Stack-layered magnesium-air batteries

An air battery pack and air electrode technology, applied to fuel cell half-cells, primary battery half-cells, delayed action cells, etc., can solve the problems of complicated wiring, troublesome battery sealing, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

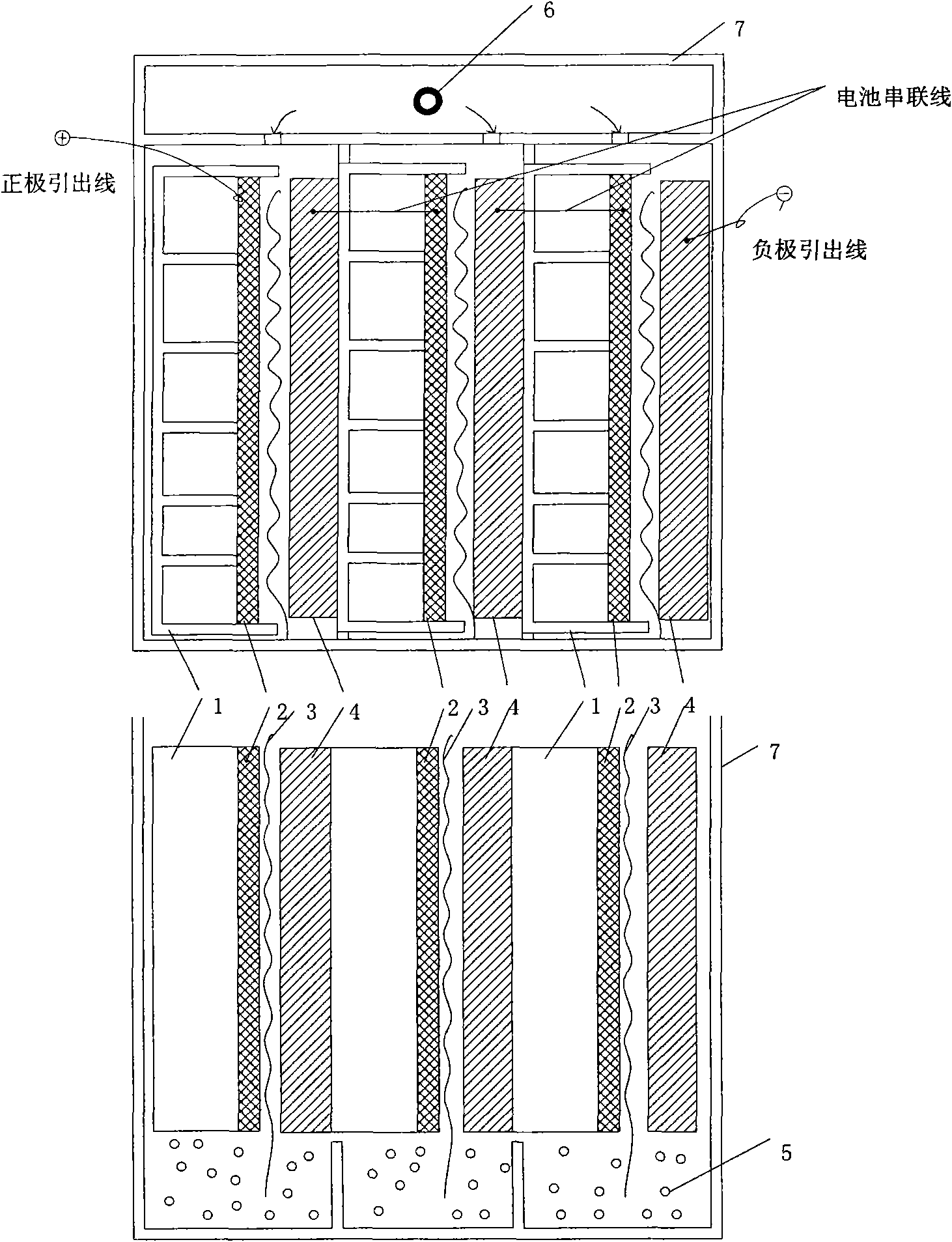

[0018] Embodiment 1: Portable laminated magnesium-air dry battery pack

[0019]The overall size of the battery pack is 50mm×30mm20mm matchbox, with a switch and a semiconductor light-emitting diode on the upper end. The performance parameters of the battery pack are: the average working voltage is 3 volts, the working current is 1-10 mA, and the capacitance is 2-4Ah. When lighting, the light bulb adopts a semiconductor light-emitting diode, which is equivalent to a candle or a low-light lighting lamp. It is mainly used for temporary or field lighting. The discharge time is 8 hours per day, and the working period is 2 months.

