Reactive butyl rubber self-adhesive layer for waterproof roll and processing technology thereof

A technology of butyl rubber and waterproof membrane, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., and can solve the problems of inability to find, separation of waterproof layer and main structure, maintenance Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

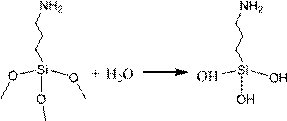

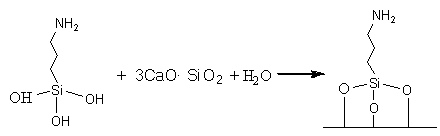

Method used

Image

Examples

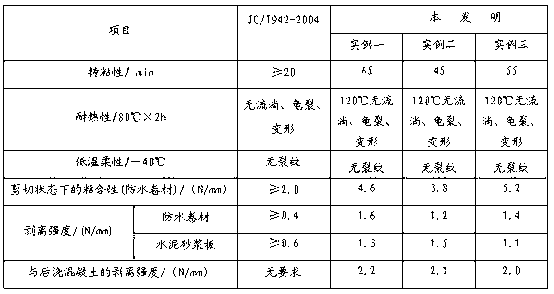

Embodiment 1

[0017] The parts by weight of the butyl rubber self-adhesive layer are: 20.0 parts of butyl rubber, 2.6 parts of ethylene vinyl acetate copolymer, 19.5 parts of tackifying resin, 22.8 parts of tackifier, 12.0 parts of carbon black, 12.0 parts of light calcium carbonate parts, 8.0 parts of functional additives, 1.8 parts of vulcanizing agent, 0.8 parts of anti-aging agent, and 0.5 parts of coupling agent.

[0018] The processing technology is as follows: put butyl rubber and ethylene vinyl acetate copolymer in a kneader, knead at a temperature of 120-140°C for 15-20 minutes, and add anti-aging agent, carbon black, light calcium carbonate, and thickener alternately in three batches Resin, functional additives and tackifier with a total mass of 80%, and then kneaded for 35-45 minutes to mix evenly, lower the temperature to below 100°C, add 20% of a total mass of tackifier, vulcanizing agent and coupling agent and knead for 15-20 minutes Finally, the material is discharged, and af...

Embodiment 2

[0020] The parts by weight of the butyl rubber self-adhesive layer are: 20.0 parts of butyl rubber, 1.0 part of ethylene vinyl acetate copolymer, 20.5 parts of tackifying resin, 18.4 parts of tackifier, 15.0 parts of carbon black, 14.0 parts of light calcium carbonate parts, 8.0 parts of functional additives, 1.8 parts of vulcanizing agent, 0.8 parts of anti-aging agent, and 0.5 parts of coupling agent.

[0021] The processing technology is as follows: put butyl rubber and ethylene vinyl acetate copolymer in a kneader, knead at a temperature of 120-140°C for 15-20 minutes, and add anti-aging agent, carbon black, light calcium carbonate, and thickener alternately in three batches Resin, functional additives and tackifier with a total mass of 80%, and then kneaded for 35-45 minutes to mix evenly, lower the temperature to below 100°C, add 20% of a total mass of tackifier, vulcanizing agent and coupling agent and knead for 15-20 minutes Finally, the material is discharged, and aft...

Embodiment 3

[0023] The parts by weight of the butyl rubber self-adhesive layer are: 20.0 parts of butyl rubber, 4.2 parts of ethylene vinyl acetate copolymer, 16.5 parts of tackifying resin, 24.0 parts of tackifier, 18.0 parts of carbon black, 9.0 parts of light calcium carbonate parts, 8.0 parts of functional additives, 1.8 parts of vulcanizing agent, 0.8 parts of anti-aging agent, and 0.5 parts of coupling agent.

[0024] The processing technology is as follows: put butyl rubber and ethylene vinyl acetate copolymer in a kneader, knead at a temperature of 120-140°C for 15-20 minutes, and add anti-aging agent, carbon black, light calcium carbonate, and thickener alternately in three batches Resin, functional additives and tackifier with a total mass of 80%, and then kneaded for 35-45 minutes to mix evenly, lower the temperature to below 100°C, add 20% of a total mass of tackifier, vulcanizing agent and coupling agent and knead for 15-20 minutes Finally, the material is discharged, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com