Method for preparing high-quality single/double-layer controllable molybdenum disulfide

A molybdenum disulfide, double-layer technology, applied in the field of two-dimensional molybdenum disulfide preparation, can solve the problems of poor controllability, harsh preparation conditions, and repeatability to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

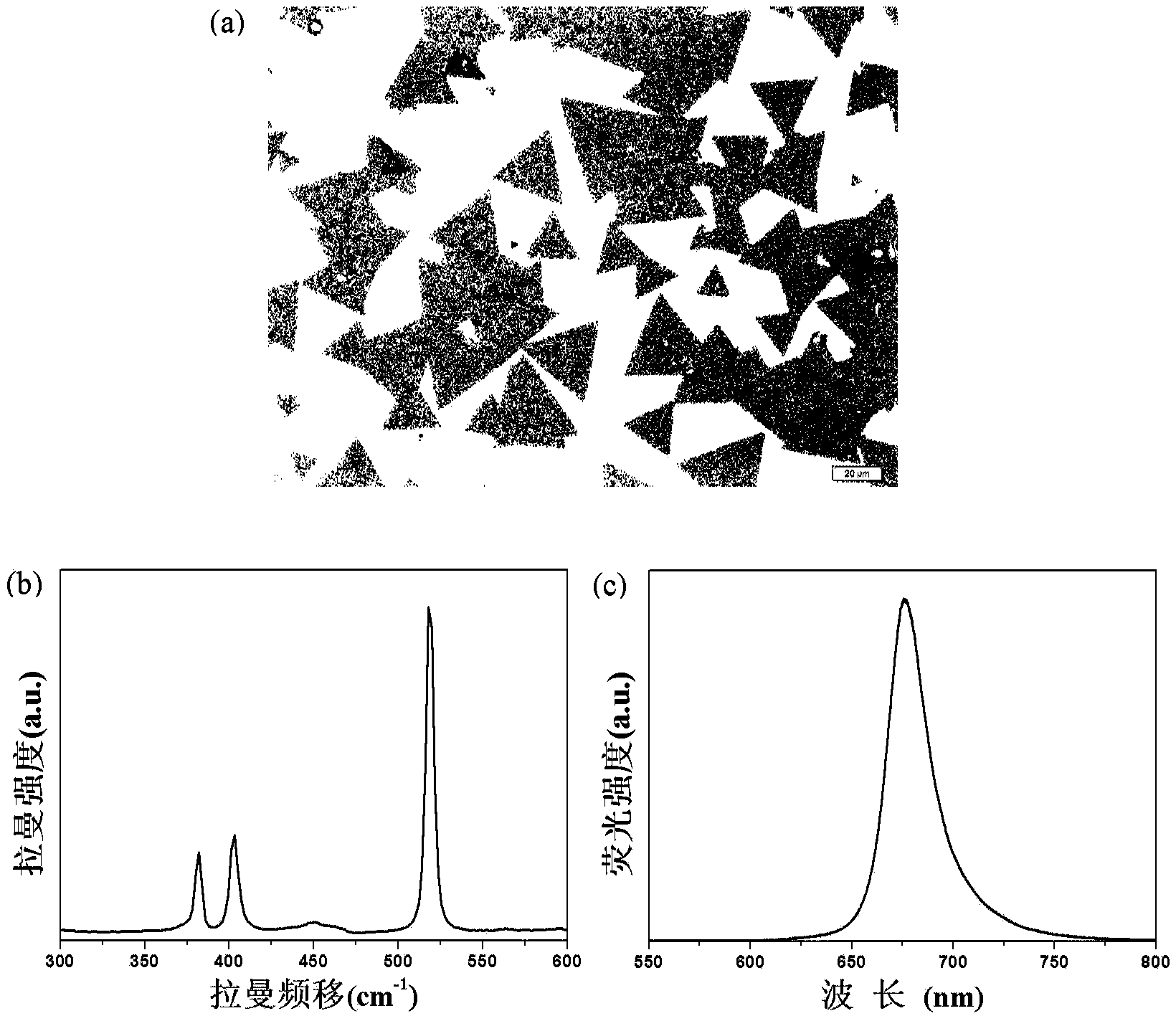

Embodiment 1

[0034] The surface will contain about 250nm thick SiO 2 Put the Si sheet of the first layer into a mixture of alcohol and acetone and ultrasonically clean it for 5 minutes, then clean it with a deionized water solution, and dry it with nitrogen;

[0035] Cut molybdenum sheets with a purity of 99.99% into strips of 3×5 mm, put them in a mixture of alcohol and acetone and ultrasonically clean them for 5 minutes, then clean them with deionized water and dry them with nitrogen;

