Visible-light-response antibacterial and antifouling polyvinylidene fluoride film and preparation method thereof

A technology of polyvinylidene fluoride membrane and polyvinylidene fluoride, which is applied in the field of preparation of modified ultrafiltration membranes, can solve the problems of not being able to effectively improve the antibacterial properties of PVDF membranes, and achieve reduced cleaning and maintenance costs, extended service life, and good antibacterial properties and anti-pollution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

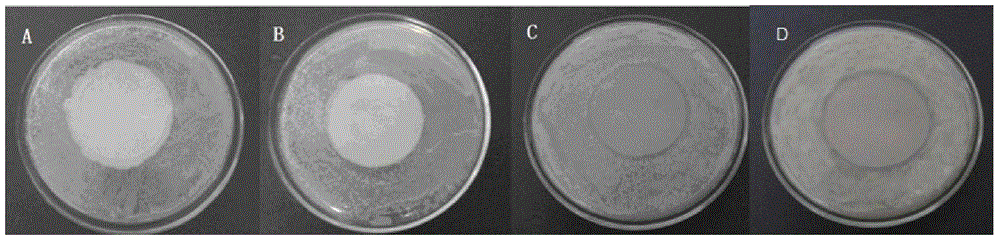

[0045] A visible light response antibacterial and antifouling polyvinylidene fluoride film, the preparation method of which comprises the following steps:

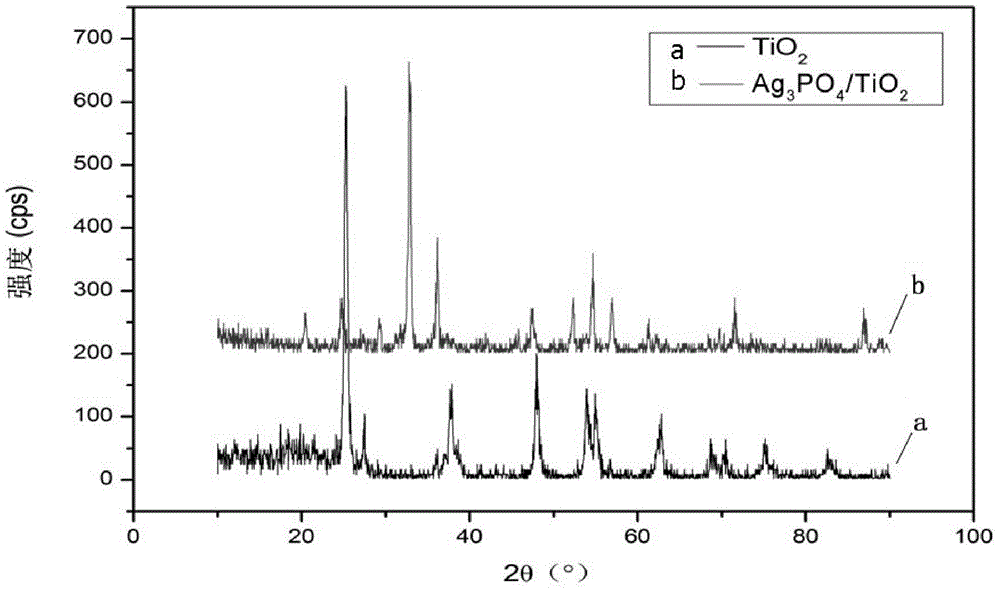

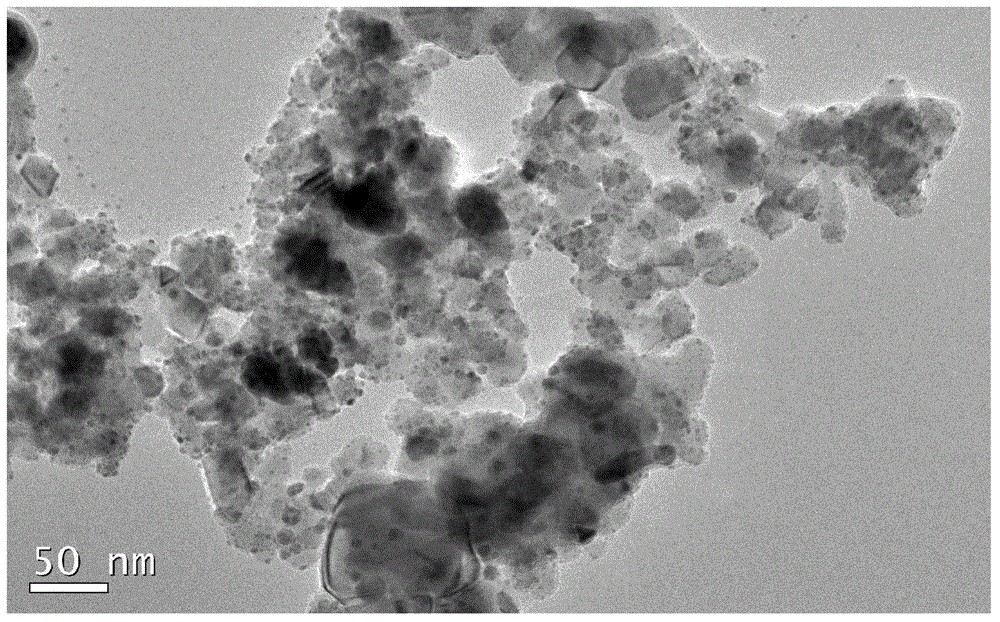

[0046] (1) Preparation of Ag 3 PO 4 / TiO 2 Composite: 1.56g of commercial TiO 2 (P25) was dispersed in 50ml of deionized water, after ultrasonication for 5min, 3g of AgNO was added 3 , mechanically stirred for 15min to obtain TiO 2 with AgNO 3 The mixture; the 2.3g Na 3 PO 4 12H 2 O was dissolved in 50ml deionized water to obtain a sodium phosphate solution, and then the sodium phosphate solution was added dropwise to the TiO 2 with AgNO 3 In the mixed solution, after the dropwise addition, continue to stir for 5h, filter and wash with suction, and finally dry at 60°C to obtain the Ag 3 PO 4 / TiO 2 Compound, stored in a dark place for later use;

[0047] (2) Preparation of polyvinylidene fluoride casting solution: get 0.067g of Ag obtained in step (1) 3 PO 4 / TiO 2 The compound was ultrasonically dispersed ...

Embodiment 2

[0052] A visible light-responsive antibacterial and antifouling polyvinylidene fluoride film, the preparation method of which comprises the following steps: a visible light responsive antibacterial and antifouling polyvinylidene fluoride film, the preparation method of which comprises the following steps:

[0053] (1) Preparation of Ag 3 PO 4 / TiO 2 Composite: 1g commercial TiO 2 (P25) was dispersed in 50ml deionized water, after ultrasonication for 5min, 4g AgNO was added 3 , mechanically stirred for 15min to obtain TiO 2 with AgNO 3 The mixture; the 2.3g Na 3 PO 4 12H 2 O was dissolved in 50ml deionized water to obtain a sodium phosphate solution, and then the sodium phosphate solution was added dropwise to the TiO 2 with AgNO 3 In the mixed solution, after the dropwise addition, continue to stir for 5h, filter and wash with suction, and finally dry at 60°C to obtain the Ag 3 PO 4 / TiO 2 Compound, stored in a dark place for later use;

[0054] (2) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com