Overlapping method for branched connecting line of hot-line robot

A technology for live operation and branch connection, applied in the field of electric power, can solve problems such as loss, hidden danger, economic and social benefits of power supply enterprises, and achieve the effect of avoiding negative impact, improving safety, and alleviating the contradiction of electricity complaints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It is easy to understand that, according to the technical solution of the present invention, without changing the essence of the present invention, those skilled in the art can imagine various implementations of the method for bonding the branch leads of the live working robot of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

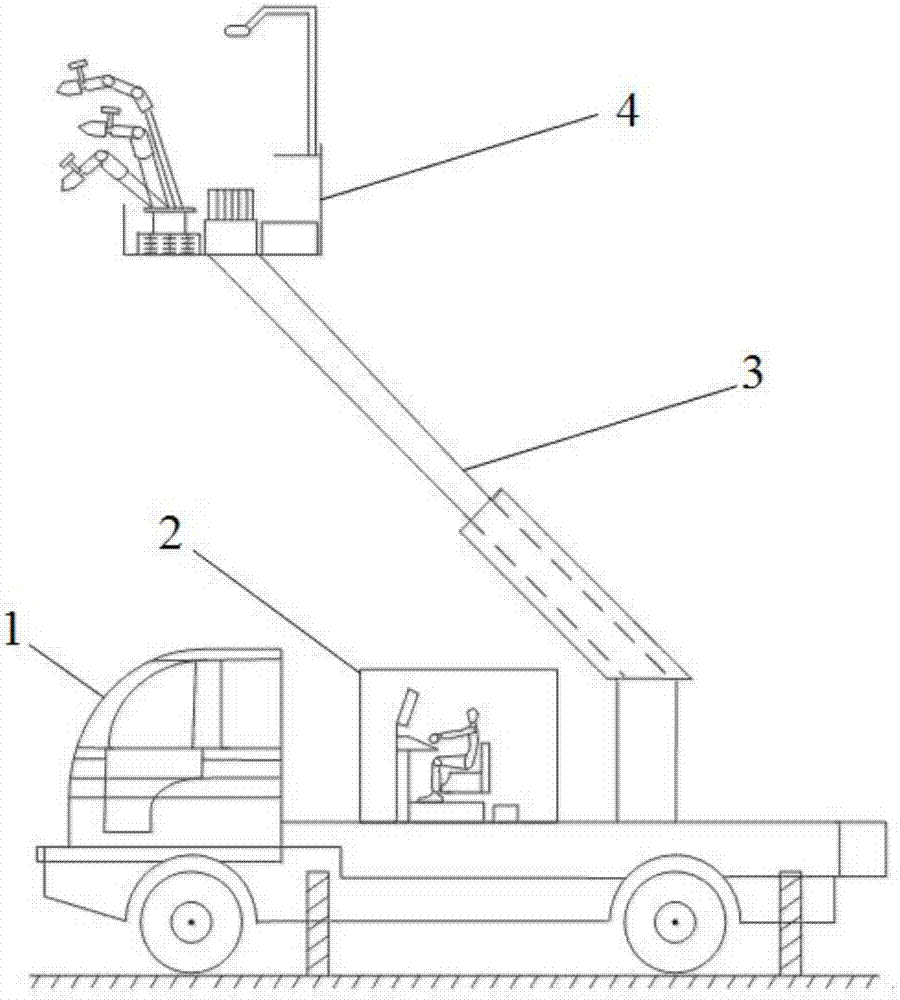

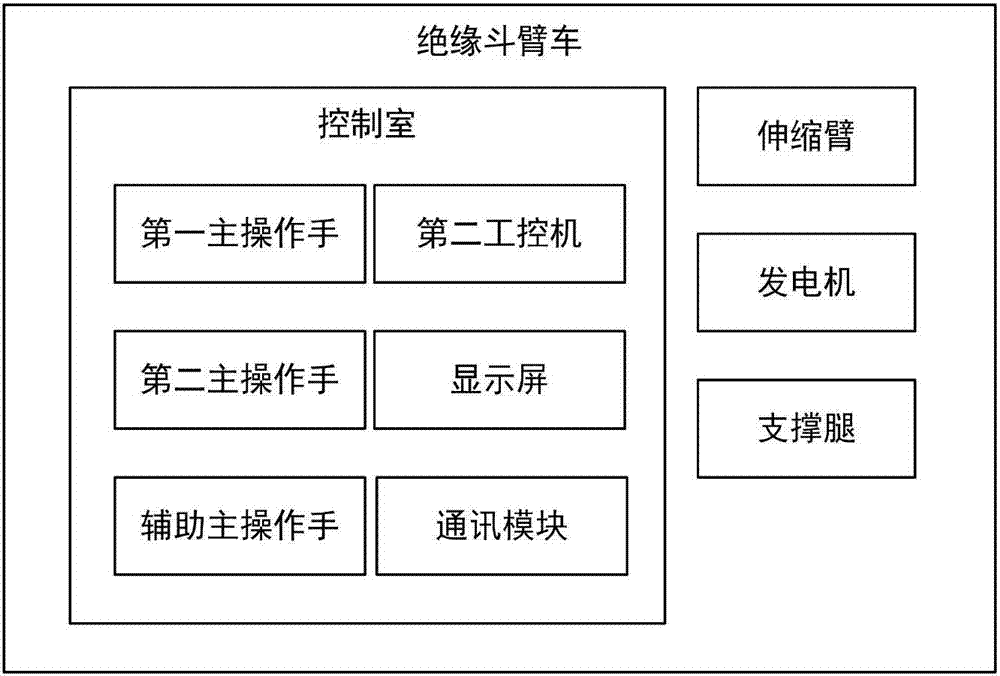

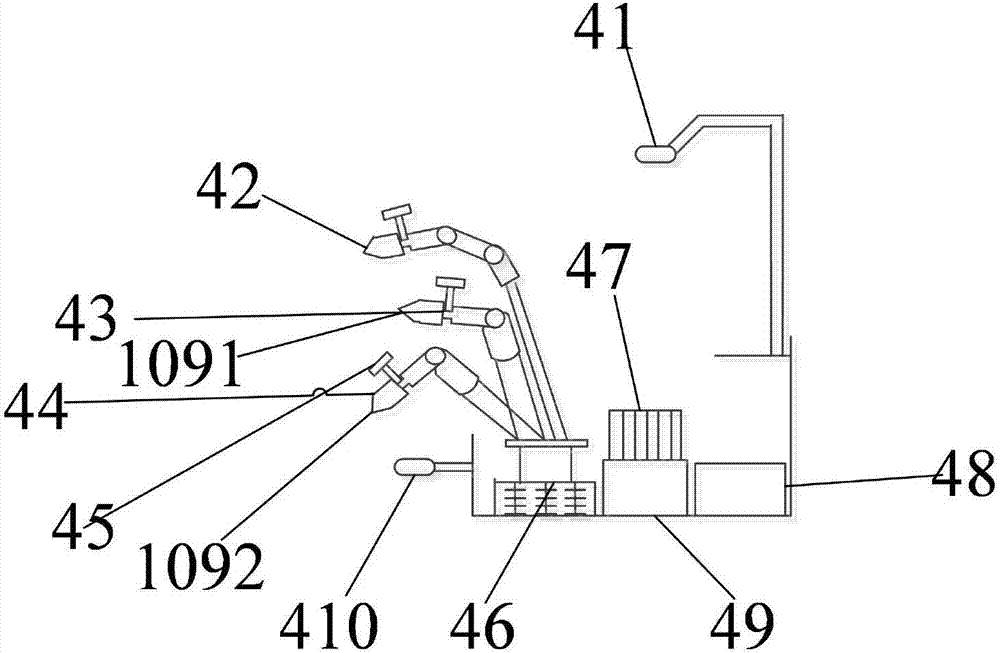

[0029] With reference to the accompanying drawings, the live working robot includes an insulated arm truck 1 , a control room 2 , a telescopic arm 3 , and a robot platform 4 . Among them, the control room 2 and the telescopic arm 3 are erected on the insulated bucket truck 1, and the end of the telescopic arm 3 is connected to the robot platform 4, and the fiber optic Ethernet com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com