Slurry shield starting tunnel portal sealing structure and construction method thereof

A technology of sealing structure and mud-water shield, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of slurry leakage, poor applicability, and non-adjustable gap, so as to expand the scope of use, improve the sealing effect, and avoid soil destabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

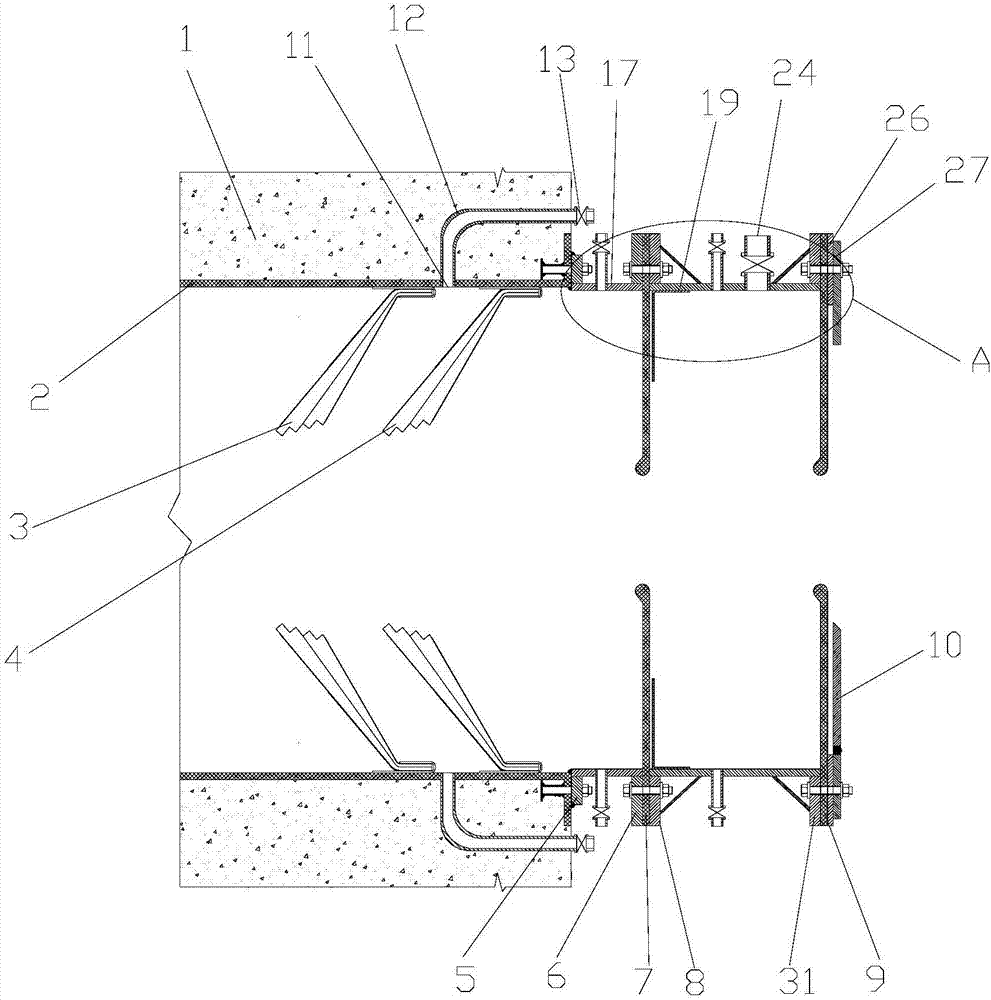

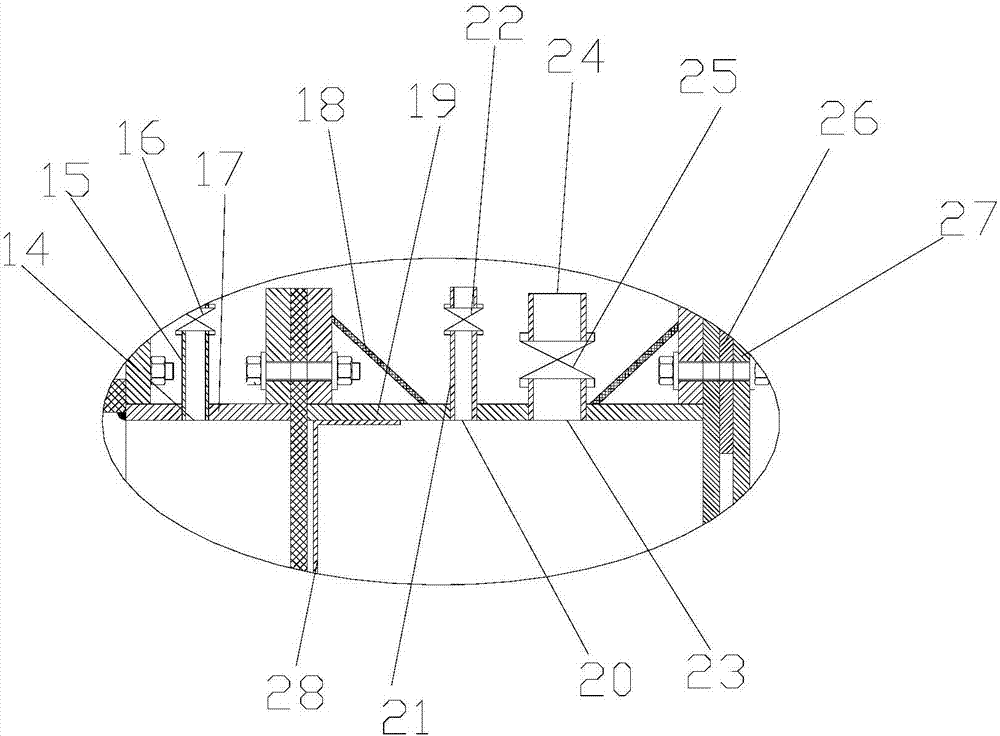

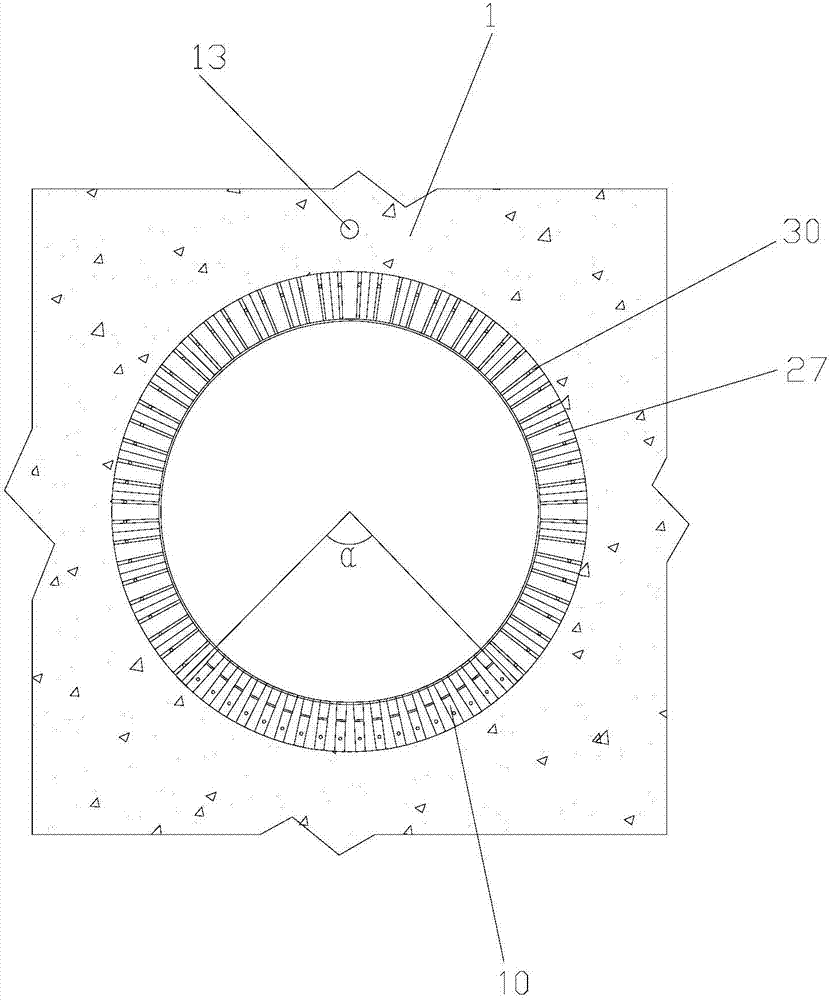

[0061] like figure 1 , figure 2 , image 3 and Figure 4 The sealing structure for the opening door of mud-water shield includes the first extended steel ring 17, the second extended steel ring 19 and the fixed circular ring 26 arranged in parallel at the tunnel door from the inside to the outside. The first extended steel ring 17 is fixedly connected with the door steel ring 2;

[0062] Two steel wire brushes are arranged on the inner wall circumference direction of the door steel ring 2, and the two steel wire brushes are arranged along the extension direction of the door steel ring 2, and the two steel wire brushes are respectively the first steel wire brush 3 And the second steel wire brush 4 positioned outside the first steel wire brush 3, the first steel wire brush 3 is composed of a plurality of first steel wire brushes, and the second steel wire brush 4 is composed of a plurality of second steel wire brushes , one end of the first wire brush and one end of the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com