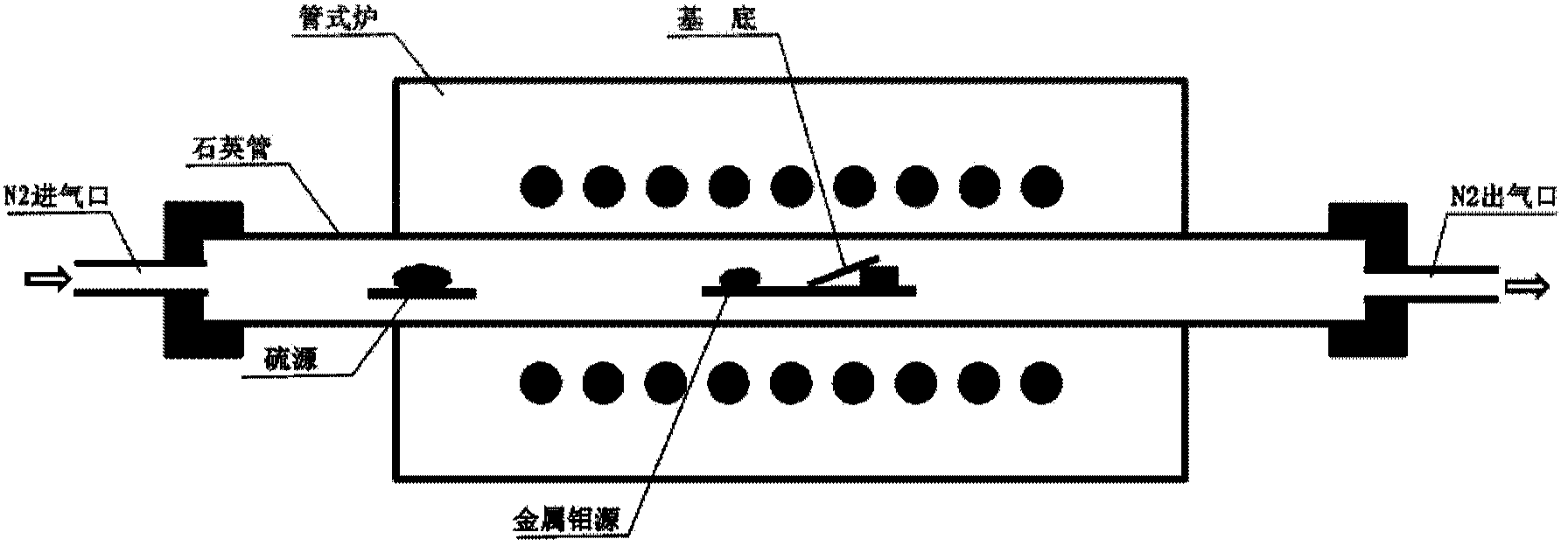

[0036] The dried SiO 2 The / Si sheet and the strip-shaped molybdenum sheet are put into the ceramic boat at the same time, and the distance between the two is 2cm. Push the ceramic boat into the high temperature zone of the quartz tube of the tube furnace, wherein the outer diameter of the quartz tube is 60mm and the inner diameter is 54mm.

[0037] The sulfur powder that is 99.5% and the quality is put into a new ceramic boat with a purity of 99.5%, and the ceramic boat is placed in the low temperature...

