Method for efficiently and rapidly recovering nickel and phosphorus in chemical nickel-plating waste liquid

A technology of electroless nickel plating and recovery method, applied in chemical instruments and methods, nickel oxide/nickel hydroxide, inorganic chemistry, etc., can solve problems such as environmental protection problems that cannot be solved, no research reports, etc., and achieve excellent electrocatalytic oxidation performance , The process is simple and reliable, and the effect of good environmental protection significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

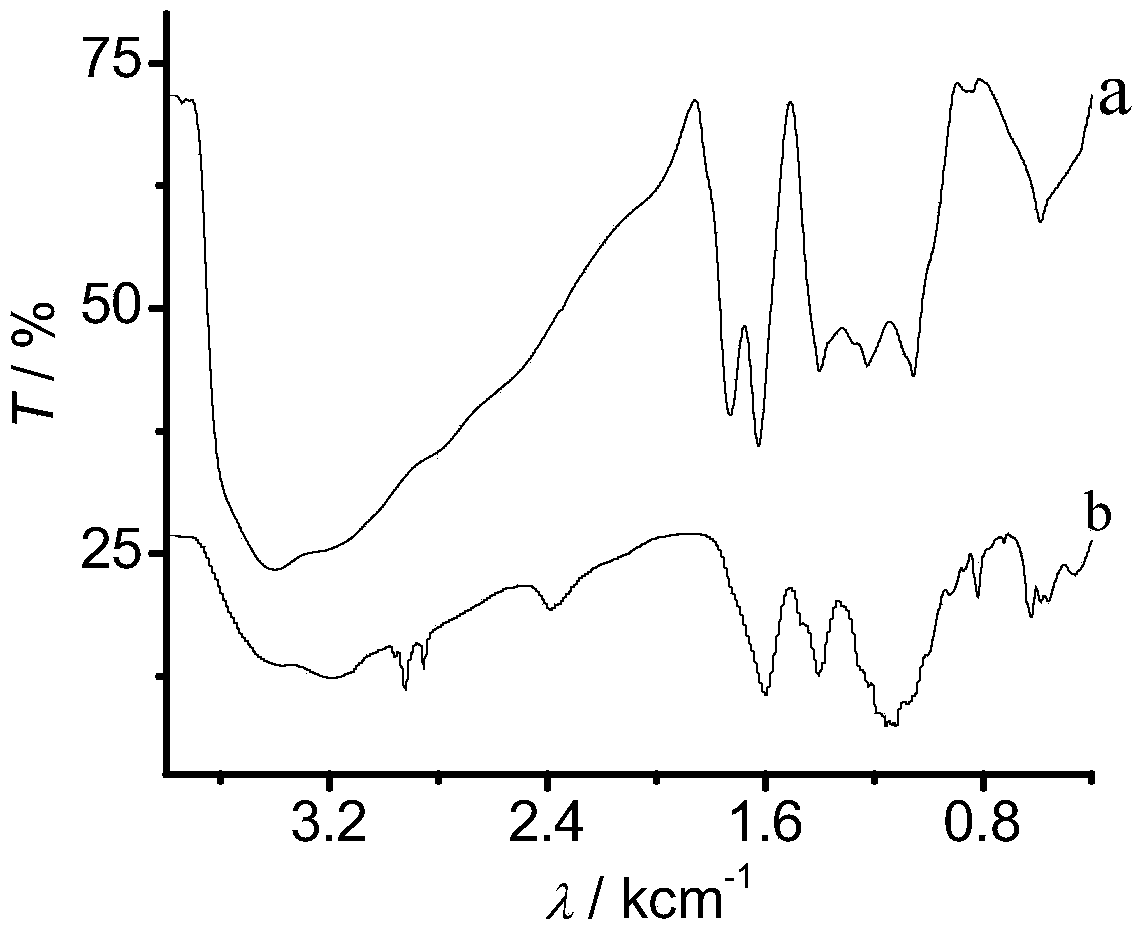

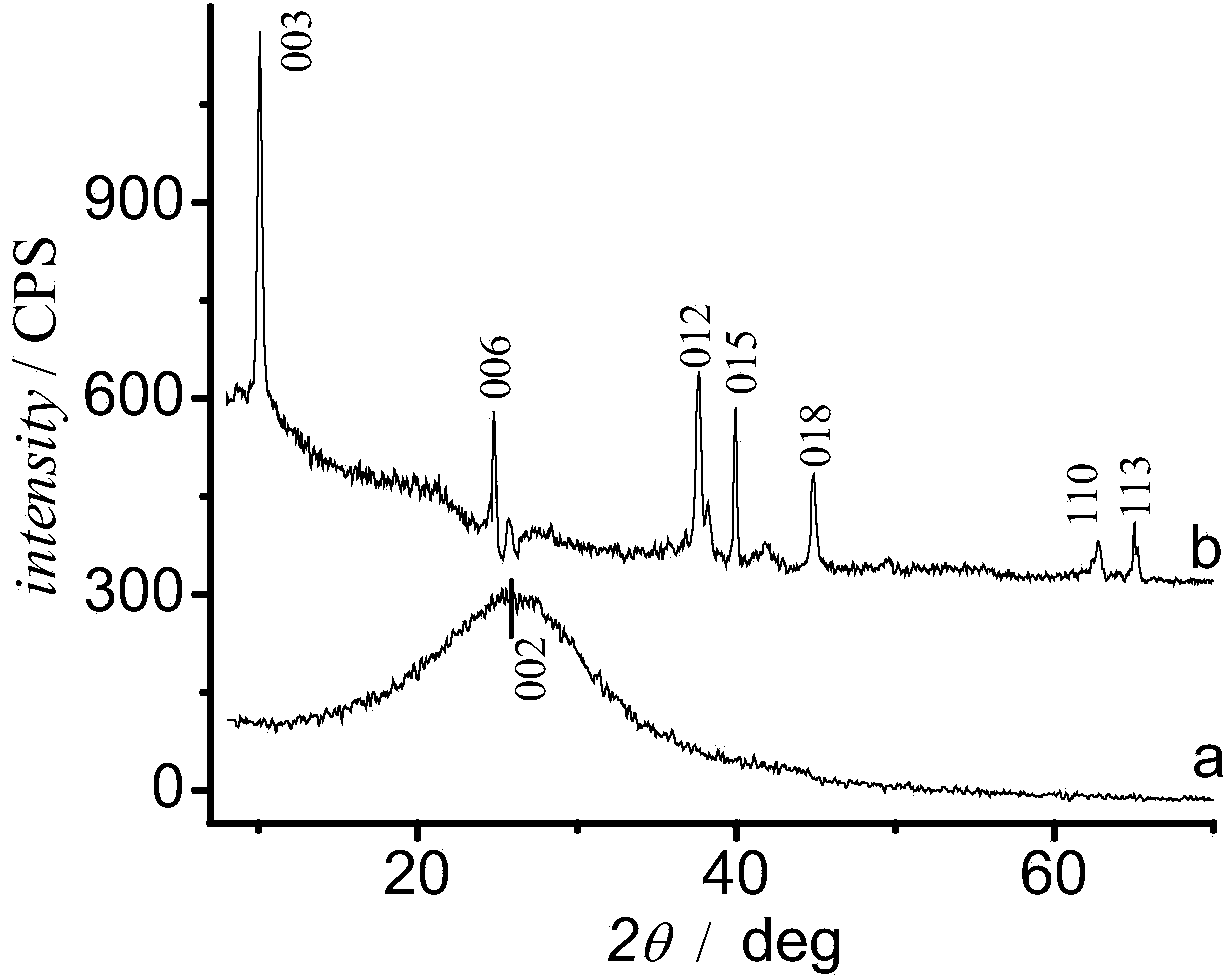

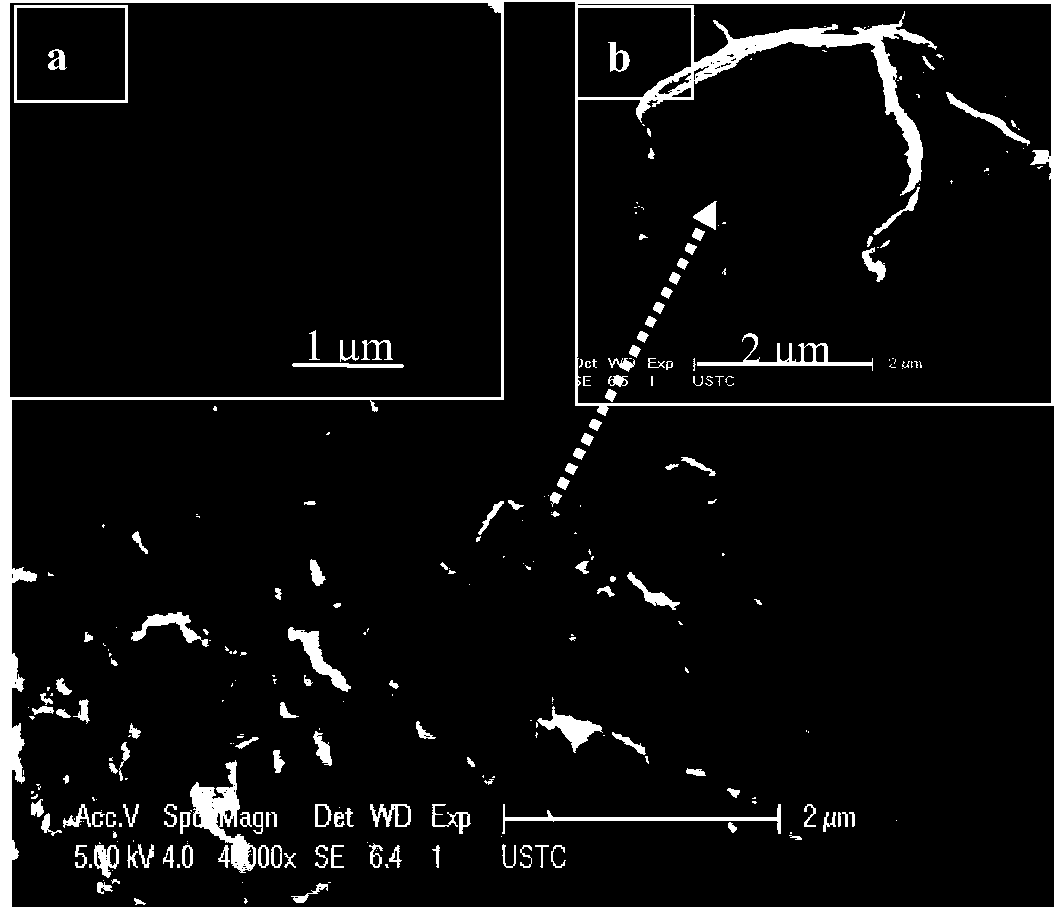

[0036] Add 3mL of hydrogen peroxide solution (30wt%) to 40mL of electroless nickel plating waste solution, stir for 30min, then add 0.22g of aluminum trichloride and 2mL of graphene oxide sheet suspension with a concentration of 10mg / L, and adjust the pH of the solution with NaOH The value is 8. It was synthesized ultrasonically in a nitrogen atmosphere for 20 minutes with an ultrasonic power of 40W, and then crystallized at 100°C for 5 hours. Take out and cool to room temperature, centrifuge, wash, and vacuum dry at 50 °C for 10 h to obtain GO / NiAl-LDHs composites.

