Laminated-structure polymer-based dielectric energy-storage composite material and preparation method thereof

A composite material and polymer technology, applied in the field of polymer-based dielectric energy storage composite materials and their preparation, can solve problems such as reducing the breakdown field strength of polymers, and achieve improved electrical polarization characteristics, enhanced voltage resistance, high The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

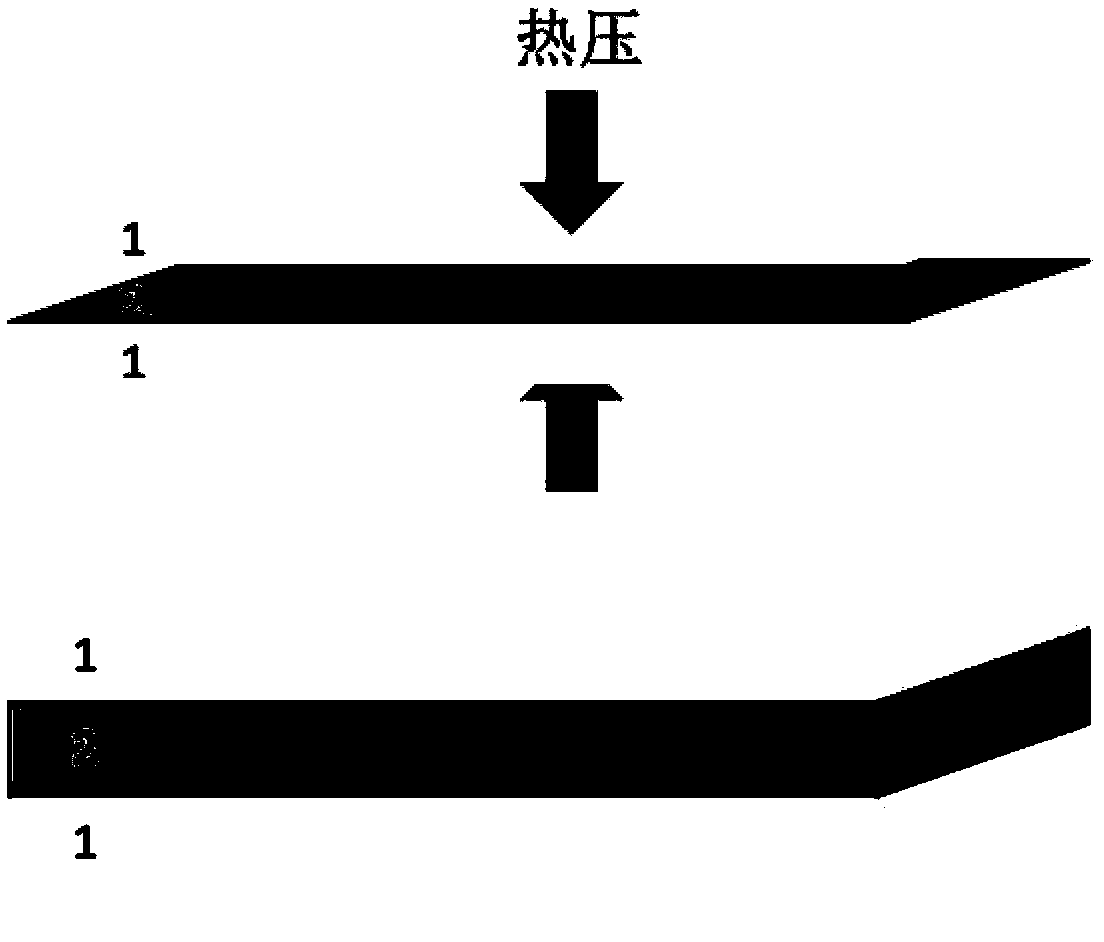

[0061] Embodiment 1, preparation laminated structure polymer matrix composite material

