Telemetering high-temp pressure resistant / differential pressure sensor

A differential pressure sensor, high temperature resistant technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve problems such as unseen pressure and differential pressure sensors, affecting performance and service life, and prone to short circuits , to achieve the effect of reducing the occupied space, reasonable structural design and reducing the influence of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

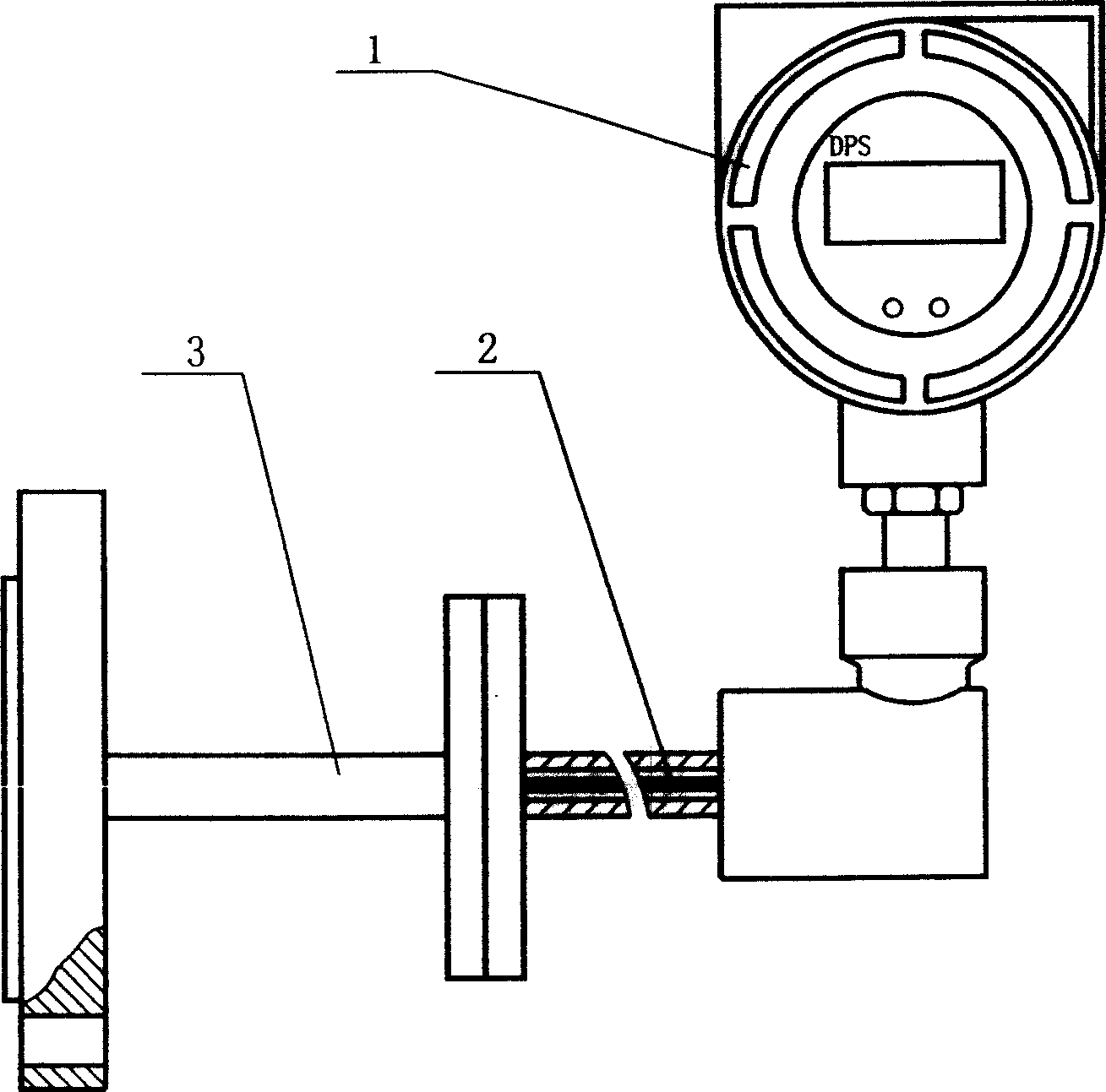

