Process for preparing silica microcapsules

a technology of silica and microcapsules, applied in the field of process for preparing silica microcapsules, can solve the problems of skin troubles, deterioration of cosmetics quality, poor chemical stability properties, etc., and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

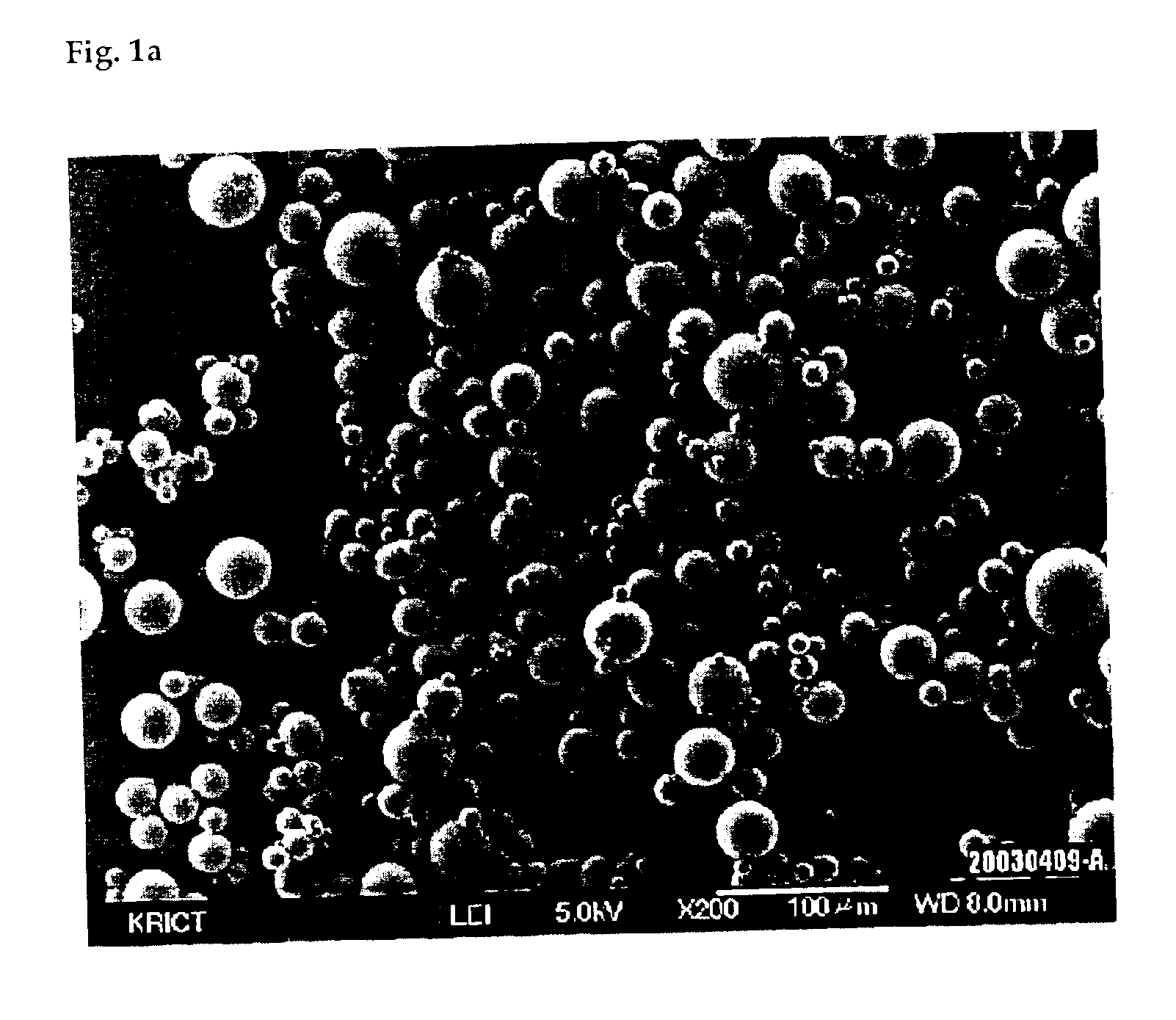

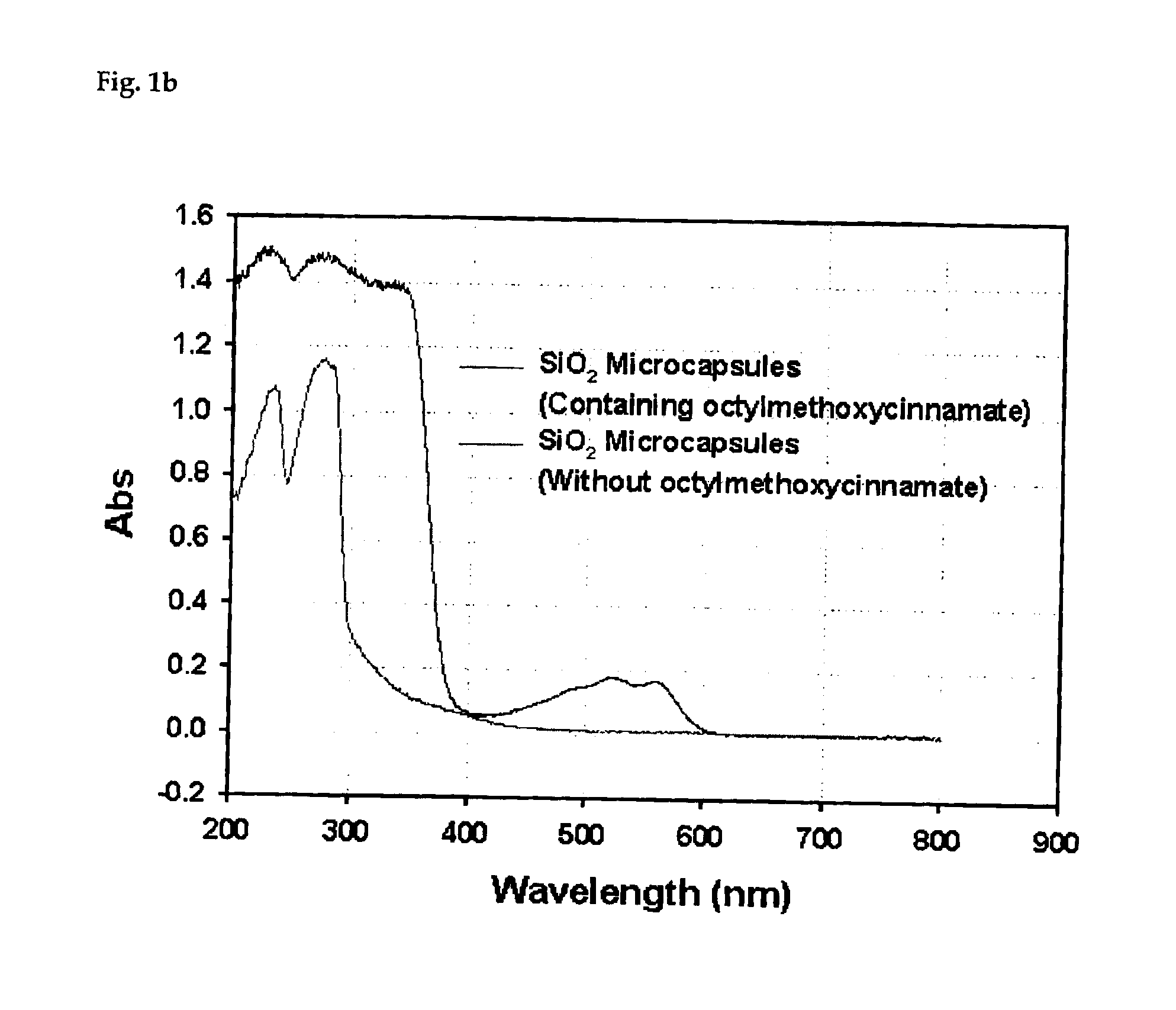

example 1

Of tetraethoxy orthosilicate(TEOS) 1160 g, first 160 g was slowly added to 0.01M aqueous solution of HCl 100 g for 3 hours and the remaining 1000 g was added for 1 hour. The reaction mixture was stirred for 12 hours to obtain a clear solution. The clear solution was evaporated under the pressure at a temperature of 50° C. to remove ethanol produced as a byproduct during the reaction. The resulting solution was a clear viscous precursor solution for lipophilic core material of which viscosity was about 35 cp and molecular weight was 3,200 Mw determined using gel permeation chromatography (GPC). 20 parts by weight of octylmethoxycinnamate as a core material was dissolved in the lipophilic precursor solution. 1.0 part by weight of aminopropyltriepoxysilane(APS) as an inner gelling agent was added into the resulting solution to produce emulsion solution. While an aqueous solution containing 1.0 part by weight of a surfactant (Triton X-100) in a separate container was stirred at a rate o...

example 2

Of tetraethoxy orthosilicate(TEOS) 7760 g, first 170 g was slowly added to 0.01M aqueous solution of HCl 100 g for 3 hours and the remaining 600 g was added for 1 hour. The reaction mixture was stirred for 12 hours to obtain a clear solution. The clear solution was evaporated under the pressure at a temperature of 50° C. to remove ethanol produced as a byproduct during the reaction. The resulting solution was a clear viscous precursor solution for hydrophilic core material of which viscosity was about 935 cp and molecular weight was 5,500 Mw determined using gel permeation chromatography (GPC). 20 parts by weight of 4-hydroxybenzophenone as a core material was dissolved in the hydrophilic precursor solution. 0.5 parts by weight of aminopropyltriepoxysilane(APS) as an inner gelling agent was added into the resulting solution to produce emulsion solution. While cyclohexene containing 1.5 parts by weight of a surfactant(Triton X-100) in a separate container was stirred at a rate of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com