Preparation method of lamination battery cell

A cell and lamination technology, which is applied in the field of electrochemical energy storage devices, can solve the problems of long auxiliary time, production efficiency to be improved, and high performance requirements such as the durability of the isolation film slitting device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following detailed description describes exemplary embodiments and is not intended to be limited to the expressly disclosed combinations. Accordingly, unless otherwise stated, various features disclosed herein may be combined together to form additional combinations not shown for the sake of brevity.

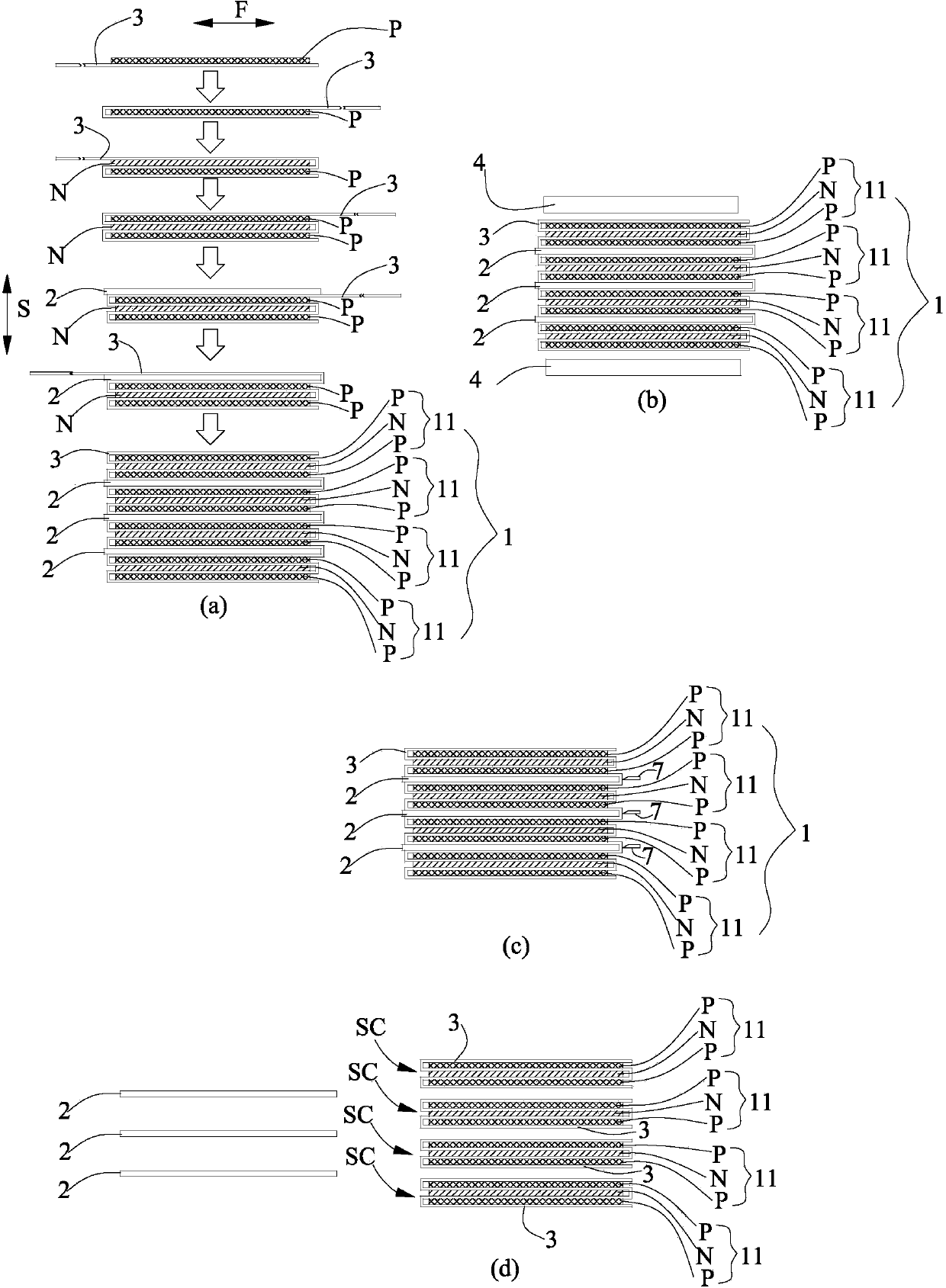

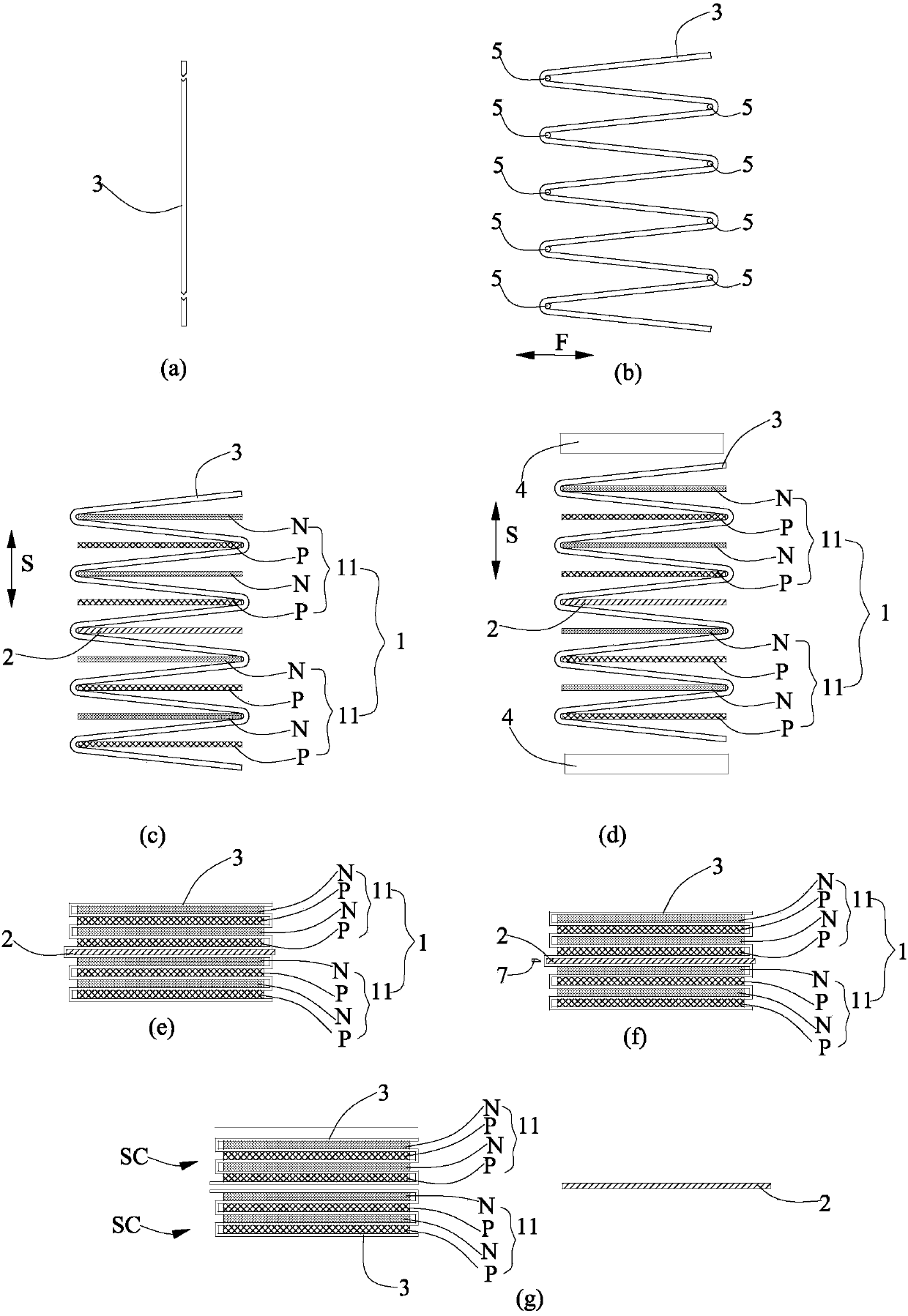