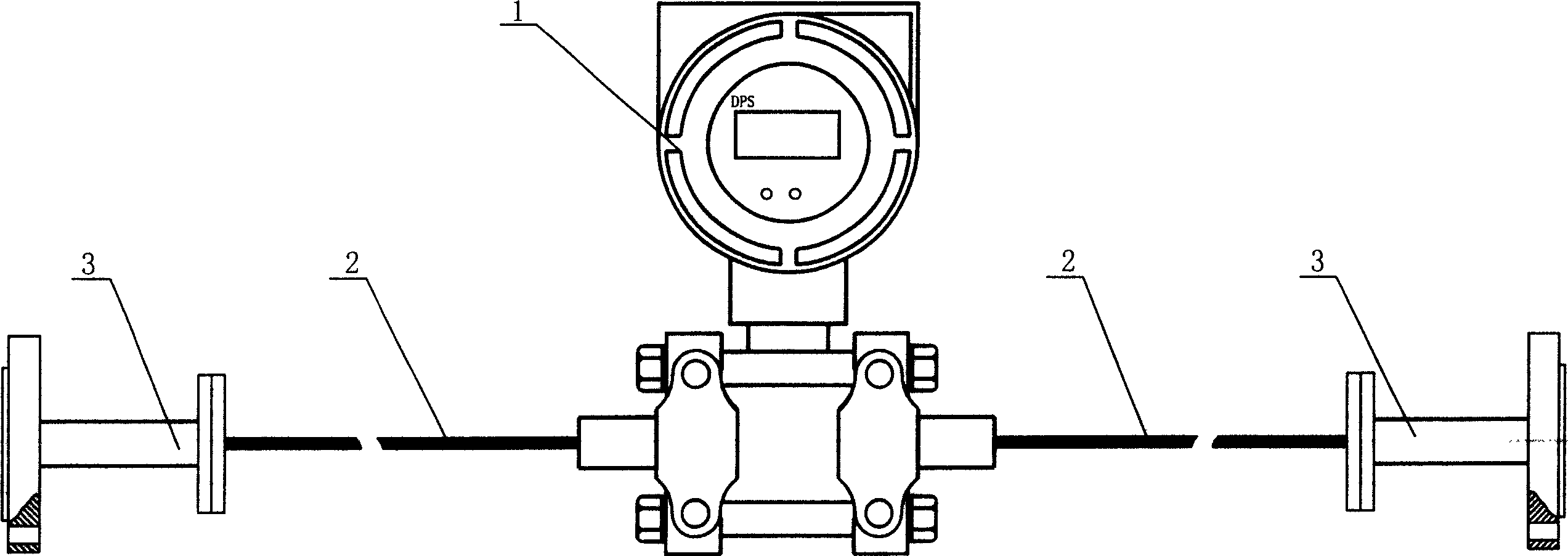

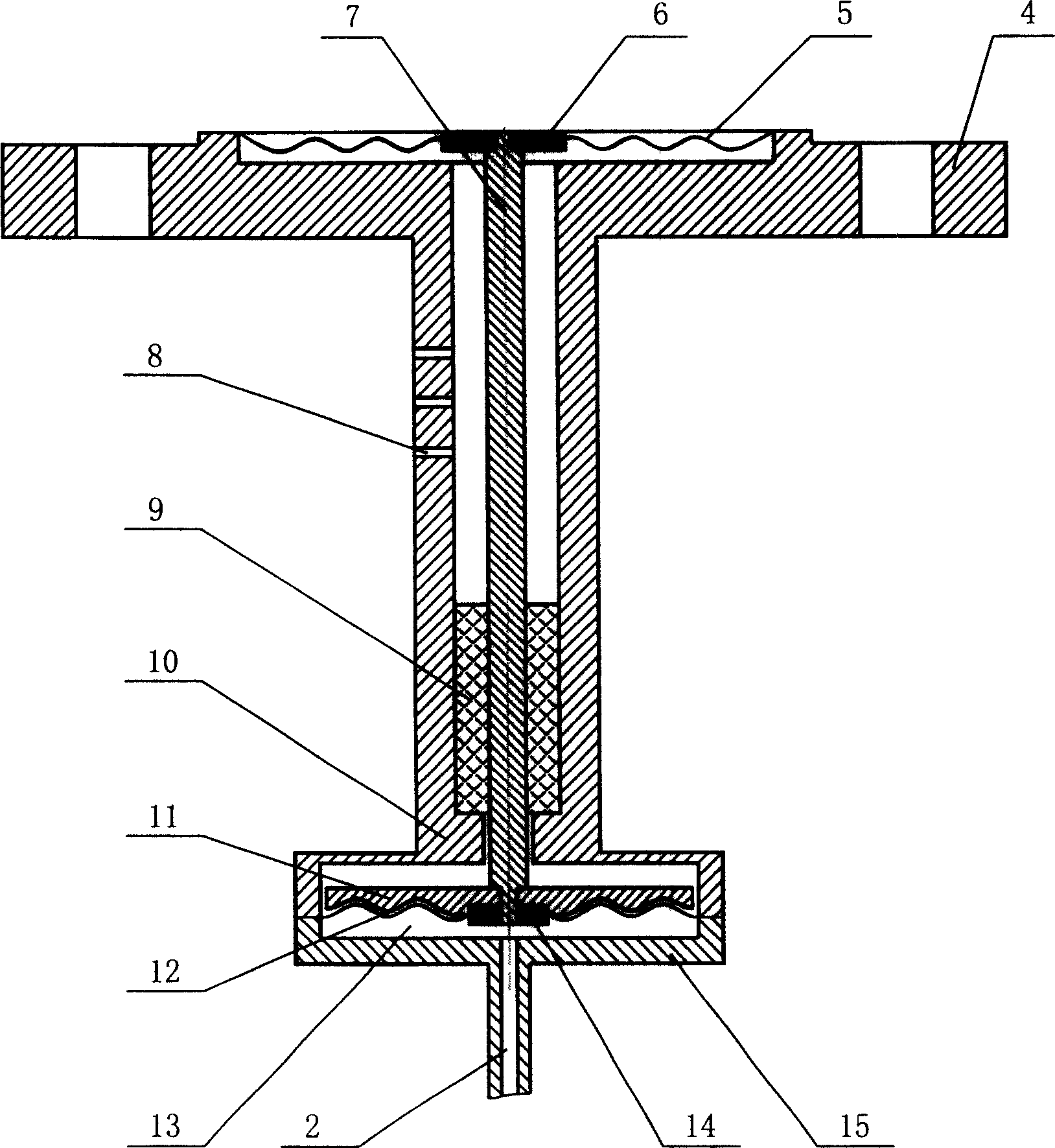

[0020] according to Figure 1-3 The specific structure of the present invention will be described in detail. The device can be used alone, constituted as figure 1 The structure of the pressure sensor (transmitter) shown can also be used together, such as figure 2 The differential pressure sensor (transmitter) structure shown. It includes a sensor 1 and a pressure guiding element 3 connected through a capillary 2, etc. Wherein the sensor 1 can adopt various types of commercially available sensors. The specification and size of the capillary 2 should be a commercially available capillary matching the temperature of the sensor 1 and the measured medium according to the requirements of use. The pressure guiding element 3 is composed of connecting flange 4, measuring diaphragm 5, diaphragm hard core 6, rigid stress rod 7, breathing hole 8, anti-vibration guide sleeve 9, support body 10, isolation diaphragm holder 11, isolation diaphragm 12. It is composed of liquid pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com