Nickel cobalt base-carbon nanotube composite electrode material and preparation method thereof

A composite electrode and carbon nanotube technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of reduced utilization of active materials, higher requirements for reaction conditions, and reduced electrochemical activity. The effect of agglomeration, easy dispersion and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 213.9mg of nickel chloride, 142.8mg of cobalt chloride and 427.9mg of ammonium chloride respectively, dissolve them in 30mL of deionized water, mix them evenly, and perform ultrasonic treatment on the mixed solution for 10min to 30min, then continue to stir the solution rapidly .

[0028] (2) Weigh 110mg of sodium hydroxide, dissolve it in 10mL of deionized water, quickly pour the sodium hydroxide solution into the stirred mixed solution, continue to stir for 10min, seal the reaction bottle and place it in a 55°C oil bath, Take it out after reacting for 15 hours. After the reaction bottle is cooled to room temperature, you can see a green precipitate at the bottom of the bottle, filter it with suction, wash it with deionized water several times, and dry it in an oven at 60°C for 24 hours.

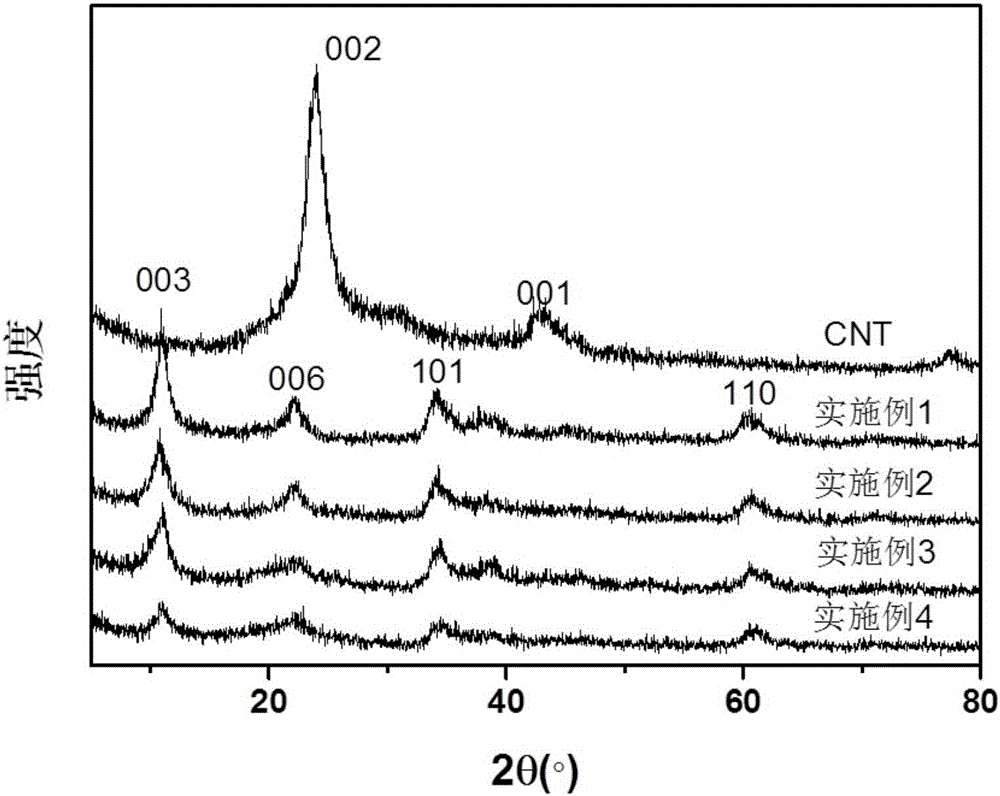

[0029] The XRD spectrum of the supercapacitor electrode material nickel-cobalt double metal hydroxide prepared in the present embodiment is as follows figure 1 As shown in...

Embodiment 2

[0034] (1) Weigh 17.8 mg of carbon nanotubes modified with oxygen-containing functional groups, dissolve them in 30 mL of deionized water, and disperse them by ultrasonication for 20 min to 120 min.

[0035] (2) Weigh 213.9mg of nickel chloride, 142.8mg of cobalt chloride and 427.9mg of ammonium chloride respectively, dissolve them in the carbon nanotube solution in (1), and after mixing evenly, carry out ultrasonic treatment on the mixed solution for 10min to 30min , and then continue to stir the solution rapidly.

[0036] (3) Weigh 110mg of sodium hydroxide, dissolve it in 10mL of deionized water, quickly pour the sodium hydroxide solution into the stirred mixed solution, continue to stir for 10min, seal the reaction bottle and place it in a 55°C oil bath, Take it out after reacting for 15 hours, and when the reaction bottle is cooled to room temperature, you can see a green and black precipitate at the bottom of the bottle, filter it with suction, wash it with deionized wat...

Embodiment 3

[0043] (1) Weigh 35.6 mg of carbon nanotubes modified with oxygen-containing functional groups, dissolve them in 30 mL of deionized water, and disperse them by ultrasonication for 20 min to 120 min.

[0044] (2) Weigh 213.9mg of nickel chloride, 142.8mg of cobalt chloride and 427.9mg of ammonium chloride respectively, dissolve them in the carbon nanotube solution in (1), and after mixing evenly, carry out ultrasonic treatment on the mixed solution for 10min to 30min , and then continue to stir the solution rapidly.

[0045] (3) Weigh 110mg of sodium hydroxide, dissolve it in 10mL of deionized water, quickly pour the sodium hydroxide solution into the stirred mixed solution, continue to stir for 10min, seal the reaction bottle and place it in a 55°C oil bath, Take it out after reacting for 15 hours, and when the reaction bottle is cooled to room temperature, you can see a green and black precipitate at the bottom of the bottle, filter it with suction, wash it with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com