Method for pretreating fibers

A pretreatment and fiber technology, applied in fiber treatment, textiles and papermaking, etc., can solve problems such as fiber damage, and achieve the effect of low cost, low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

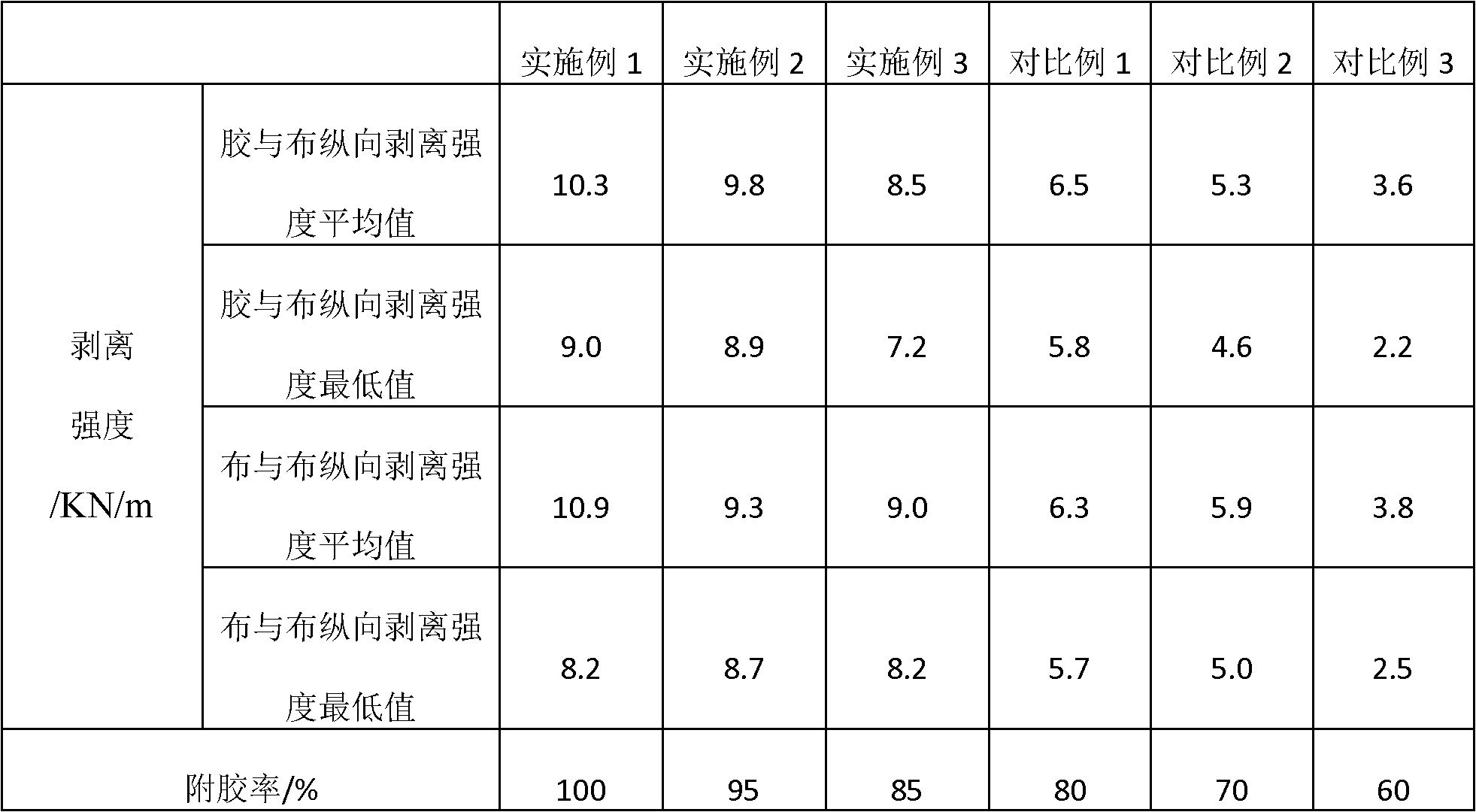

Examples

Embodiment 1

[0026] Surface activation: configure 1L of 1g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.5 with tris (commercially available), put 10cm*10cm polyester canvas (commercially available) into the solution, , aerobic, and stirred for 2 hours, weighed 25g of water-soluble epoxy resin (commercially available) and added it to the reaction solution to continue the reaction for 8 hours, then took out the polyester canvas and washed it with water.

[0027] Dipping treatment: Add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 40°C for 4 hours to obtain a phenolic resin solution. Add styrene-butadiene latex to the phenolic resin solution and stir well. Stand at room temperature for 16 hours to obtain a dipping solution. The mass percent content of each component is: 1.86% of resorcinol, 1% of formaldehyde, 0.05% of sodium hydroxide, 41.20% of styrene-butadiene latex, and 64.19% of water. After imm...

Embodiment 2

[0038] Surface activation: configure 1L of 2g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.0 with tris (commercially available), put 10cm*10cm aramid canvas (commercially available) into the solution, , aerobic, and stirred for 2 hours, weighed 50 g of silane coupling agent Si69 and added it to the reaction solution to continue the reaction for 12 hours, then took out the aramid canvas and washed it with water to dry it.

[0039] Dipping treatment: Add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 30°C for 6 hours to obtain a phenolic resin solution. Add styrene-butadiene latex to the phenolic resin solution and stir well. Stand at room temperature for 18 hours to obtain a dipping solution. The mass percent content of each component is: 2.03% of resorcinol, 1.20% of formaldehyde, 0.06% of sodium hydroxide, 34.71% of styrene-butadiene latex, and 62.00% of water. After immersing the surf...

Embodiment 3

[0042] Surface activation: configure 1L of 4g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.3 with tris (commercially available), put 10cm*10cm ultra-high molecular weight polyethylene canvas (commercially available) into the solution , reacted at room temperature, aerobic, and stirred for 2h, weighed 75g of GMA (glycidyl methacrylate, commercially available) and added it to the reaction solution to continue the reaction for 20h, then took out the ultra-high molecular weight polyethylene canvas and washed it with water.

[0043] Dipping treatment: Add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 25°C for 6 hours to obtain a phenolic resin solution. Add vinylpyridine latex to the phenolic resin solution and stir well. Stand at room temperature for 20 hours to obtain a dipping solution. The mass percent content of each component is: water 60.07%, resorcinol 1.93%, formaldehyde 1.03%, sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com