[0037] The electroless nickel plating waste solution is NiSO 4 、Na 2 SO 4 , NaH 2 PO 2 , Lactic acid, H 2 SO 4 and Na 2 HPO 3 A mixed solution in which NiSO 4 The concentration is 0.107mol / L, Na 2 SO 4 The concentration is 0.35mol / L, NaH 2 PO 2The concentration of Lactic acid is 0.24mol / L, the concentration of Lactic acid is 0.30mol / L, the concentration of H 2 SO 4 The concentration is 0.20mol / L, N...

Embodiment 2

[0039] Add 0.30g of aluminum sulfate, 1mL of graphene oxide flake suspension with a concentration of 10mg / L and 5.2g of sodium peroxide to 40mL of electroless nickel plating waste liquid, adjust the pH value of the solution to 6 with NaOH, and ultrasonically synthesize it in a nitrogen atmosphere for 50min , ultrasonic power 60W, and then crystallized at 60°C for 2h. Take out and cool to room temperature, centrifuge, wash, and vacuum dry at 80°C for 6h to obtain GO / NiAl-LDHs composite material.

[0040] The electroless nickel plating waste solution is NiSO 4 、Na 2 SO 4 , NaH 2 PO 2 , Lactic acid, H 2 SO 4 and Na 2 HPO 3 A mixed solution in which NiSO 4 The concentration is 0.50mol / L, Na 2 SO 4 The concentration is 0.25mol / L, NaH 2 PO 2 The concentration of Lactic acid