Preparation method of hydrophobic silica aerogel composite fiber felt material

A composite fiber mat and silica technology are applied in the fields of environment-friendly ceramic fiber mat, glass fiber mat reinforced silica aerogel composite material preparation, and hydrophobic silica aerogel composite fiber mat material preparation field, It can solve the problems of high brittleness, difficult industrial application and low aerogel strength, and achieve the effects of low density, mild modification conditions and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

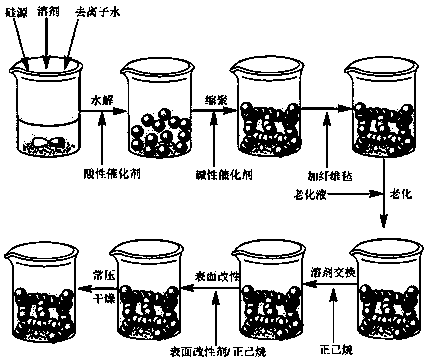

[0037] Embodiment 1 of the present invention The preparation method of hydrophobic silica airgel composite fiber felt comprises the following steps:

[0038] (1) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the container, and mix and stir for 5 minutes according to molar ratio, tetraethyl orthosilicate: absolute ethanol: deionized water at 1:7:3; Add 1 mol / L hydrochloric acid, adjust the pH to 2-3, stir and hydrolyze for 1.5 hours to obtain silica sol;

[0039] (2) Add 0.446mol / L ammonia water to the above-mentioned silica sol, slowly add drop by drop and stir while adding, adjust the pH to about 7, then quickly pour it into ceramic and glass fiber mat prefabricated parts , and ensure that the surface is free of air bubbles and smooth until it is just submerged in the fiber mat, let it stand, and wait for the sol to gel in the fiber mat;

[0040] (3) Put the gelled composite material in a plastic or glass container, add tetraethyl orthosilicate: anh...

Embodiment 2

[0052] Embodiment 2 of the present invention The preparation method of the hydrophobic silica airgel composite fiber mat comprises the following steps:

[0053] (1) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the container, and mix and stir for 10 min according to molar ratio, tetraethyl orthosilicate: absolute ethanol: deionized water at 1:5:1; Add 1 mol / L hydrochloric acid, adjust the pH to 2-3, stir and hydrolyze for 12 hours to obtain silica sol;

[0054] (2) Add 0.5mol / L ammonia water to the above-mentioned silica sol, slowly add dropwise and stir while adding, adjust the pH to about 7, then quickly pour it into the prefabricated parts of ceramic and glass fiber mat , and ensure that the surface is free of air bubbles and smooth until it is just submerged in the fiber mat, let it stand, and wait for the sol to gel in the fiber mat;

[0055] (3) Put the gelled composite material in a plastic or glass container, add tetraethyl orthosilicate: anh...

Embodiment 3

[0061] Embodiment 3 of the present invention The preparation method of hydrophobic silica airgel composite fiber mat comprises the following steps:

[0062] (1) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the container, and mix and stir for 20 minutes according to the molar ratio of tetraethyl orthosilicate: absolute ethanol: deionized water at 1:7:3; Add 1 mol / L hydrochloric acid, adjust the pH to 2-3, stir and hydrolyze for 6 hours to obtain silica sol;

[0063] (2) Add 0.446mol / L ammonia water to the above-mentioned silica sol, slowly add it dropwise and stir while adding it, adjust the pH to about 7, then quickly introduce it into the ceramic and glass fiber mat prefabricated parts, And ensure that the surface is free of air bubbles and flat, until it just submerges the fiber mat, let it stand, and wait for the sol to gel in the fiber mat;

[0064] (3) Put the gelled composite material in a plastic or glass container, add tetraethyl orthosilica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com