Method for preparing anode material doped with LiVPO4F for lithium ion battery

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability, achieve the effects of improving conductivity, shortening the process flow, and excellent charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

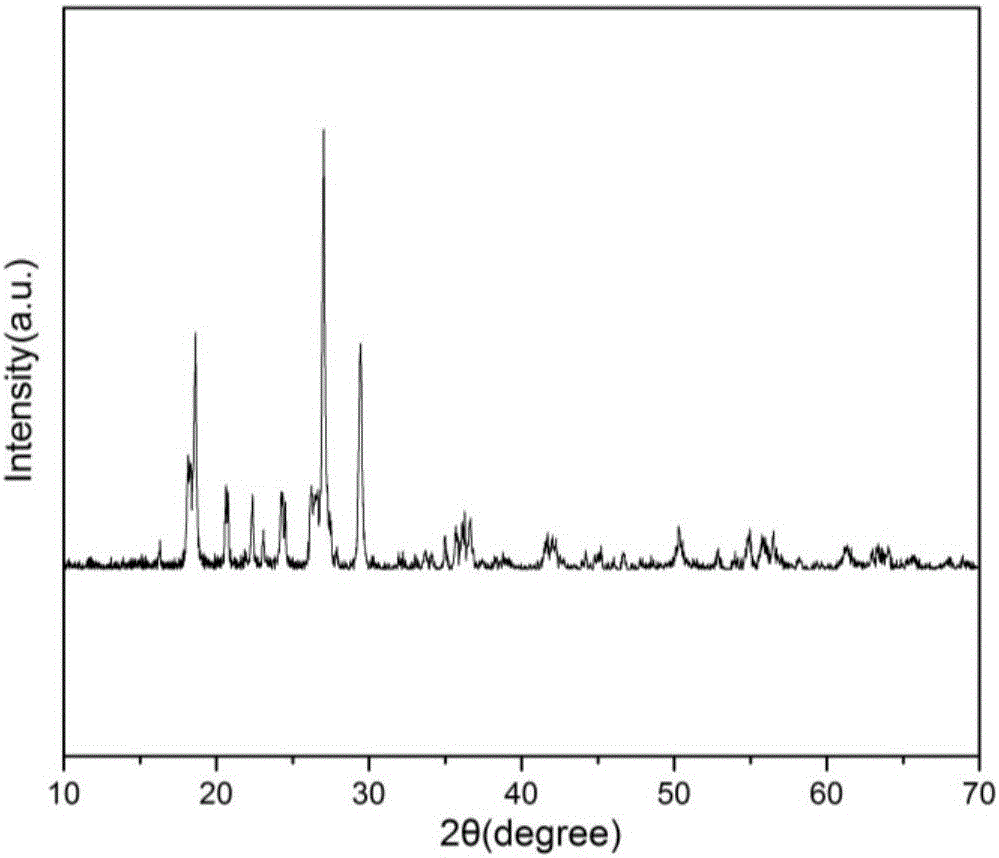

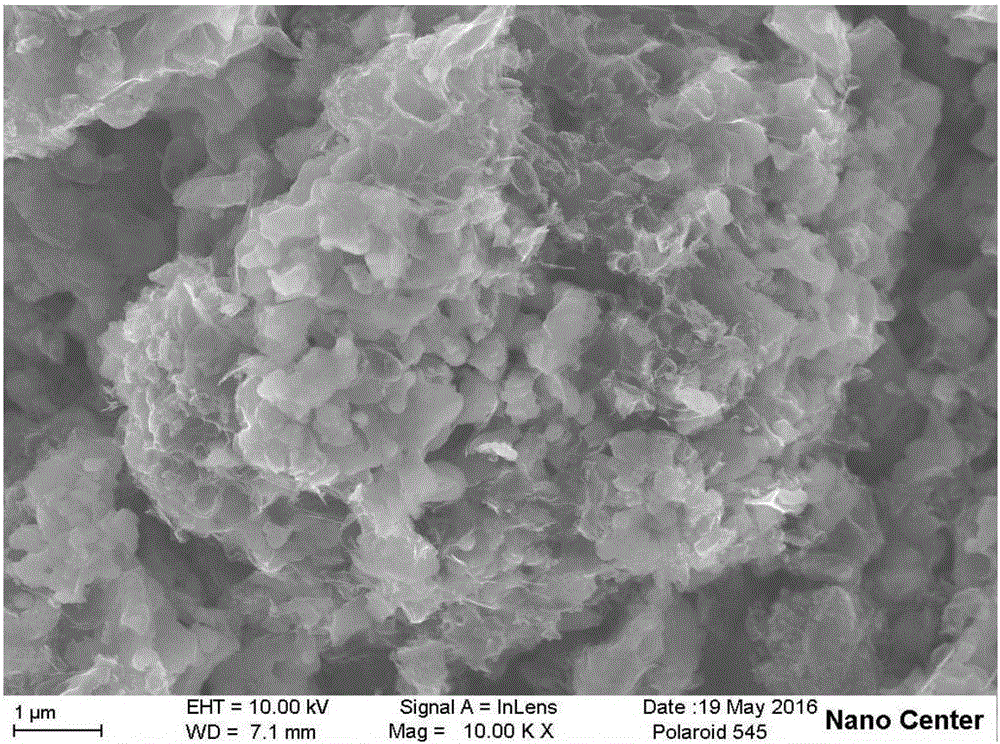

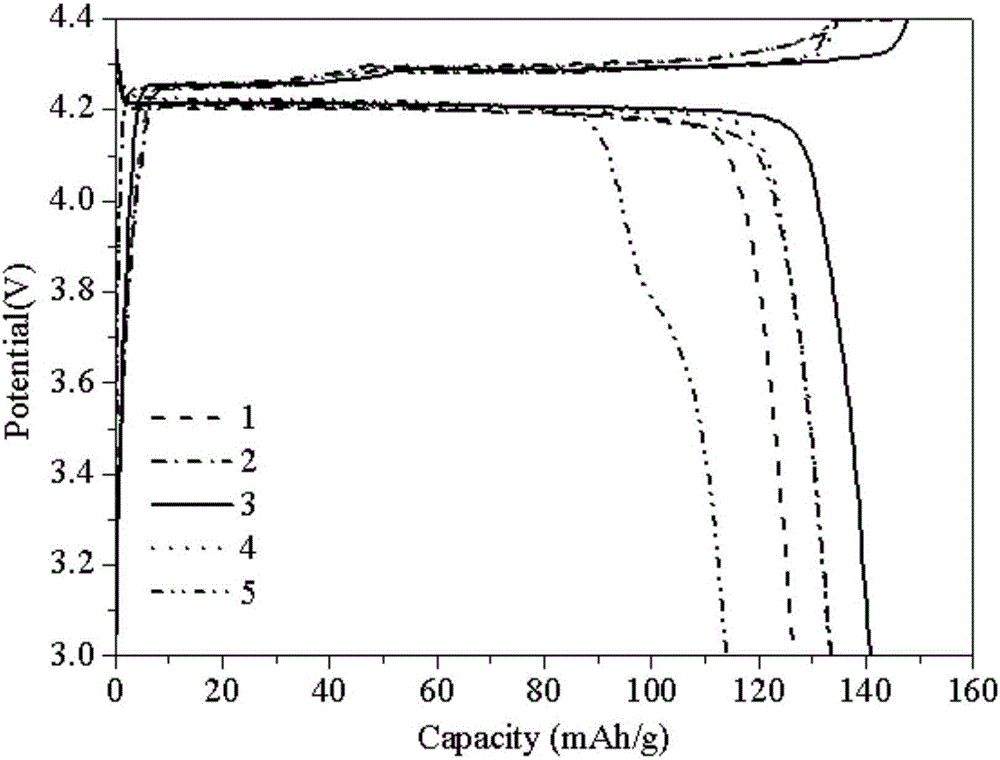

Embodiment 1

[0041]Lithium fluoride, vanadium pentoxide, ammonium dihydrogen phosphate, titanium trifluoride, citric acid, and phenolic resin are used as raw materials (titanium trifluoride is used as the fluorine source and metal compound), and the ingredients are stoichiometrically proportioned. Titanium trifluoride The doping amount is 1%, the molar ratio of citric acid and vanadium is 1:1, and the carbon source accounts for 5% of the total weight. Distilled water is used as a solvent to prepare a solution with a concentration of 0.15mol / l, and it is formed by rapid magnetic stirring at 85°C. After the thick solution was dried in vacuum, the drying temperature was 90°C, and the temperature was kept for 16h. After grinding and sieving, the powder obtained was calcined at 650°C, 700°C, 750°C, 800°C and 850°C for 4h in an argon atmosphere to obtain LiVPO 4 F powder, the resulting sample is assembled into a button cell for electrochemical performance testing. Charge and discharge at differe...

Embodiment 2

[0045] Lithium carbonate, vanadium dioxide, diammonium hydrogen phosphate, lithium fluoride, chromium trifluoride, oxalic acid, sucrose as raw materials, lithium, vanadium, phosphorus, fluorine molar ratio 1:1:1:1, chromium trifluoride The doping amount is 5%; the oxalic acid: vanadium molar ratio is 