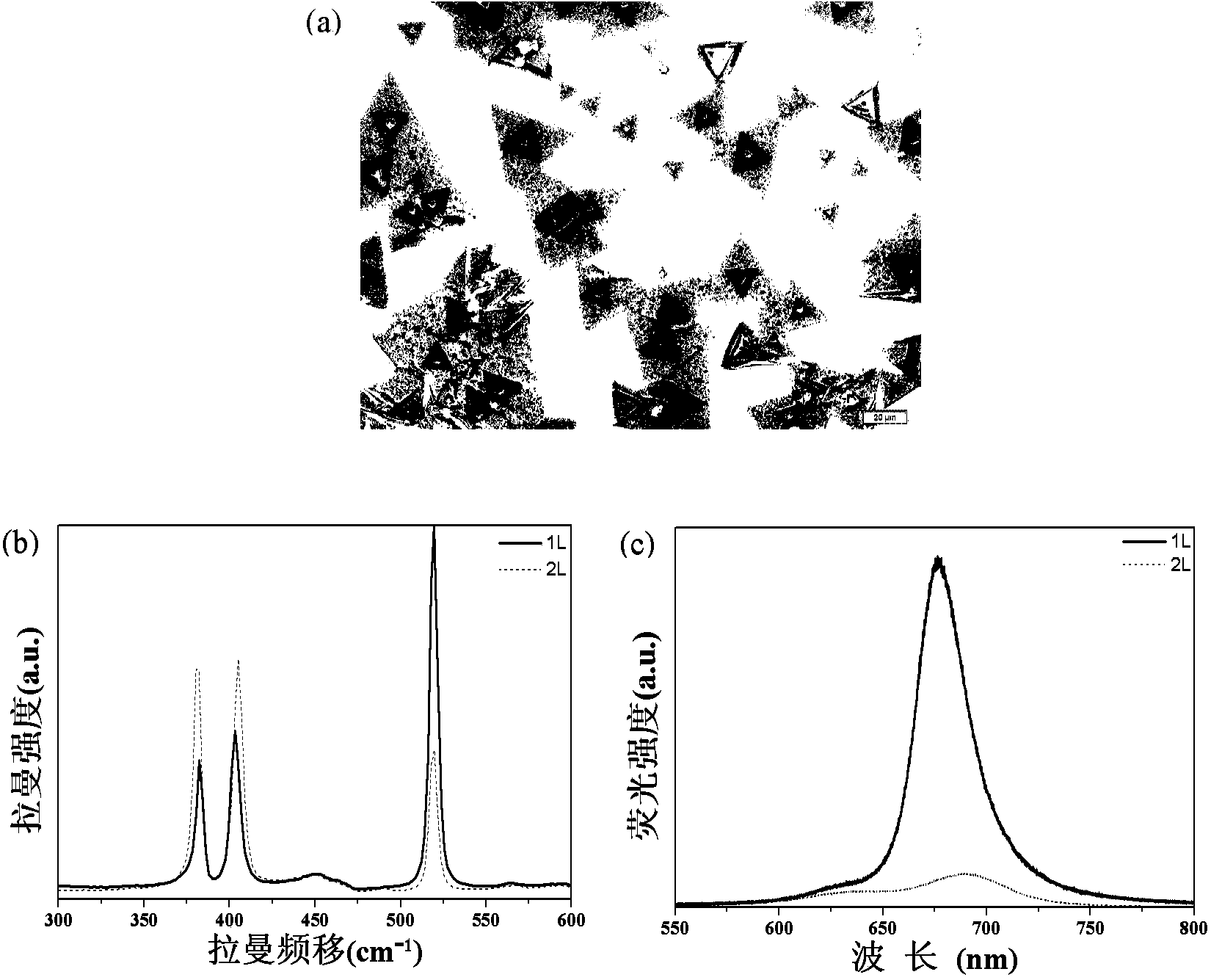

Embodiment 2

[0043] Surface containing 250nm thick SiO 2 Put the Si sheet of the first layer into a mixture of alcohol and acetone and ultrasonically clean it for 5 minutes, then clean it with a deionized water solution, and dry it with nitrogen;

[0044] Cut molybdenum sheets with a purity of 99.99% into strips of 3×5 mm, put them in a mixture of alcohol and acetone and ultrasonically clean them for 5 minutes, then clean them with deionized water and dry them with nitrogen;

[0045] The dried SiO 2 The / Si sheet and the strip-shaped molybdenum sheet are put into the ceramic boat at the same time, and the distance between the two is 2cm. Push the ceramic boat into the high temperature zone of the quartz tube of the tube furnace, wherein the outer diameter of the quartz tube is 60mm and the inner diameter is 54mm.

[0046] The sulfur powder that is 99.5% and the quality is put into a new ceramic boat with a purity of 99.5%, and the ceramic boat is placed in the low temperature zone of the...

Embodiment 3

[0052] The surface will contain about 250nm thick SiO 2 Put the Si sheet of the first layer into a mixture of alcohol and acetone and ultrasonically clean it for 5 minutes, then clean it with a deionized water solution, and dry it with nitrogen;

[0053] Cut molybdenum sheets with a purity of 99.99% into strips of 3×5 mm, put them in a mixture of alcohol and acetone and ultrasonically clean them for 5 minutes, then clean them with deionized water and dry them with nitrogen;

[0054] The dried SiO 2 The / Si sheet and the strip-shaped molybdenum sheet are put into the ceramic boat at the same time, and the distance between the two is 2cm. Push the ceramic boat into the high temperature zone of the quartz tube of the tube furnace, wherein the outer diameter of the quartz tube is 60mm and the inner diameter is 54mm.

[0055] The sulfur powder that is 99.5% and the quality is put into a new ceramic boat with a purity of 99.5%, and the ceramic boat is placed in the low temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com