is 0.36mol / L, the concentration of Lactic acid is 0.30mol / L, H 2 SO 4 The concentration is 0.30mol / L, Na 2 HPO 3 The concentration is 0.30mol / L. The pH value of the waste electroless nickel plat...

Embodiment 3

[0042] Add 0.38g of aluminum phosphate, 0.6mL of graphene oxide layer suspension with a concentration of 10mg / L and 2.2g of potassium permanganate to 40mL of electroless nickel plating waste liquid, adjust the pH value of the solution to 11 with NaOH, and ultrasonically The synthesis was carried out for 40 minutes, the ultrasonic power was 100 W, and then crystallized at 60° C. for 4 hours. Take out and cool to room temperature, centrifuge, wash, and vacuum dry at 90°C for 5h to obtain GO / NiAl-LDHs composite material.

[0043] The electroless nickel plating waste solution is NiSO 4 、Na 2 SO 4 , NaH 2 PO 2 , Lactic acid, H 2 SO 4 and Na 2 HPO 3 A mixed solution in which NiSO 4 The concentration is 0.80mol / L, Na 2 SO 4 The concentration is 0.35mol / L, NaH 2 PO 2 The concentration of Lactic acid is 0.30mol / L, the concentration of Lactic acid is 0.50mol / L, H 2 SO 4 The concentration is 0.10mol / L, Na 2 HPO 3 The concentration is 0.20mol / L. The pH value of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com