Method for continuously producing jelly of ultra-high molecular weight polyethylene porous membrane

A technology of ultra-high molecular weight and production method, which is applied in the field of continuous gel production of ultra-high molecular weight polyethylene porous membrane, and can solve problems such as restricting the development of proton exchange membrane fuel cells, having no commercial use value, and uneven pore size of porous membranes. Achieve the effects of strong anti-swelling ability, easy control and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

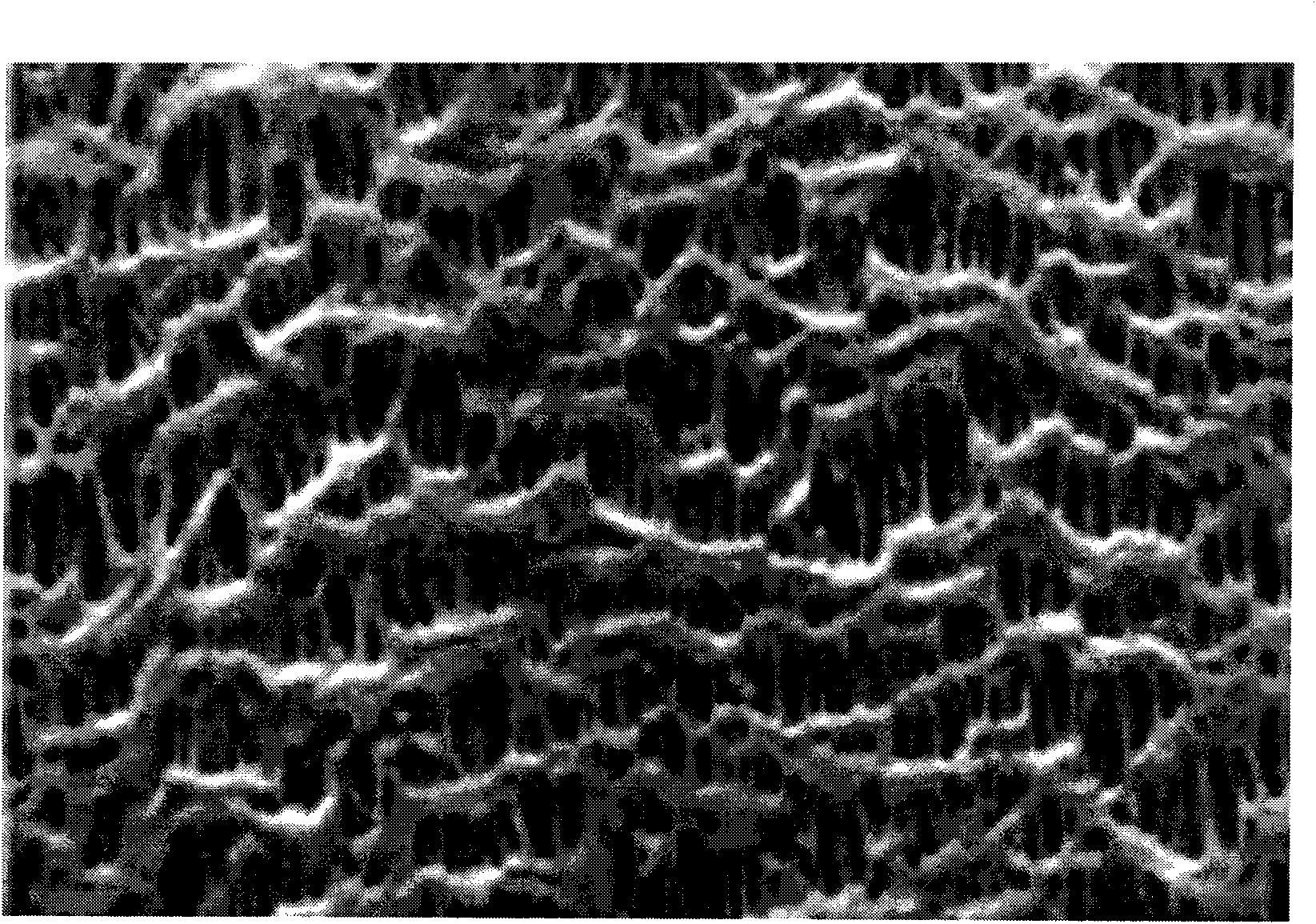

Image

Examples

Embodiment 1

[0029] Fabrication of ultra-high molecular weight polyethylene porous membranes for proton exchange membrane fuel cells. The jelly continuous production method of the ultra-high molecular weight polyethylene porous membrane is characterized in that: it comprises the following steps of continuous production:

[0030] (1) Mix ultra-high molecular weight polyethylene with a molecular weight of 3 million, solvents and additives into a homogeneous material:

[0031] The used solvent is mineral white oil, and the addition is 82% of the ultra-high molecular weight polyethylene weight;

[0032] The additive is B225 antioxidant, produced by Shanghai Fuqi Chemical Co., Ltd., and the addition amount is 0.03% of the weight of ultra-high molecular weight polyethylene;

[0033] The ultra-high molecular weight polyethylene powder, solvent and additives are automatically weighed through the weight loss metering system, and simultaneously transported to the online high-shear emulsifier for ho...

Embodiment 2

[0046] Ultra-high molecular weight polyethylene porous membranes for water treatment membranes. The jelly continuous production method of the ultra-high molecular weight polyethylene porous membrane is characterized in that: it comprises the following steps of continuous production:

[0047] (1) Mix ultra-high molecular weight polyethylene with a molecular weight of 7 million, solvents and additives into a homogeneous material:

[0048] The used solvent is mineral white oil, and the addition is 94% of the ultra-high molecular weight polyethylene weight;

[0049] The additive is B225 antioxidant, and the addition is 0.03% of the weight of ultra-high molecular weight polyethylene;

[0050] The ultra-high molecular weight polyethylene powder, solvent and additives are automatically weighed through the weight loss metering system, and transported to the high-shear emulsifier for homogenization, and the temperature is controlled at 30°C;

[0051] (2), the obtained homogenized mater...

Embodiment 3

[0063] Ultra-high molecular weight polyethylene porous membranes for the production of separation membranes. The jelly continuous production method of the ultra-high molecular weight polyethylene porous membrane is characterized in that: it comprises the following steps of continuous production:

[0064] (1), mixing ultra-high molecular weight polyethylene with a molecular weight of 5 million, solvents and additives into a homogeneous material:

[0065] The solvent used is mineral white oil, and the addition is 70% of the ultra-high molecular weight polyethylene weight;

[0066] The additive is B225 antioxidant, and the addition is 0.05% of the weight of ultra-high molecular weight polyethylene;

[0067] The ultra-high molecular weight polyethylene powder, solvent and additives are automatically weighed through the weight loss metering system, and transported to the high-shear emulsifier for homogenization, and the temperature is controlled at 60°C;

[0068] (2), the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com