Mono-dispersed spherical mesoporous silicon dioxide nanomaterial and preparation method thereof

A technology of mesoporous silica and nanomaterials, applied in the field of inorganic porous materials, can solve the problems of poor mesoporous pore structure order, unsatisfactory particle size uniformity, etc., achieves good monodispersity, short preparation period, Particle size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 0.20 g of cetyltrimethylammonium bromide in 86.4 ml of deionized water, add 9.6 ml of ethanol and 0.7 ml of 2 mol / L sodium hydroxide to the deionized water, and stir vigorously at 80 ° C for 0.5 hours to The solution was clear and transparent, and then 1.15ml tetraethyl orthosilicate was added rapidly under stirring, and the vigorous stirring was continued at 80°C for 2 hours. The reaction mixture was successively filtered, washed with ethanol three times, dried under vacuum at 60°C for 12 hours, and calcined at 550°C in air for 5 hours to obtain monodisperse spherical mesoporous silica nanomaterials.

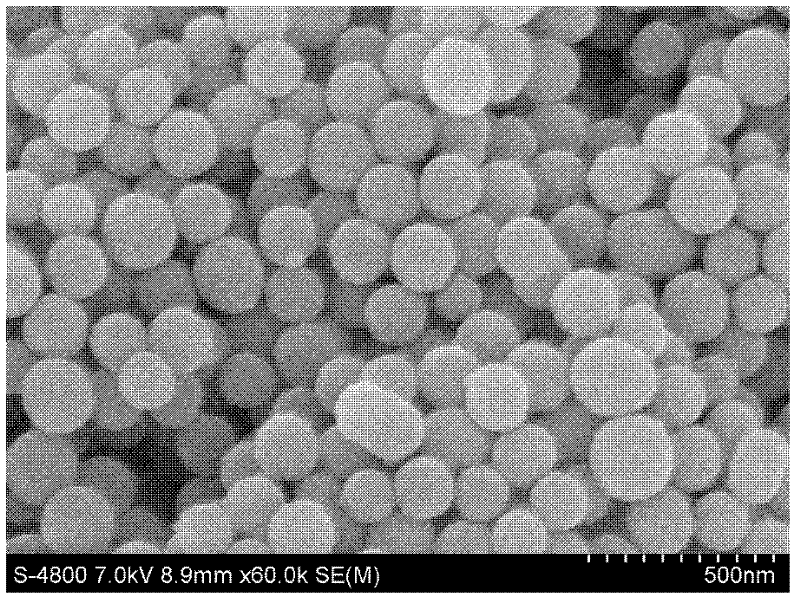

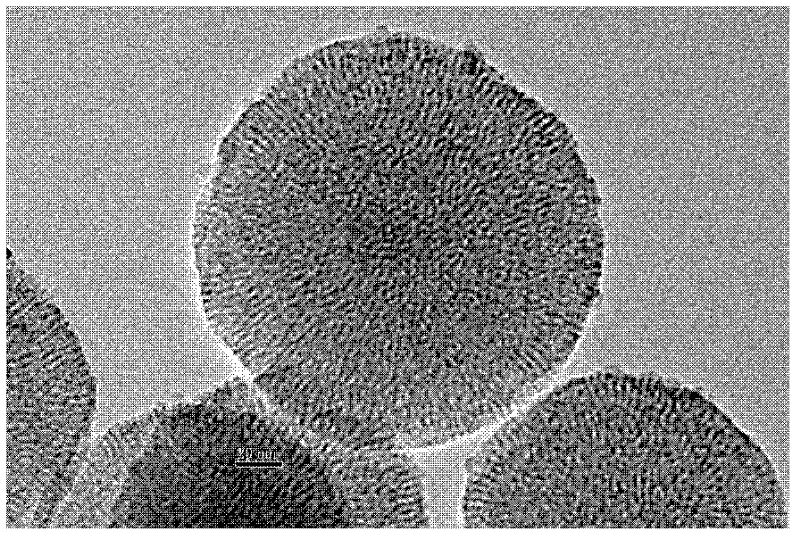

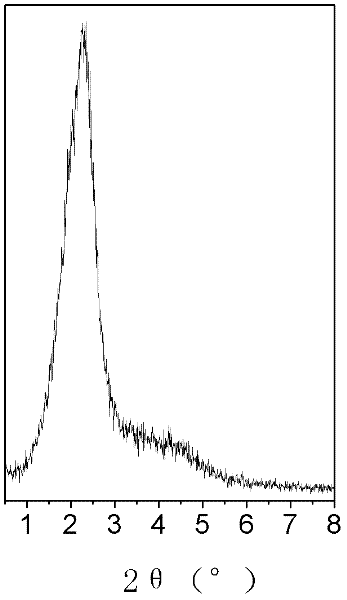

[0024] from figure 1 and figure 2 It can be seen that the morphology of the synthesized silica is spherical and has good monodispersity. The average particle diameter is 160nm, and the relative standard deviation of particle diameter is 4.87%. from figure 2 It can be seen that the material has a pore structure arranged radially from the center of the spher...

Embodiment 2

[0026] Dissolve 0.20g of cetyltrimethylammonium bromide in 96ml of deionized water, add 0.7ml of 2mol / L sodium hydroxide, stir vigorously at 80°C for 0.5 hours until the solution is clear and transparent, then quickly add 1.15ml of tetraethyl orthosilicate, and continue to stir vigorously at 80°C for 2 hours. The reaction mixture was filtered, washed three times with ethanol, dried at 60°C for 12 hours in a vacuum environment, and calcined at 550°C for 5 hours in an air environment to obtain monodisperse spherical mesoporous silica nanomaterials.

[0027] The average particle size of the obtained monodisperse spherical mesoporous silica nanomaterial is 80nm, the relative standard deviation of particle size is 6.37%, the interplanar distance is 3.77nm, the mesoporous aperture is 2.55nm, and the specific surface area is 1057m 2 / g, the pore volume is 0.74cm 3 / g.

Embodiment 3

[0029] Dissolve 0.20 g of cetyltrimethylammonium bromide in 86.4 ml of deionized water, add 9.6 ml of ethanol and 0.7 ml of 2 mol / L sodium hydroxide to the deionized water, and stir vigorously at 80 ° C for 0.5 hours to The solution was clear and transparent, and then 0.75ml tetraethylorthosilicate was added rapidly under stirring, and the vigorous stirring was continued at 80°C for 2 hours. The reaction mixture was filtered, washed three times with ethanol, dried at 60°C for 12 hours in a vacuum environment, and calcined at 550°C for 5 hours in an air environment to obtain monodisperse spherical mesoporous silica nanomaterials.

[0030] The average particle size of the obtained monodisperse spherical mesoporous silica nanomaterial is 150nm, the relative standard deviation of the particle size is 7.40%, the interplanar spacing is 3.62nm, the mesoporous aperture is 2.51nm, and the specific surface area is 1367m 2 / g, the pore volume is 0.83cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com