Superhydrophobic composite coating with self-repair function and preparation method thereof

A composite coating, super-hydrophobic technology, applied in coatings and other directions, can solve the problems of low mechanical strength of self-healing super-hydrophobic coatings, and achieve the effects of improving mechanical strength, increasing storage capacity, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

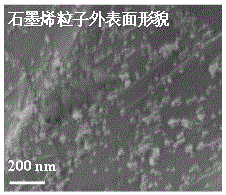

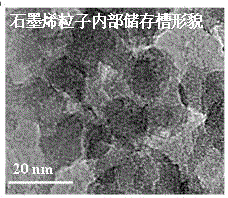

Image

Examples

Embodiment 1

[0034] (1) Metal substrate surface pretreatment:

[0035] Use sandpaper to quickly polish the surface of the aluminum substrate and put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. Use an ethanol solution with a mass concentration of 80%, take it out and dry it naturally, and save it for later use;

[0036] (2) Preparation of superhydrophobic and oleophobic emulsion:

[0037] 10 parts of ammonia water and 10 parts of graphene are uniformly dispersed in 100 parts of organic solvent, and 10 parts of tetraethylorthosilicate are added to the above-mentioned mixed solution of graphene and ammonia water at a rate of 0.1 mL / min to prepare a sol solution. Then add 90 parts of polyvinylidene fluoride (PVDF) and 3 parts of low surface energy modifier to carry out magnetic stirring. Finally, 7 parts of ammonium bisulfate dissolved in 15 parts of deionized water was mixed with the above solution at a dropping rate of 1 ...

Embodiment 2

[0052] (1) Surface pretreatment of metal pipelines:

[0053] The surface of the metal tube is treated by sandblasting, and then put into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. The concentration of the ethanol solution is 95%, take it out and dry it naturally;

[0054] (2) Preparation of superhydrophobic and oleophobic emulsion:

[0055] 12 parts of ammonia water and 15 parts of graphene were uniformly dispersed in 80 parts of ethanol solvent, and 12 parts of tetrabutyl titanate were added to the above mixed solution of graphene and ammonia water at a rate of 0.4 mL / min to prepare a sol solution . Add 75 parts of polyphenylene sulfide (PPS) and 4 parts of low surface energy modifier to carry out magnetic stirring. Finally, 5 parts of ammonium bicarbonate dissolved in 15 parts of deionized water was mixed with the above solution at a dropping rate of 1 mL / min to obtain a superhydrophobic coating emulsion. The op...

Embodiment 3

[0065] (1) Surface pretreatment of metal pipelines:

[0066] Use sandblasting to treat the surface of the metal pipeline, put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface, the concentration of the ethanol solution is 90%, take it out and dry it naturally, and save it for later use;

[0067] (2) Preparation of superhydrophobic and oleophobic emulsion: 20 parts of ammonia water and 20 parts of graphene were uniformly dispersed in 90 parts of ethanol solvent, and 20 parts of tetrabutyl titanate were added to the above graphene and In the mixed solution of ammonia water, a sol solution was prepared. Then add 40 parts of perfluorosiloxane resin, 45 parts of perfluoroethylene propylene copolymer (FEP) and 5 parts of low surface energy modifier to carry out magnetic stirring. Finally, 6 parts of ammonium carbonate dissolved in 20 parts of deionized water was mixed with the above solution at a dropping rate of 2 mL / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com