Preparation method of fiber felt enhanced silica aerogel composite panel

A technology of silica and fiber felt, which is applied in the field of fire prevention, sound insulation materials, oil pollution adsorption, and building thermal insulation. The effect of low strength and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

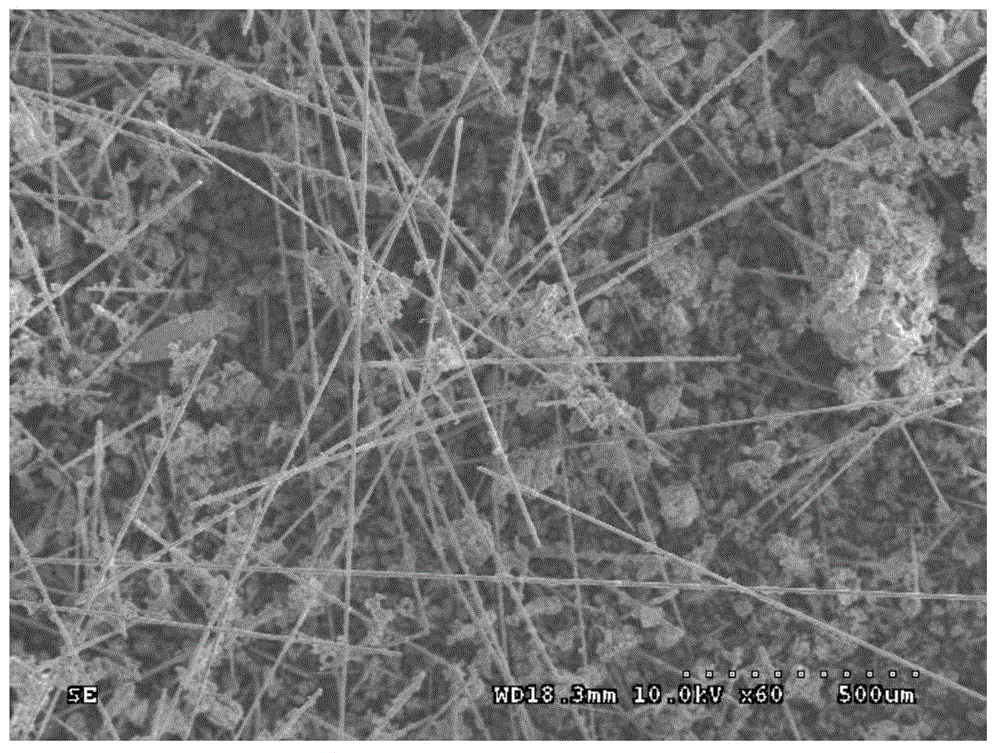

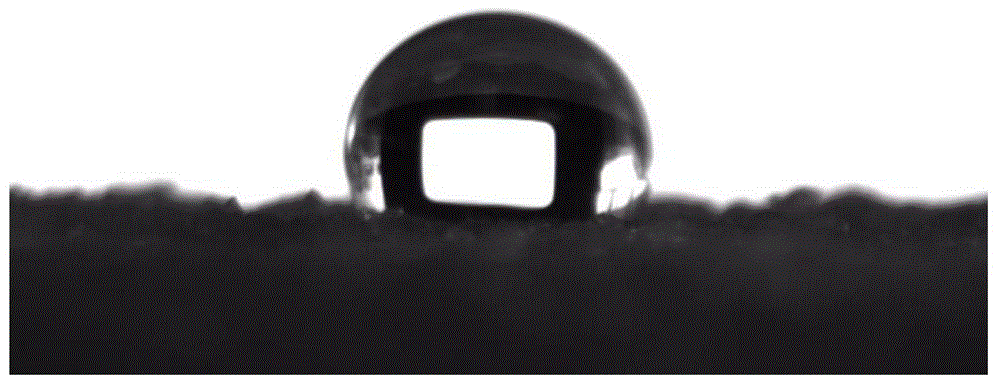

[0032] The water glass (modulus: 3.1 Baume 40), absolute ethanol, deionized water, and hydrofluoric acid are uniformly mixed and reacted at a volume ratio of 1:2:6:0.03 for 5 hours to obtain a silicone gel. The silicone gel is immersed in the trimethylchlorosilane / n-hexane solution, the volume ratio of the trimethylchlorosilane, n-hexane and the silicone gel is 1:5:10, and it is modified at room temperature for 24h. The modified gel is dried and pulverized to obtain hydrophobic silica aerogel particles with an average particle diameter of 0.2 mm. Take the silica aerogel particles, EVA powder and n-hexane solution in a volume ratio of 1:0.05:10 to blend into a mixed solution. After stirring at 1200R / min for 0.1h, immerse the glass fiber mat in the mixed solution. The volume ratio of the glass fiber mat to the mixed solution is 1:5, while performing ultrasonic dispersion at a frequency of 60KHZ, take it out after 0.3h, and heat-press at 120℃, 0.2MP for 15min, cool to room tempera...

example 2

[0034] Mix water glass (modulus of 2.5 Baume 39), absolute ethanol, deionized water, and hydrofluoric acid in a volume ratio of 1:4:3:0.07 at room temperature for 8 hours, trimethylchlorosilane, n-hexane and The volume ratio of silica gel is 1:10:15, and the volume ratio of silica aerogel particles, EVA powder and n-hexane solution is 1:0.15:15. Alumina fiber felt is used as a reinforcing matrix. Alumina fiber felt The volume ratio to the mixed solution is 1:5, 80HZ ultrasonic dispersion for 40min, and hot pressing for 50min under the conditions of 80℃ and 1MP. Other conditions were the same as in Example 1, and a composite board of silica aerogel and alumina fiber felt was prepared.

example 3

[0036] Mix water glass (modulus of 3.4 Baume 46), absolute ethanol, deionized water, and hydrofluoric acid in a volume ratio of 1:3.5:5:0.05 at room temperature for 6h, and use hexamethyldisilane / n-hexane Alkane is used as the modifier, and the volume ratio of hexamethyldisilane, n-hexane and silica gel is 1:5:15. The silica aerogel prepared by the modification at room temperature for 48 hours is dried under normal pressure and crushed. Prepare silica aerogel powder with an average particle size of 0.25mm, blend the silica aerogel particles, EAA powder and n-hexane solution in a volume ratio of 1:0.1:15, and stir at a high speed of 2000R / min for 0.1h Then, immerse the boron oxide fiber felt in the mixed solution, the volume ratio of the boron oxide fiber felt to the mixed solution is 1:3, and perform ultrasonic dispersion at a frequency of 40KHZ, take it out after 1h, and heat press for 30min at 80℃ and 0.7MP. , Cooling to normal temperature and maintaining the pressure for 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com