Method for preparing hydrophobic SiO2 aerogel

An aerogel and hydrophobic technology, which is applied in the field of preparing hydrophobic SiO2 aerogels, can solve problems such as large-scale application constraints, aerogels affecting performance, and unsafety, and achieve easy-to-control reactions, high porosity, and hydrophobic good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

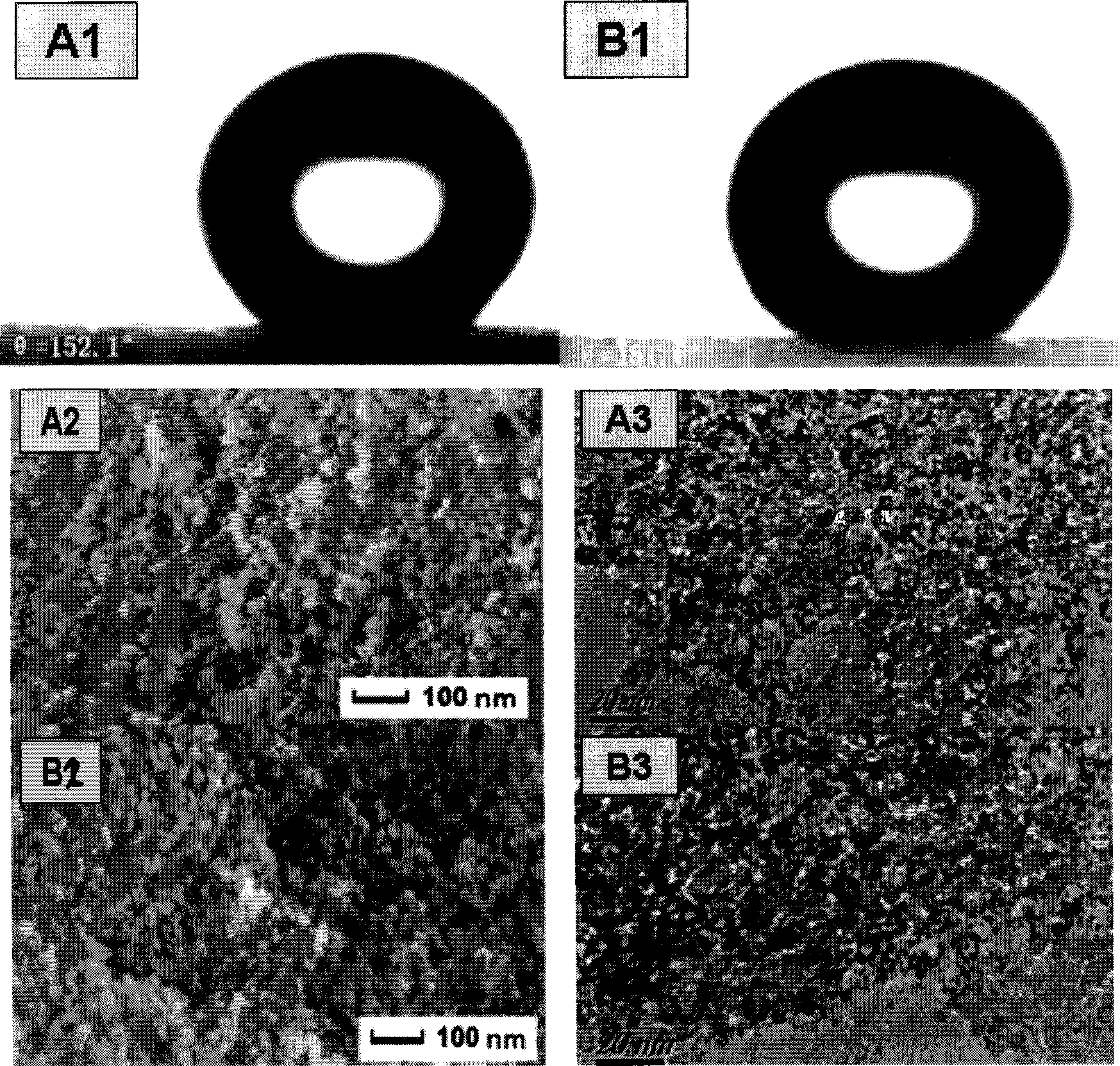

Image

Examples

example 1

[0026] Measure 16.1ml of tetraethyl orthosilicate, add it to 16.8ml of absolute ethanol, add dropwise 6.4ml of oxalic acid aqueous solution with a concentration of 0.008M to the above system under stirring, and wait until all the drops are finished, at room temperature After hydrolysis under stirring for 24 hours, 0.5 ml of ammonia water with a concentration of 0.5 M was added dropwise to the hydrolysis system, and gelation occurred after a few minutes to obtain 38 ml of silica wet gel.

[0027] The water in the wet gel was replaced with absolute ethanol 3 times within 32-40 hours, the volume ratio of absolute ethanol to gel was 2:1, and the replacement time was 10-15 hours each time.

[0028] Then use 76ml of n-hexane to replace ethanol three times within 32-40 hours. After the replacement is completed, add hexamethyldisilazane / n-hexane solution with a volume ratio of 1:4, and carry out 20 After ~28 hours of surface modification, the unreacted hexamethyldisilazane was replace...

example 2

[0032] Measure 16.1ml of tetraethyl orthosilicate, add it to 16.8ml of absolute ethanol, add dropwise 6.4ml of oxalic acid aqueous solution with a concentration of 0.006-0.01M to the above system under stirring, and wait until all the drops are finished, After hydrolysis at room temperature for 24 hours, 0.5 ml of ammonia water with a concentration of 0.5 M was added dropwise to the hydrolysis system, and gelation occurred after a few minutes to obtain 38 ml of silica wet gel.

[0033] The water in the wet gel was replaced with absolute ethanol 2-3 times within 36 hours, the volume ratio of absolute ethanol to gel was 2:1, and the replacement time was 10-15 hours each time.

[0034] Then use 76ml of n-hexane to replace ethanol 3 times within 32-40 hours. After the replacement is completed, add a dimethyldichlorosilane / n-hexane solution with a volume ratio of 1:4 to it, and carry out the process at an ambient temperature of 50-60°C. After 24 hours of surface modification, the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com