Preparation method of graphene

A technology of graphene and graphite electrodes, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of inability to synthesize graphene, complex process, high cost, etc., achieve the effect of low equipment requirements, simple production process, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

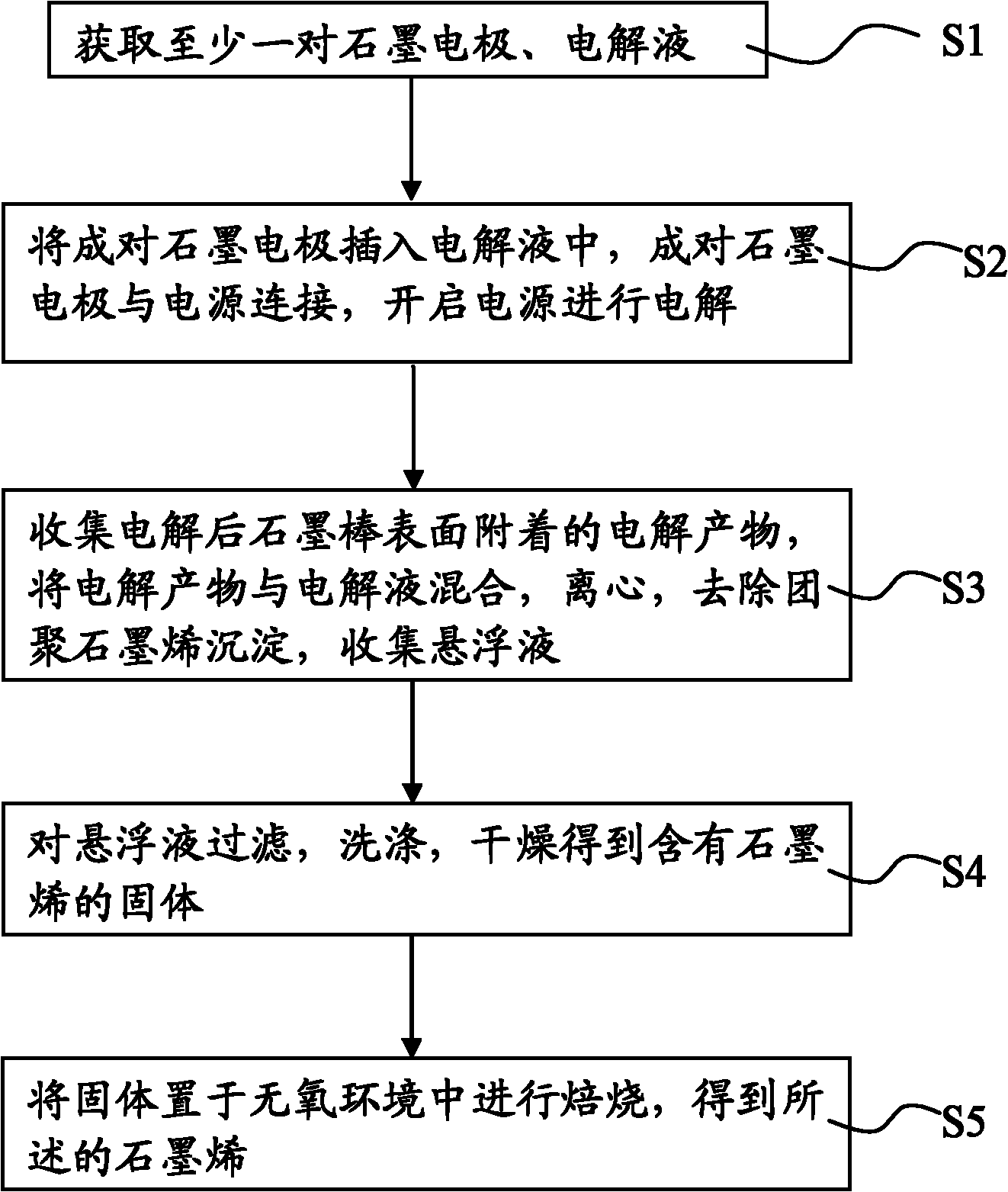

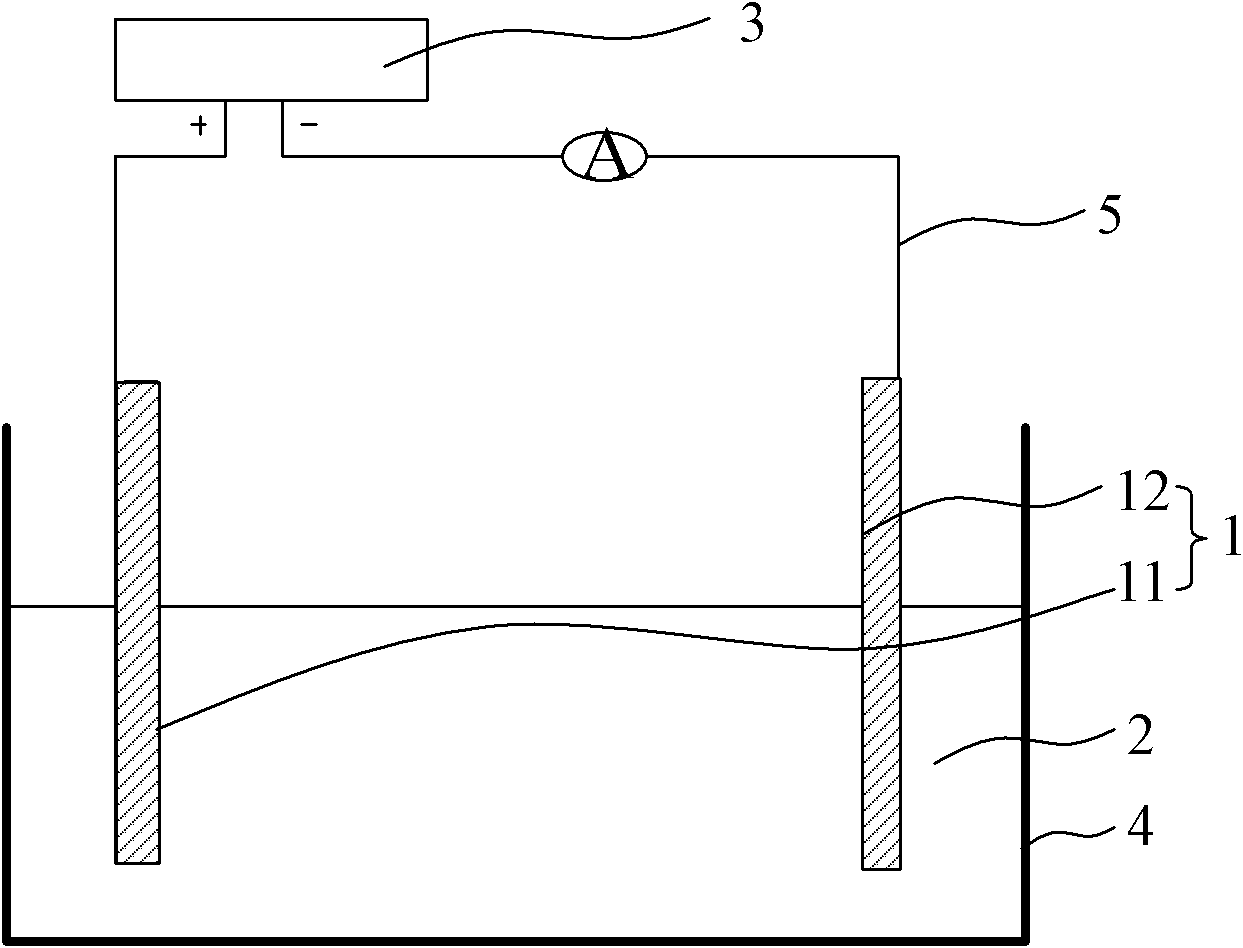

[0020] The embodiment of the present invention provides a graphene preparation method with simple production process, economical and environmental protection, and high product purity. The production process schematic diagram of this graphene preparation method is as figure 1 shown, also refer to figure 2 , the method comprises the following process steps:

[0021] S1: Obtain at least one pair of graphite electrodes 1, electrolyte 2, and power supply 3;

[0022] S2: Insert the paired graphite electrodes into the electrolyte 2, one graphite electrode 11 of the paired graphite electrodes 1 is connected to the positive pole of the power supply, and the other graphite electrode 12 is connected to the positive pole of the power supply. Negative connection, after the connection is complete, turn on the power switch for electrolysis;

[0023] S3: Collect the electrolysis product attached to the surface of the graphite electrode 1 after the electrolysis, mix the electrolysis produc...

Embodiment 1

[0036] A large amount of high-purity graphene preparation method technological process is as figure 1 Shown:

[0037] S1: Obtain a pair of graphite rods with a purity of 99.9%, an electrolyte, and a power supply with a voltage of 1.8V; the electrolyte is an aqueous solution of ammonium nitrate with a volume concentration of 35%;

