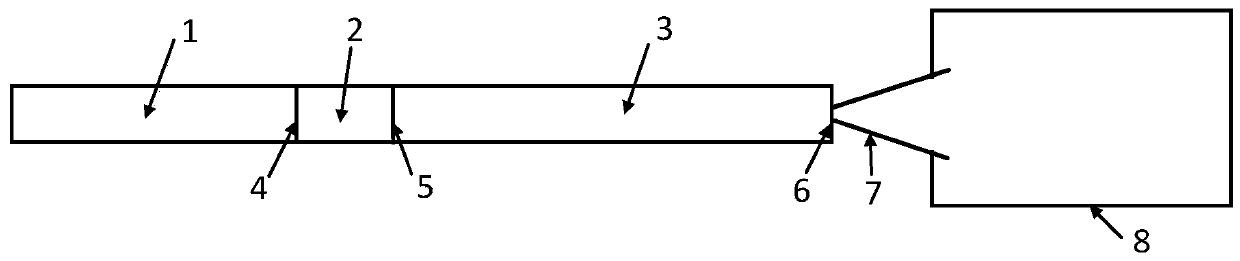

Shock tunnel with isolation device

A shock tunnel and isolation device technology, applied in the field of shock tunnels, shock tubes and shock tunnels, can solve the problems of test gas pollution, shortened test time, and inability to carry out tests normally, and achieve the purpose of suppressing combustion , Inhibit the burning of the contact surface and improve the reliability of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The working process of the shock tunnel with isolation device of the present invention is as follows:

[0027] Before the test, the driving section 1 is filled with high-pressure gas as the driving gas; the driven section 3 is initially filled with the test gas air, and the isolation section 2 is initially filled with the isolation gas nitrogen, and the driven section 3 and the isolation section 2 The initial inflation pressure is the same. During the test, when the high-pressure gas breaks through the main diaphragm 4, the high-pressure gas will first push the nitrogen in the compression isolation section 2 to generate the first shock wave that propagates downstream, and the nitrogen will break through the isolation after being pressurized, heated and accelerated by the shock wave Diaphragm 5 generates a second shock wave that propagates downstream. The shock wave pushes and compresses the air in the driven section 3, and generates a high-temperature and high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com