Charcoal-based hard foamy carbon, preparation method thereof, and application of charcoal-based hard foamy carbon in electro-catalysis

A technology of rigid foam and biochar, applied in carbon preparation/purification, electrodes, electrolytic components, etc., can solve the problems of high cost of noble metal catalysts, low cycle life, high catalytic cost, etc., and achieve excellent electrocatalytic oxidation performance , high current density and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of biochar-based rigid foam carbon, comprising the following steps:

[0035] S1. Provide chitosan airgel;

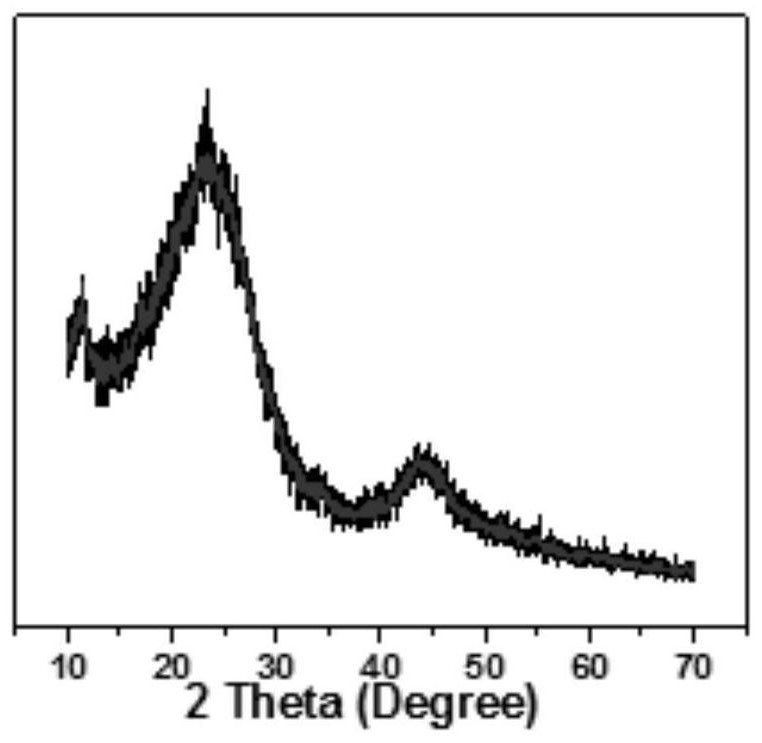

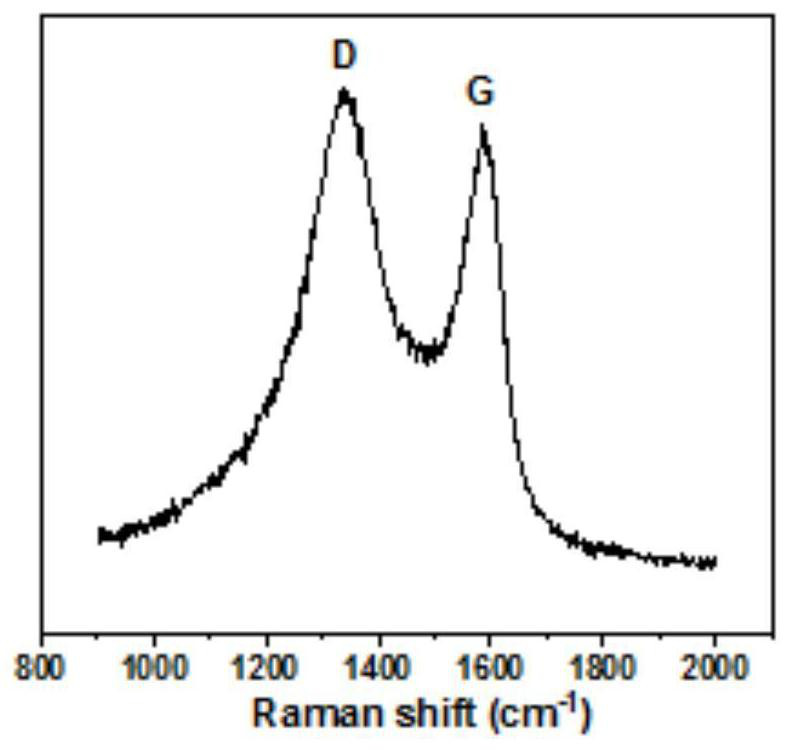

[0036] S2. Composite the chitosan airgel with a phenolic resin, and then perform pyrolysis in an inert gas atmosphere to obtain a biochar-based rigid foam carbon containing glassy carbon.

