Polyolefin composite modified asphalt wet-laid waterproof roll and production method thereof

A technology of composite modified asphalt and waterproofing membrane, applied in the direction of asphalt layered products, chemical instruments and methods, synthetic resin layered products, etc. problems such as the decrease in adhesive force, to achieve the effect of long-lasting adhesive bonding, large adhesive force and large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

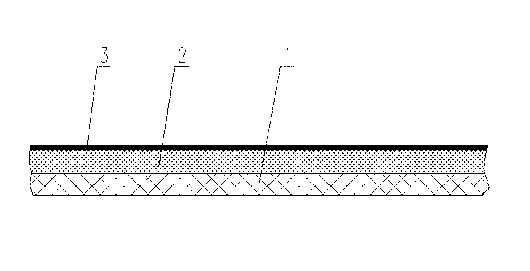

[0043] Production of a polyolefin composite modified asphalt wet paving waterproofing membrane, including a modified asphalt adhesive layer (2) capable of chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete, and a bonded isolation film protective layer (3), and polyolefin thermoplastic elastomer material layer (1), the interlayer structure is as follows: the first layer is polyolefin thermoplastic elastomer material layer (1), the middle layer is modified asphalt adhesive layer (2), The lower layer is the isolation film protection layer (3). The production method is to first prepare the modified asphalt adhesive layer and the polyolefin thermoplastic elastomer material layer that can have a chemical cross-linking reaction and a physical mortise and tenon synergistic bonding with the concrete. , the modified asphalt compound is coated on the thermoplastic polyolefin sheet, hot-pressed and bonded under the condition of 150-180 ℃, thick...

Embodiment 2

[0049] Production of a polyolefin composite modified asphalt wet paving waterproofing membrane, including a modified asphalt adhesive layer (2) capable of chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete, and a bonded isolation film protective layer (3), and polyolefin thermoplastic elastomer material layer (1), the interlayer structure is as follows: the first layer is polyolefin thermoplastic elastomer material layer (1), the middle layer is modified asphalt adhesive layer (2), The lower layer is the isolation film protection layer (3). The production method is to first prepare the modified asphalt adhesive layer and the polyolefin thermoplastic elastomer material layer that can have a chemical cross-linking reaction and a physical mortise and tenon synergistic bonding with the concrete. , the modified asphalt compound is coated on the thermoplastic polyolefin sheet, hot-pressed and bonded under the condition of 150-180 ℃, thick...

Embodiment 3

[0055]Production of a polyolefin composite modified asphalt wet paving waterproofing membrane, including a modified asphalt adhesive layer (2) capable of chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete, and a bonded isolation film protective layer (3), and polyolefin thermoplastic elastomer material layer (1), the interlayer structure is as follows: the first layer is polyolefin thermoplastic elastomer material layer (1), the middle layer is modified asphalt adhesive layer (2), The lower layer is the isolation film protection layer (3). The production method is to first prepare the modified asphalt adhesive layer and the polyolefin thermoplastic elastomer material layer that can have a chemical cross-linking reaction and a physical mortise and tenon synergistic bonding with the concrete. , the modified asphalt compound is coated on the thermoplastic polyolefin sheet, hot-pressed and bonded under the condition of 150-180 ℃, thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com