2:1, the carbon source accounts for 15% of the total proportion, and distilled water is used as a solvent to configure a solution with a concentration of 0.25mol / l, which is formed by rapid magnetic stirring at 50°C. After drying the solution, the drying temperature is 100°C, and the temperature is kept for 10h. After grinding and sieving, the powder obtained is calcined at 800°C for 2, 4, 6, 10, 14h in an argon atmosphere to obtain LiVPO 4 F powder, the resulting sample is assembled into a button cell for electrochemical performance testing. Charge and discharge at different rates, the specific capacity of the first charge and discharge is shown in Table 2.

[0046] Experimental...

Embodiment 3

[0049] Lithium acetate, ammonium metavanadate, triammonium phosphate, ammonium trifluoride, aluminum fluoride, malic acid, and polyvinylidene fluoride are used as raw materials, and the molar ratio of lithium, vanadium, phosphorus, and fluorine is 1:1:1:1 , the doping amount of aluminum fluoride is 1%, 2%, 3%, 4%, 5% respectively, malic acid: vanadium molar ratio is 1.5:1, carbon source accounts for 10% of total proportion, is configured with distilled water as solvent A solution with a concentration of 0.2 mol / l is stirred rapidly at 90°C to form a viscous solution, then vacuum-dried at a drying temperature of 95°C and kept for 12 hours. After grinding and sieving, the powder obtained is calcined at 800°C for 4 hours in an argon atmosphere. Get LiVPO 4 F powder, the resulting sample is assembled into a button cell for electrochemical performance testing. Charge and discharge at different rates, the specific capacity of the first charge and discharge is shown in Table 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com