[0037] The rigid foam carbon prepared by the invention has a large specific surface area, high mechanical strength, good cycle life and practicability, can prepare electrode materials, and meets the requirements of low cost, easy preparation and high efficiency.

[0038] In the embodiment of the present invention, chitosan airgel is first prepared, and the raw material used is chitosan, which is prepared through sol-gel and freeze-drying to obtain a porous light solid material. Chitosan (chitosan) is the product of N-deacetylation of chitin, and its source is the shells of marine arthropods such as shrimps and crabs, the shel...

Embodiment 1

[0076] Synthesis of chitosan-resol phenolic resin pyrolytic foam carbon substrate:

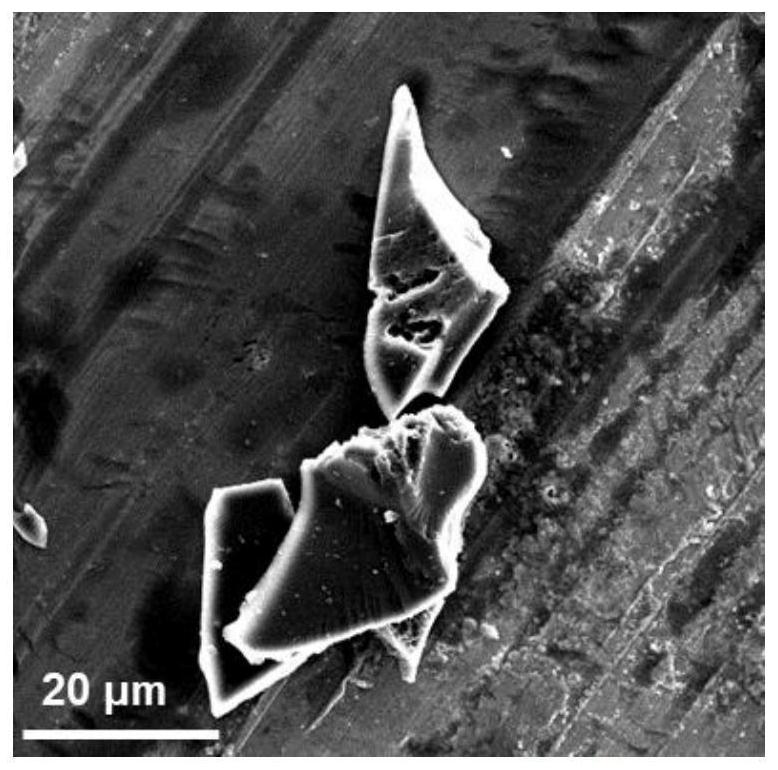

[0077] Disperse 3.3g chitosan powder in 50mL water, add a small amount of acetic acid dropwise while stirring to dissolve chitosan. The obtained chitosan gel was freeze-dried in a vacuum freeze dryer at -80° C. for 96 hours, and the obtained lightweight chitosan airgel was cut into blocks of 2 cm×2 cm×1 cm. Take 2.2g resorol, 3g formaldehyde solution and 5mg sodium carbonate, dissolve in 2mL water and mix ultrasonically for 10min, and add dropwise on the chitosan airgel block, so that it is completely saturated by the solution. The soaked chitosan block was placed in a sealed environment and heated at 70°C for 36h, and then transferred to a ventilated environment to continue drying and heating at 70°C for 12h. Afterwards, it was raised to 950°C under nitrogen atmosphere at 2.5°C / min under temperature control, and maintained for 6h; the pyrolyzed chitosan carbon block was ultrasonicated in dei...

Embodiment 2

[0088] Loading of hydrotalcite-based catalytically active components:

[0089] Take 60mg FeCl 2 ·5H 2 O, 262mg Ni(NO 3 ) 2 ·6H 2 O was dissolved in 30 mL of deionized water, and 90 mg of triethanolamine and 0.36 g of urea were added at the same time, and stirred evenly. Place the biochar-based rigid foam carbon substrate prepared in the preceding Example 1 in the 50mL stainless steel hydrothermal reactor In the inner lining, then slowly move the above mixed solution into the kettle, and place it in a blast oven at 120°C for hydrothermal treatment for 12 hours. After the hydrothermal heat was over, the reactor was taken out, placed in the air and slowly cooled to room temperature. After cooling, the biochar-based rigid foam carbon electrode in the reactor was taken out, and the precipitate attached to the surface was washed with deionized water three times, each time for 10 s. After rinsing, it was dried in the shade to obtain the prepared biochar-based rigid foam carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com