Preparation method of electric core

A cell and notch technology, which is applied in the field of cell preparation, can solve problems affecting cell performance, complicated process, and increased cost, and achieve the effects of saving coating paste, simple process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preparation method of the battery cell according to the present invention will be described in detail below with reference to the accompanying drawings.

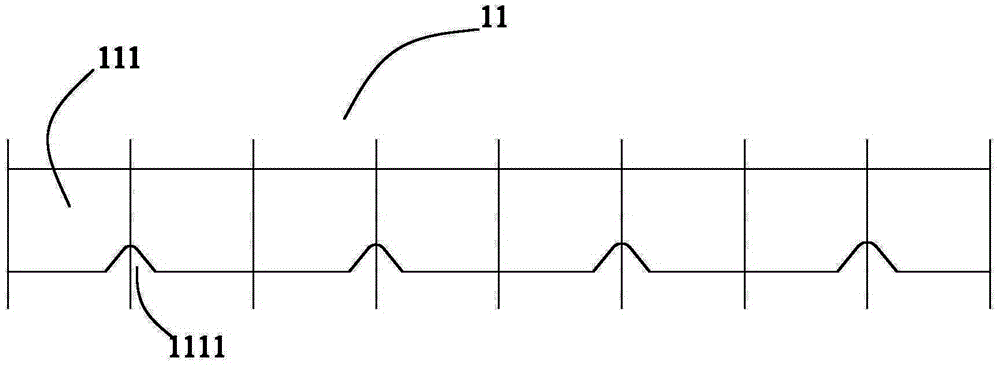

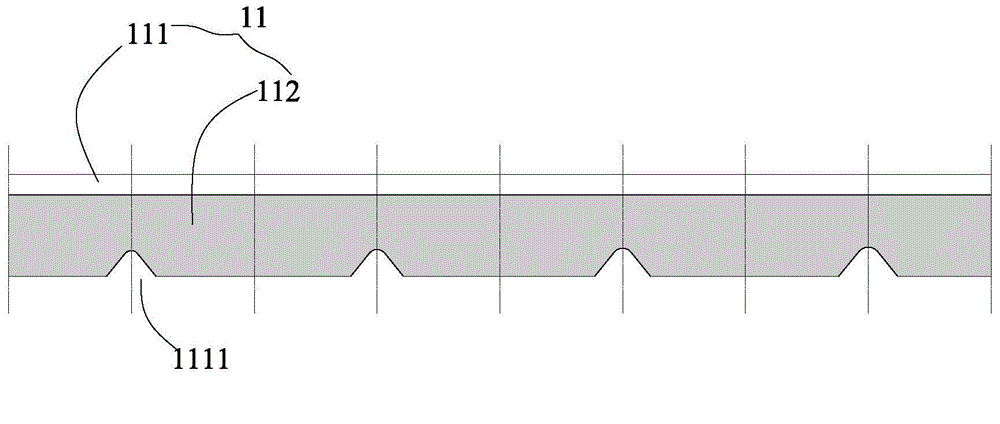

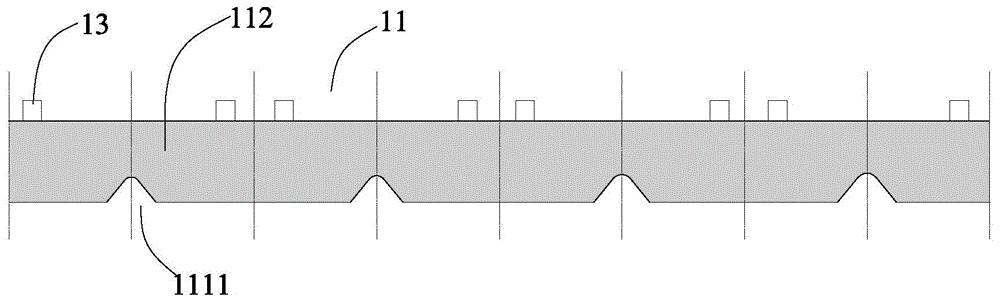

[0054] refer to Figure 1 to Figure 36, according to the preparation method of the electric core 1 of the present invention includes the manufacturing steps: preparing the first pole piece 11: first along the longitudinal direction of the first current collector 111 (the left and right direction in the figure) on the edge and / or inside of the first current collector 111 Cutting out the first gap 1111 in a linear array, and then coating the first slurry containing the first active material on the first current collector 111 and drying it, and the dried first slurry forms the first membrane 112, Finally, the first pole piece 11 is prepared by cold pressing; the second pole piece 12 is prepared: firstly, along the longitudinal direction of the second current collector 121, the first pole piece 111 is cut out at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com