Lithium negative pole, preparation method thereof and battery comprising lithium negative pole

A lithium negative electrode and battery technology, which is applied in the field of electrochemical batteries, can solve the problems of cycle performance degradation and large changes in the surface morphology of lithium powder electrodes, improve safety performance and cycle performance, reduce the probability of dendrite formation, and The effect of a large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

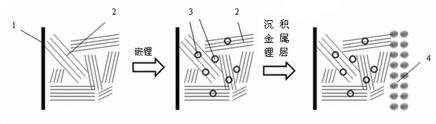

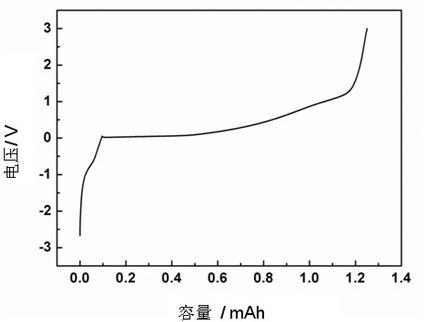

[0027] Mesocarbon microspheres (MCMB) are used as lithium carriers, mixed with conductive agent carbon black (SP) and binder polyvinylidene fluoride (PVDF) at a mass ratio of 91:3:6, and N-methyl-2- Pyrrolidone (NMP) was used as a solvent, mixed with a high-speed emulsifier to form a slurry, and evenly coated on the Cu foil of the current collector, and then dried in a vacuum oven at 60 °C for 24 h, and set aside. With metal lithium sheet as the negative electrode, mesocarbon microspheres as the counter electrode, Celgrad 2325 as the diaphragm, 1.2 mol / L lithium hexafluorophosphate (LiPF 6 ) / ethylene carbonate (EC) + methyl ethyl carbonate (EMC) (volume ratio 3:7) as the electrolyte to assemble the battery.

[0028] The battery was first charged and discharged at a current density of 40 mA / g, and the voltage range was 0-3 V. After 10 cycles, it was discharged to 0 V, and then discharged at a constant current density of 40 mA / g for 9 h to electrochemically deposit a lithium me...

Embodiment 2

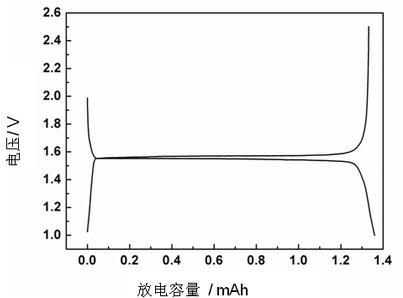

[0030] Graphite (MCP-1) is used as the lithium carrier, mixed with conductive agent carbon black (SP) and binder polyvinylidene fluoride (PVDF) at a mass ratio of 91:3:6, and N-methyl-2-pyrrolidone ( NMP) was used as a solvent, mixed with a high-speed emulsifier to form a slurry, and evenly coated on the Cu foil of the current collector, and then dried in a vacuum oven at 60 °C for 24 h, and set aside. With lithium metal sheet as negative electrode, graphite as counter electrode, Celgrad 2325 as diaphragm, 1.2 mol / L lithium hexafluorophosphate (LiPF 6 ) / ethylene carbonate (EC) + methyl ethyl carbonate (EMC) (volume ratio 3:7) + fluoroethylene carbonate (FEC, 5wt%) as the electrolyte to assemble the battery.

[0031] The battery was first charged and discharged at a current density of 31 mA / g, and the voltage range was 0-2 V. After 10 cycles, discharge to 0V, and then discharge at a constant current density of 31 mA / g for 5 h, and electrochemically deposit a lithium metal laye...

Embodiment 3

[0033] Using hard carbon (HC) as the lithium carrier, mixed with conductive agent carbon black (SP), conductive agent vapor phase grown carbon fiber (VGCF), and binder polyvinylidene fluoride (PVDF) at a mass ratio of 92:2:1:5, Using N-methyl-2-pyrrolidone (NMP) as a solvent, the slurry was mixed with a high-speed emulsifier and evenly coated on the Cu foil of the current collector, and then dried in a vacuum oven at 60 °C for 24 h, ready for use. With metal lithium sheet as the negative electrode, hard carbon as the counter electrode, Celgrad 2325 as the diaphragm, 1.2 mol / L lithium hexafluorophosphate (LiPF 6 ) / ethylene carbonate (EC) + methyl ethyl carbonate (EMC) (volume ratio 3:7) as the electrolyte to assemble the battery.

[0034] The battery was first charged and discharged at a current density of 40 mA / g, and the voltage range was 0-3 V. After 10 cycles, discharge to 0 V, and then discharge at a constant current density of 40 mA / g for 4 h, and electrochemically depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com