Preparation method of meta-aramid nano-nets fiber membrane

A technology of fiber membrane and aramid fiber, which is applied in the field of preparation of meta-aramid nano-spider fiber membrane, which can solve the problems of thick fiber diameter and material application performance limitations, and achieve the effects of small fiber diameter, good fire resistance and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

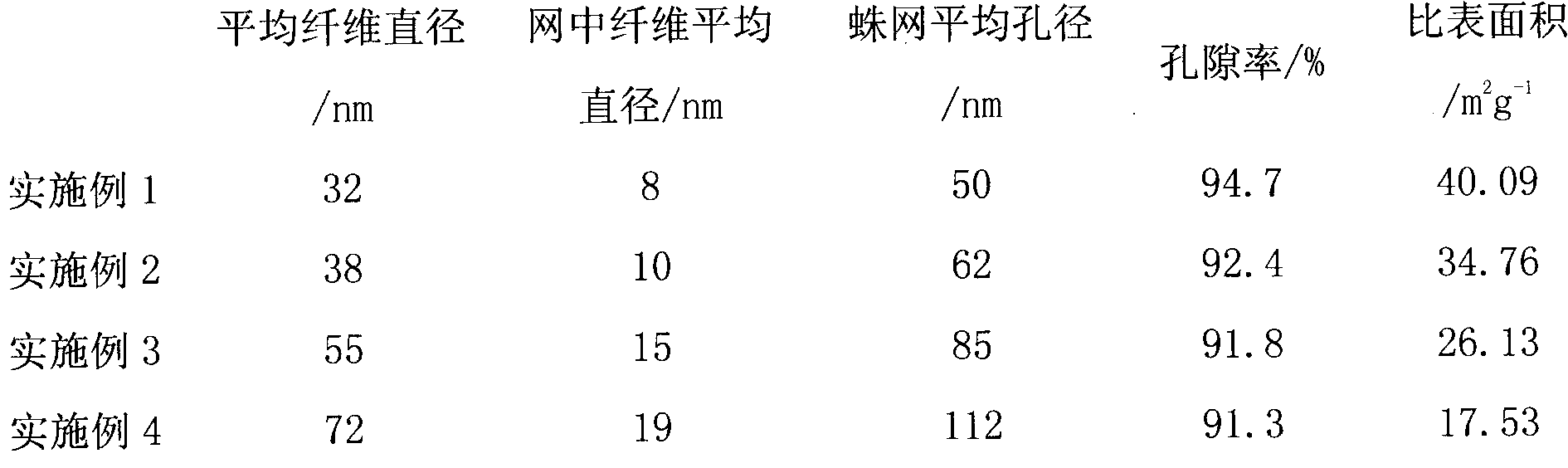

Examples

Embodiment 1

[0016] Lithium chloride is selected as the halogen salt; N, N-dimethylacetamide is selected as the organic solvent. Specific steps are as follows:

[0017] Step 1: Dissolve 0.1g of lithium chloride in 18.9g of N,N-dimethylacetamide at a room temperature of 25°C to prepare an ionic liquid solvent system;

[0018] Step 2: Add 1 g of meta-aramid to the ionic liquid solvent system obtained in the first step, stir with a stirrer until the meta-aramid is completely dissolved, and the mass fractions of meta-aramid and lithium chloride are respectively 5 %, 0.5% meta-aramid electrospinning raw materials;

[0019] Step 3: Under the condition of humidity of 35%, add the meta-aramid electrospinning raw material obtained in the second step into the electrospinning device, and the static voltage is 20kV, the flow rate of the syringe pump is 0.1mL / h, and the fiber is received Electrospinning is carried out under the condition of a distance of 8 cm to obtain a meta-aramid nano-spider web f...

Embodiment 2

[0021] The halogen salt is a mixture of calcium chloride and sodium chloride; the organic solvent is N,N-dimethylformamide. Specific steps are as follows:

[0022] Step 1: Add 0.8g of calcium chloride and sodium chloride (mass ratio 1:1) mixed halogen salt into 17.2g of N,N-dimethylformamide at room temperature of 25°C to prepare an ionic liquid solvent system;

[0023] The second step: add 2g of meta-aramid to the ionic liquid solvent system obtained in the first step, stir with a stirrer until the meta-aramid is completely dissolved, and obtain a mixed halide of meta-aramid, calcium chloride and sodium chloride The mass fraction of salt is respectively 10% and 4% meta-aramid electrospinning raw materials;

[0024] Step 3: Under the condition of 30% humidity, add the meta-aramid electrospinning raw material obtained in the second step into the electrospinning device. The electrostatic voltage is 30kV, the flow rate of the syringe pump is 1mL / h, and the fiber receives Elect...

Embodiment 3

[0026] The halogen salt is a mixture of lithium chloride and ferric chloride; the organic solvent is N-methylpyrrolidone. Specific steps are as follows:

[0027] Step 1: Add 1.2g of lithium chloride and ferric chloride (mass ratio 2:1) into 15.8g of N-methylpyrrolidone to dissolve at a room temperature of 25°C to prepare an ionic liquid solvent system;

[0028] The second step: add 3g of meta-aramid to the ionic liquid solvent system obtained in the first step, stir with a stirrer until the meta-aramid is completely dissolved, and obtain a mixed halide of meta-aramid, lithium chloride and ferric chloride The mass fraction of salt is respectively 15% and 6% meta-aramid electrospinning raw materials;

[0029] Step 3: Add the meta-aramid electrospinning raw material obtained in the second step to the electrospinning device under the condition of a humidity of 25%. When the static voltage is 45kV, the flow rate of the syringe pump is 2mL / h, and the fiber receives Electrospinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com