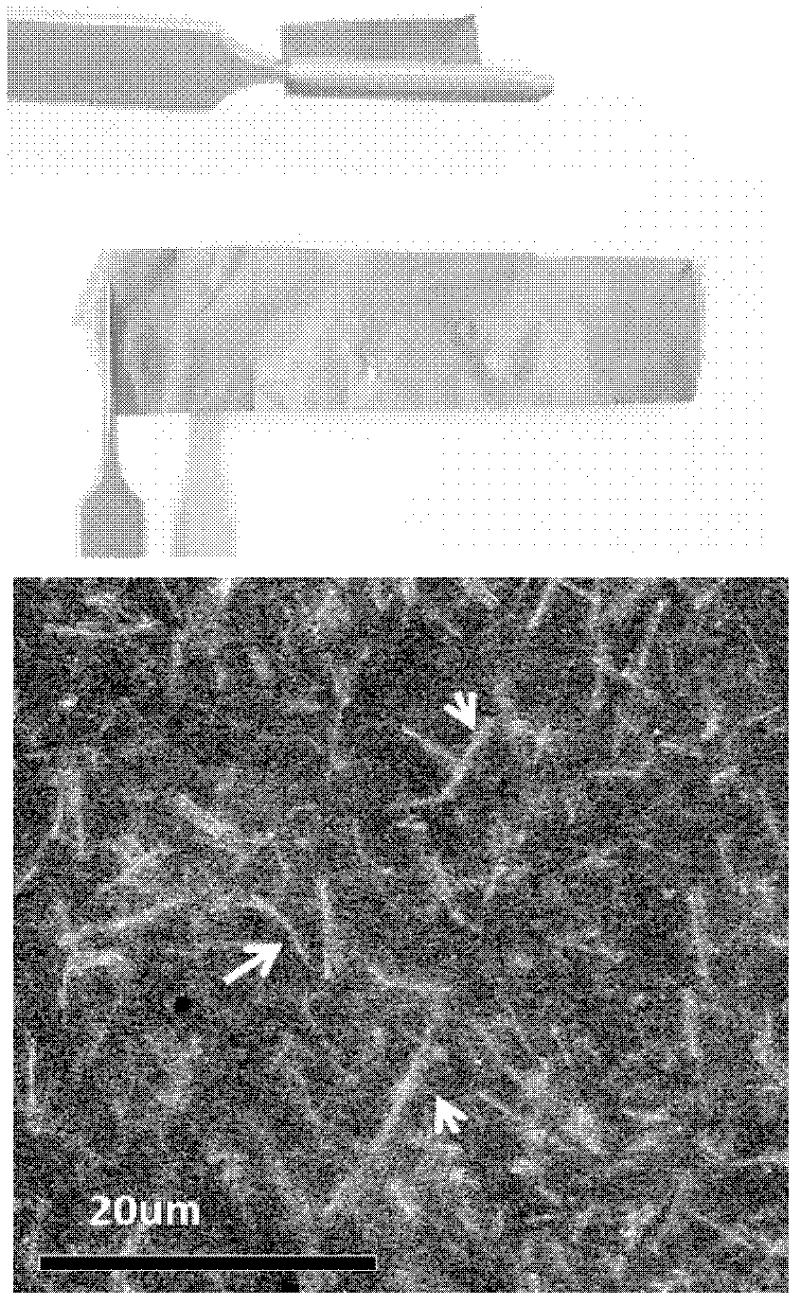

[0032] Embodiment 1, preparation PVDF base flexible composite film

[0033] Weigh 2.54g of barium acetate, 1.73g of tetrabutyl titanate, and 1.4g of acetylacetone into 10ml of acetic acid in sequence and stir evenly, then add 0.4g of PVP (molecular weight: 1.3 million) and stir for 3 hours to form a stable sol. Electrospinning, the voltage is 15kV, the distance between the receiver and the needle is 10cm. The collected fibers were calcined at 950 °C for 6 h to obtain BaTiO 3 Nanofibers. Take 0.4g BaTiO 3 The nanofibers were placed in 40 mL of 0.01 mol / L dopamine aqueous solution, stirred in a water bath at 60° C. for 10 h, centrifuged, washed with ethanol, and dried to obtain BNFDopa nanofibers. Add 10mL of DMF solvent to the obtained BNFDopa nanofibers, sonicate for 1h, then add 0.6g PVDF (molecular weight 4-100,000), stir for 4h until uniformly mixed, pour the mixture into a casting machine to form a film, and dry at 50°C for 3h. A flexible composite film is obtained.

[...

Embodiment 2

[0037] Embodiment 2, preparation PVDF base flexible composite film

[0038] Weigh 2.54g of barium acetate, 1.73g of tetrabutyl titanate, and 1.4g of acetylacetone into 10ml of acetic acid in sequence and stir evenly, then add 0.4g of PVP (molecular weight: 1.3 million) and stir for 3 hours to form a stable sol. Electrospinning, the voltage is 15kV, the distance between the receiver and the needle is 10cm. The collected fibers were calcined at 950 °C for 6 h to obtain BaTiO 3 Nanofibers. Take 0.2g BaTiO 3 The nanofibers were placed in 20 mL of 0.01 mol / L dopamine aqueous solution, stirred in a water bath at 60° C. for 10 h, centrifuged, washed with ethanol, and dried to obtain BNFDopa nanofibers. Add 10mL of DMF solvent to the obtained BNFDopa nanofibers, sonicate for 1h, then add 0.7g PVDF (molecular weight 4-100,000), stir for 4h until uniformly mixed, pour the mixture into a casting machine to form a film, and dry at 50°C for 3h. A flexible composite film is obtained.

...

Embodiment 3

[0042] Embodiment 3, preparation PVDF base flexible composite film

[0043] Weigh 2.54g of barium acetate, 1.73g of tetrabutyl titanate, and 1.4g of acetylacetone into 10ml of acetic acid in sequence and stir evenly, then add 0.4g of PVP (molecular weight: 1.3 million) and stir for 3 hours to form a stable sol. Electrospinning, the voltage is 15kV, the distance between the receiver and the needle is 10cm. The collected fibers were calcined at 950 °C for 6 h to obtain BaTiO 3 Nanofibers. Take 0.1g BaTiO 3 The nanofibers were placed in 10 mL of 0.01 mol / L dopamine aqueous solution, stirred in a water bath at 60° C. for 10 h, centrifuged, washed with ethanol, and dried to obtain BNFDopa nanofibers. The obtained BNFDopa nanofibers were added to 10 mL of DMF solvent, ultrasonicated for 1 h, then 0.8 g of PVDF was added, stirred for 4 h until uniformly mixed, the mixture was poured into a casting machine to form a film, and dried at 50°C for 3 h to obtain a flexible composite fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com