Edge sealing hot melt adhesive for furniture and preparation method thereof

A hot-melt adhesive and edge-sealing technology, used in adhesives, adhesive types, mineral oil-hydrocarbon copolymer adhesives, etc., which can solve the problems of complex process, low bonding strength, and small share.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

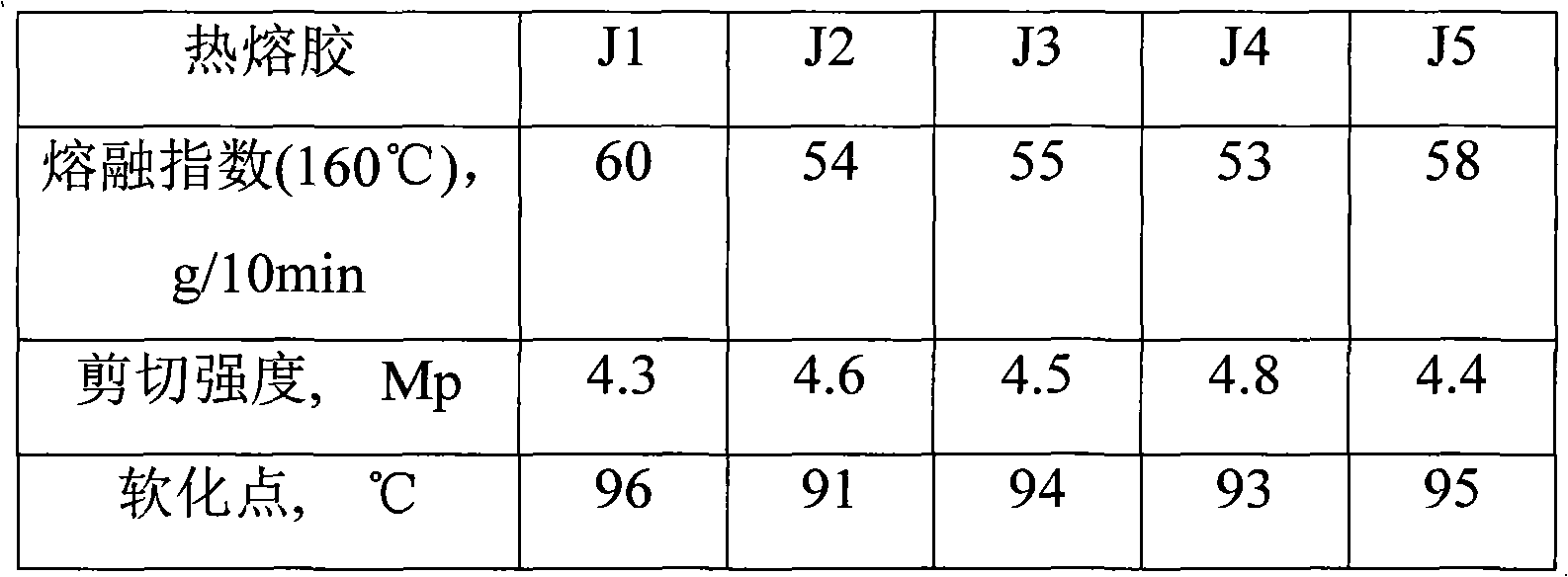

[0016] 30 parts of EVA with VA content of 28%, C 5 8.5 parts of petroleum resin, 12 parts of terpene resin, 3.6 parts of polyethylene wax, 2.4 parts of paraffin wax, 1.5 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, carbonic acid Add 24 parts of calcium (1250 mesh), 16 parts of talc powder (1250 mesh), 2 parts of dibutyl phthalate into the mixer, and knead at 100°C for 25 minutes; put the uniformly mixed product into the twin-screw extruder , the temperature of the inlet section, the middle section and the outlet section are respectively controlled at 80°C, 115°C, and 100°C. The extruded product is cooled and granulated to obtain the hot melt adhesive J1 for edge banding of furniture. Its basic physical properties are tested The results are shown in Table 1.

Embodiment 2

[0018] The VA content is 28% EVA48 parts, C 9 9 parts of petroleum resin, 10 parts of rosin, 1.8 parts of polyethylene wax, 1.2 parts of paraffin, 2 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, calcium carbonate ( 1250 mesh) 15 parts, talc powder (1250 mesh) 10 parts, dibutyl phthalate 3 parts into the mixer, 100 ° C mixing 25min; the mixed product was added to the twin-screw extruder, and The temperature of the inlet section, the middle section and the outlet section are respectively controlled at 85°C, 120°C, and 95°C. The extruded product is cooled and granulated to obtain the hot melt adhesive J2 for edge sealing of furniture. The test results of its basic physical properties are as follows: Table 1.

Embodiment 3

[0020] 40 parts of EVA with VA content of 28%, 10 parts of rosin, 5 parts of terpene resin, 3 parts of polyethylene wax, 2 parts of paraffin wax, four [β-(3,5-di-tert-butyl-4-hydroxyphenyl ) Propionic acid] 3 parts of pentaerythritol ester, 22 parts of calcium carbonate (1250 mesh), 13 parts of talcum powder (1250 mesh), 2 parts of dibutyl phthalate were added to the mixer, and mixed at 100 ° C for 25 minutes; The uniform product is fed into the twin-screw extruder, and the temperature of the inlet section, the middle section and the outlet section are respectively controlled at 90°C, 115°C, and 100°C, and the extruded product is cooled and granulated to obtain furniture edge banding. The test results of the basic physical properties of the hot melt adhesive J3 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com