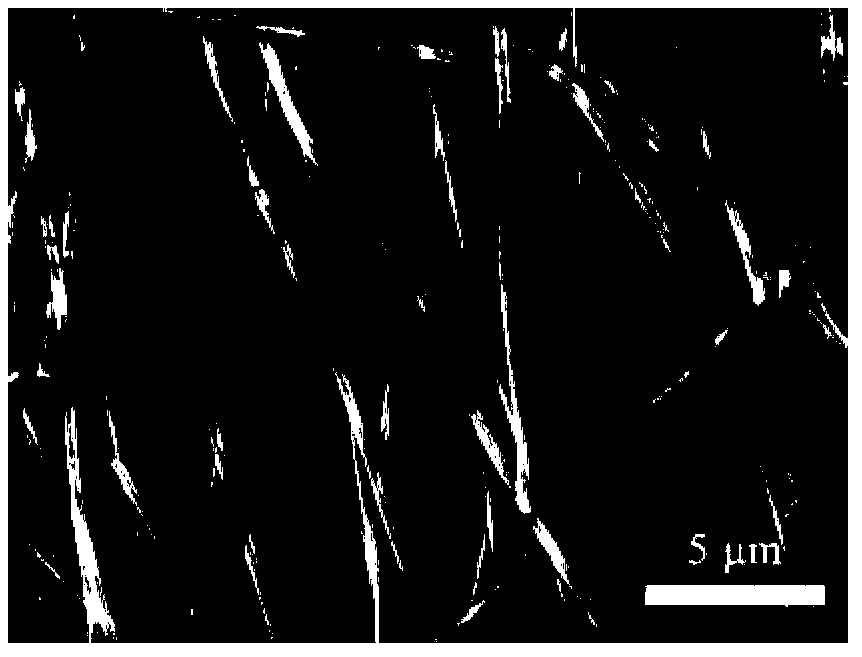

[0062] Weigh barium acetate (BaAc 2 ) 1.28g, strontium acetate (SrAc 2 0.5H 2 O) 1.07g, bismuth acetate (BiAc 3 )0.39g, tetrabutyl titanate ((C 4 h 9 O) 4 Ti) 3.91g, acetylacetone 2.00g were sequentially added to 9ml glacial acetic acid and stirred evenly, then 0.40g PVP (number average molecular weight 1.3 million) was added and stirred for 3h to form a stable sol, the sol was moved into a syringe for electrospinning, the voltage was 15kV, and the The distance between the device and the needle is 10cm. The collected precursor fibers were calcined at 700° C. for 3 h to obtain 2.2 g of strontium barium titanate (BSBT) nanofibers (with a diameter of 200-300 nm and a fiber length of 10-30 mm). Take 0.026g of BSBT nanofibers and place them in 10mL of 0.01mol / L dopamine aqueous solution, stir in a water bath at 60°C for 10h, centrifuge, wash with ethanol, and dry to obtain dopamine-coate...

Embodiment 2

[0067] Embodiment 2, preparation laminated structure polymer matrix composite material

[0068] Weigh barium acetate (BaAc 2 ) 1.28g, strontium acetate (SrAc 2 0.5H 2 O) 1.07g, bismuth acetate (BiAc 3 )0.39g, tetrabutyl titanate ((C 4 h 9 O) 4 Ti) 3.91g, acetylacetone 2.00g were sequentially added to 9ml glacial acetic acid and stirred evenly, then 0.40g PVP (number average molecular weight 1.3 million) was added and stirred for 3h to form a stable sol, the sol was moved into a syringe for electrospinning, the voltage was 15kV, and the The distance between the device and the needle is 10cm. The collected precursor fibers were calcined at 700° C. for 3 h to obtain 2.2 g of strontium barium titanate (BSBT) nanofibers (with a diameter of 200-300 nm and a fiber length of 10-30 mm). Take 0.026g BSBT nanofibers, add 10mL DMF solvent to it, sonicate for 1h, then add 1g PVDF (number average molecular weight 100,000), stir for 24h until uniformly mixed, pour the mixture into a cas...

Embodiment 3

[0071] Embodiment 3, preparation laminated structure polymer matrix composite material

[0072] Weigh 1.53g of barium acetate, 1.86g of strontium acetate, 3.40g of tetrabutyl titanate, and 1.80g of acetylacetone in 7ml of glacial acetic acid and stir evenly, then add 0.40g of PVP (number average molecular weight 1.3 million) and stir for 3 hours to form a stable Sol, move the sol into a syringe for electrospinning, the voltage is 14kV, and the distance between the receiver and the needle is 10cm. The collected precursor fibers were calcined at 650° C. for 3 h to obtain 2.5 g of barium strontium titanate (BST) nanofibers (with a diameter of 200-300 nm and a fiber length of 10-50 mm). Take 0.29g of BST nanofibers and place them in 20mL of 0.01mol / L dopamine aqueous solution, stir in a water bath at 60°C for 10h, centrifuge, wash with ethanol, and dry to obtain dopamine-coated barium strontium titanate nanofibers (BSTDopa). Add 10mL of DMF solvent, ultrasonic for 1h, then add 1g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com