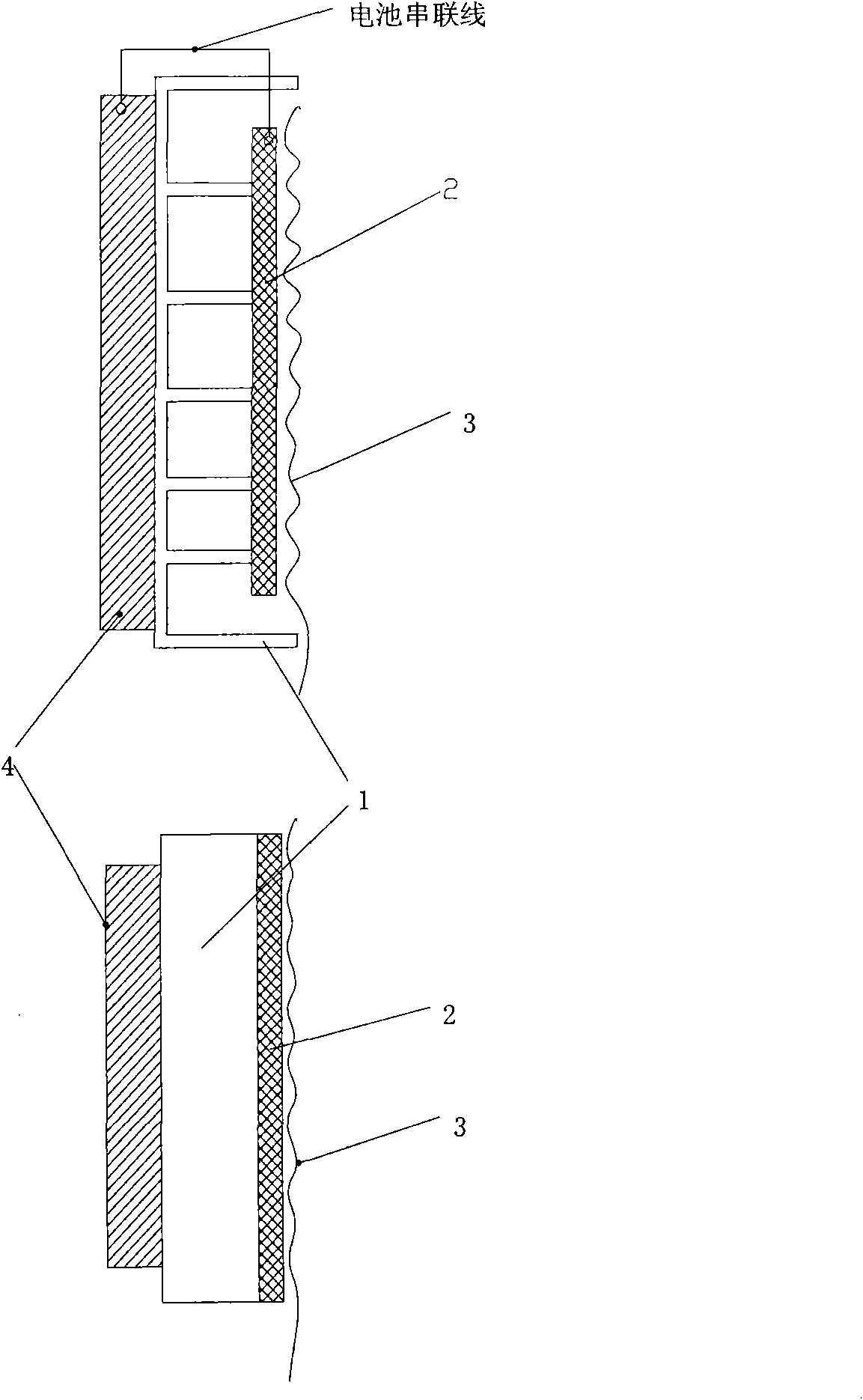

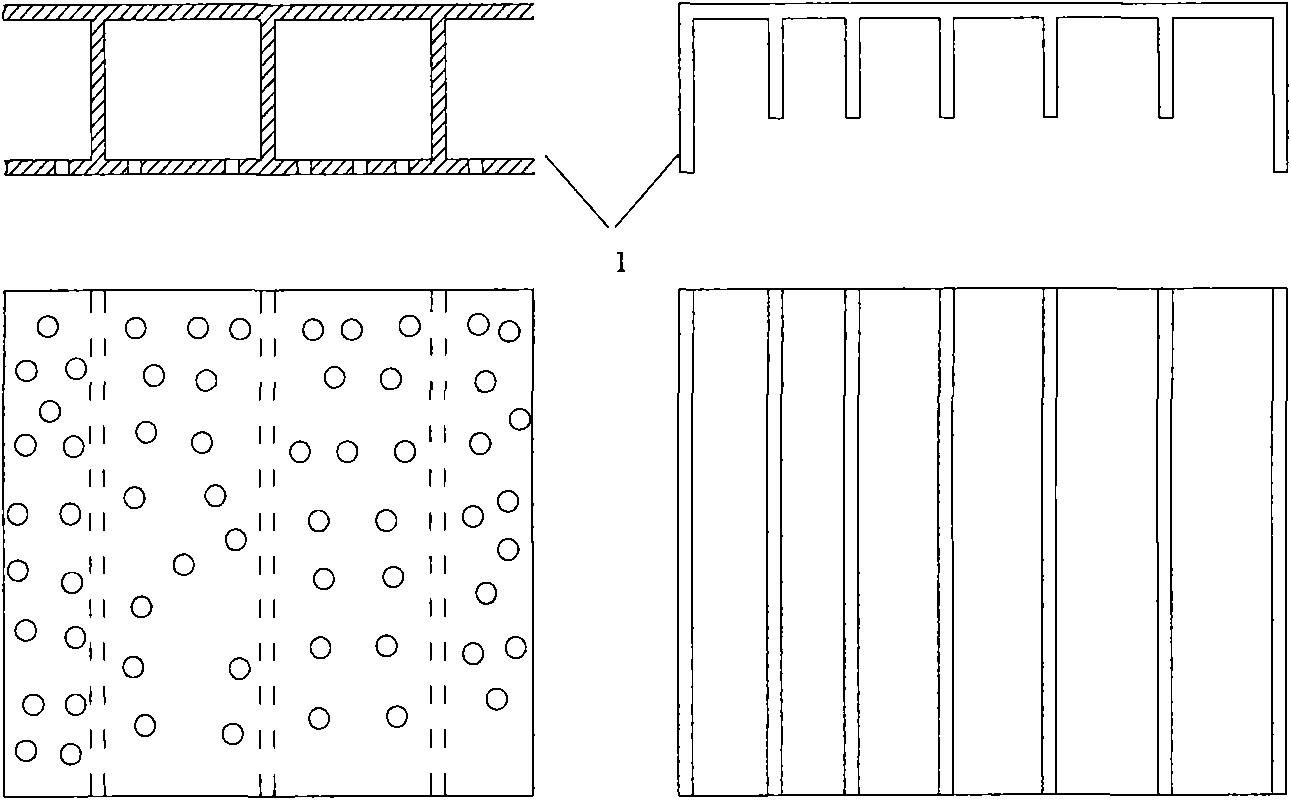

[0020] Batteries are compounded, manufactured and assembled according to the method described in the invention. Assemble the unit to isolate the gas transmission plate (comb-shaped, with a height of 2 mm between the teeth and a distance of 3 mm between the teeth). The air electrode is a thin plate with a thickness of about 0.5 mm, the paper diaphragm ...

Embodiment 2

[0022] Embodiment 2: emergency light power supply

[0023] Magnesium-water battery pack (six batteries per group), 6 volt, 0.5-2 watt magnesium-air battery pack, can store 140Wh of energy, and weighs more than 800 grams.

[0024] Batteries were fabricated and assembled according to the method described in the invention. The magnesium anode is made of AZ61 magnesium-aluminum-zinc magnesium alloy. The composition of the anode magnesium alloy is: Mg-6%Al-1.2%-0.45%Mn. It is smelted with high-purification technology, continuously cast into thin sheets and punched into a certain size as Anode sheet.

[0025] The unit parallel structure is adopted, and each single cell in the parallel structure has a separate battery room. 3 connected in parallel and then connected in series to form a battery pack. Other details are similar to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com