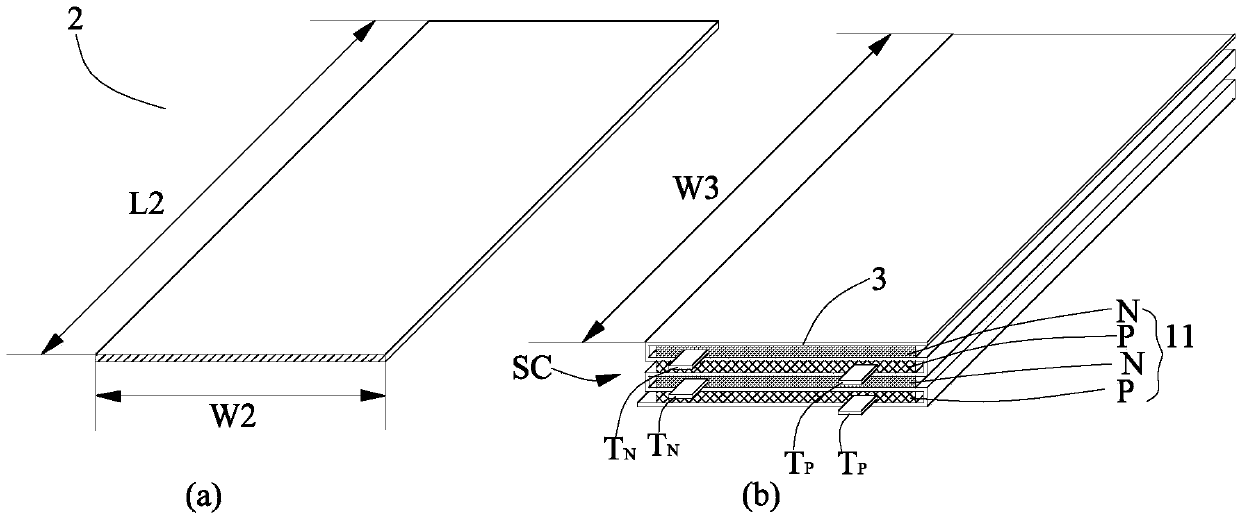

[0035] refer to figure 1 , figure 2 , Figure 6 , Figure 9 According to the preparation method of the laminated electric core of the present invention, it includes the steps of: setting the lamination stack: the lamination stack 1 includes n lamination groups 11, each lamination group 11 includes m pole piece elements and each lamination group 11 The number of pole piece elements included is the same (refer to figure 1 , figure 2 , Figure 6 , Figure 9 ) or different, wherein n≥2, m≥2, gaskets 2 are arranged between adjacent lamination groups 11, the pole piece elements of all lamination groups 11 of lamination stack 1 and adjacent lamination groups 11 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com