[0038] S2: Insert the above-mentioned pair of graphite rods into the electrolyte, one graphite rod in the pair of graphite rods is connected to the positive pole of the power supply, and the other graphite rod is connected to the negative pole of the power supply. After the connection is completed, turn on the power switch to proceed Electrolysis 8h;

[0039] S3: Collect the electrolysis product attached to the surface of the graphite rod after electrolysis, mix the electrolysis product with the electrolyte, and then centrifuge at 1000rpm for 10 minutes to remove the agglomerated graphene precipitate and collect the suspension;

[0040] S4: filter ...

Embodiment 2

[0044] A large amount of high-purity graphene preparation method technological process is as figure 1 Shown:

[0045] S1: Obtain a pair of graphite rods with a purity of 99.9%, an electrolyte, and a power supply with a voltage of 2.5V; the electrolyte is an aqueous solution of ammonium nitrate with a volume concentration of 40%;

[0046] S2: Insert the above-mentioned pair of graphite rods into the electrolyte, one graphite rod in the pair of graphite rods is connected to the positive pole of the power supply, and the other graphite rod is connected to the negative pole of the power supply. After the connection is completed, turn on the power switch to proceed Electrolysis 6h;

[0047] S3: Collect the electrolysis product attached to the surface of the graphite rod after electrolysis, mix the electrolysis product with the electrolyte, and then centrifuge at 600rpm for 20 minutes to remove the agglomerated graphene precipitate and collect the suspension;

[0048] S4: filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com