Cylindrical member maintenance device

A maintenance equipment, cylindrical technology, used in bridge parts, bridge construction, cleaning methods using liquids, etc., can solve problems such as inability to clean the depths of adjacent strand grooves, wire brush wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

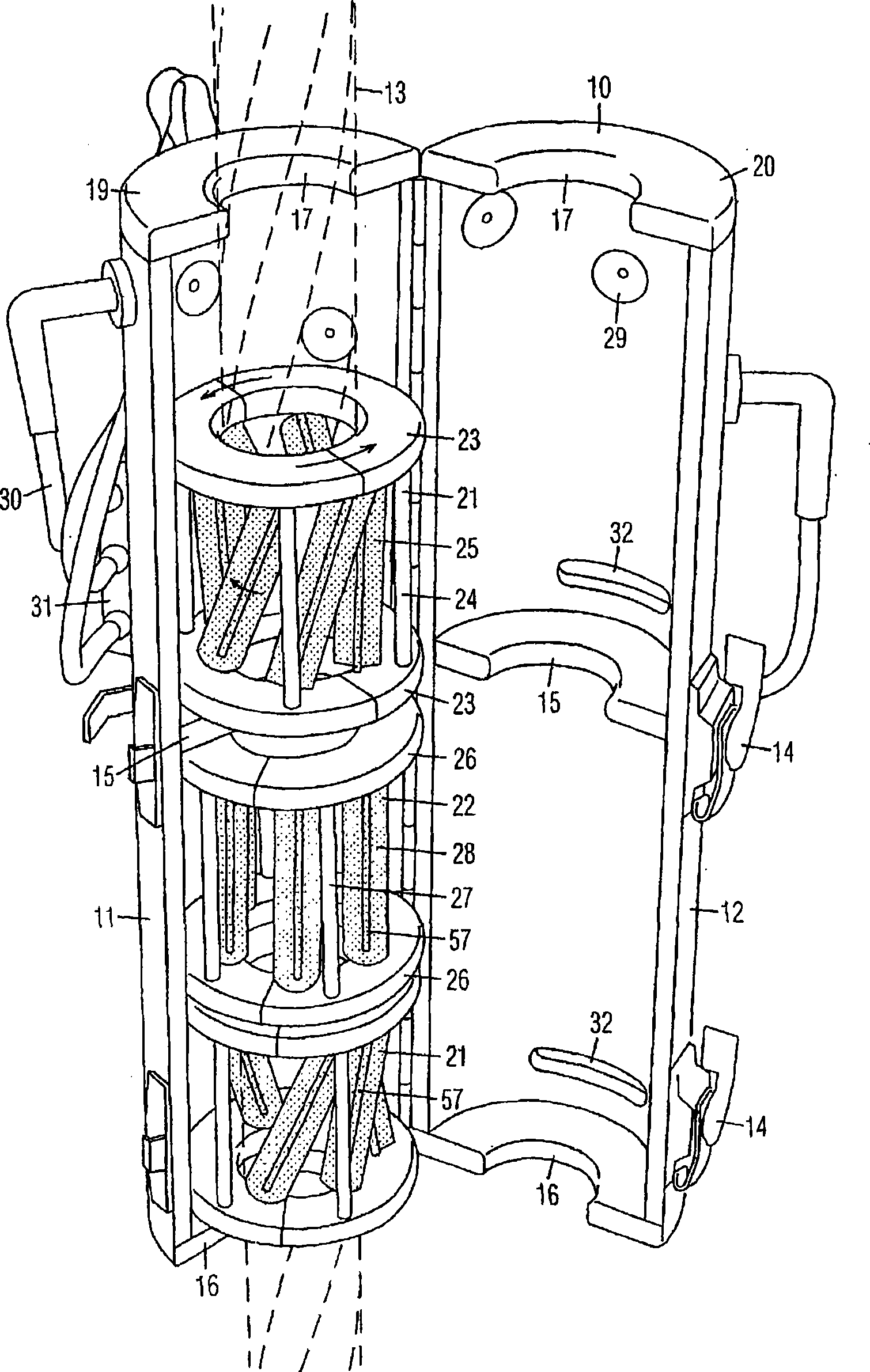

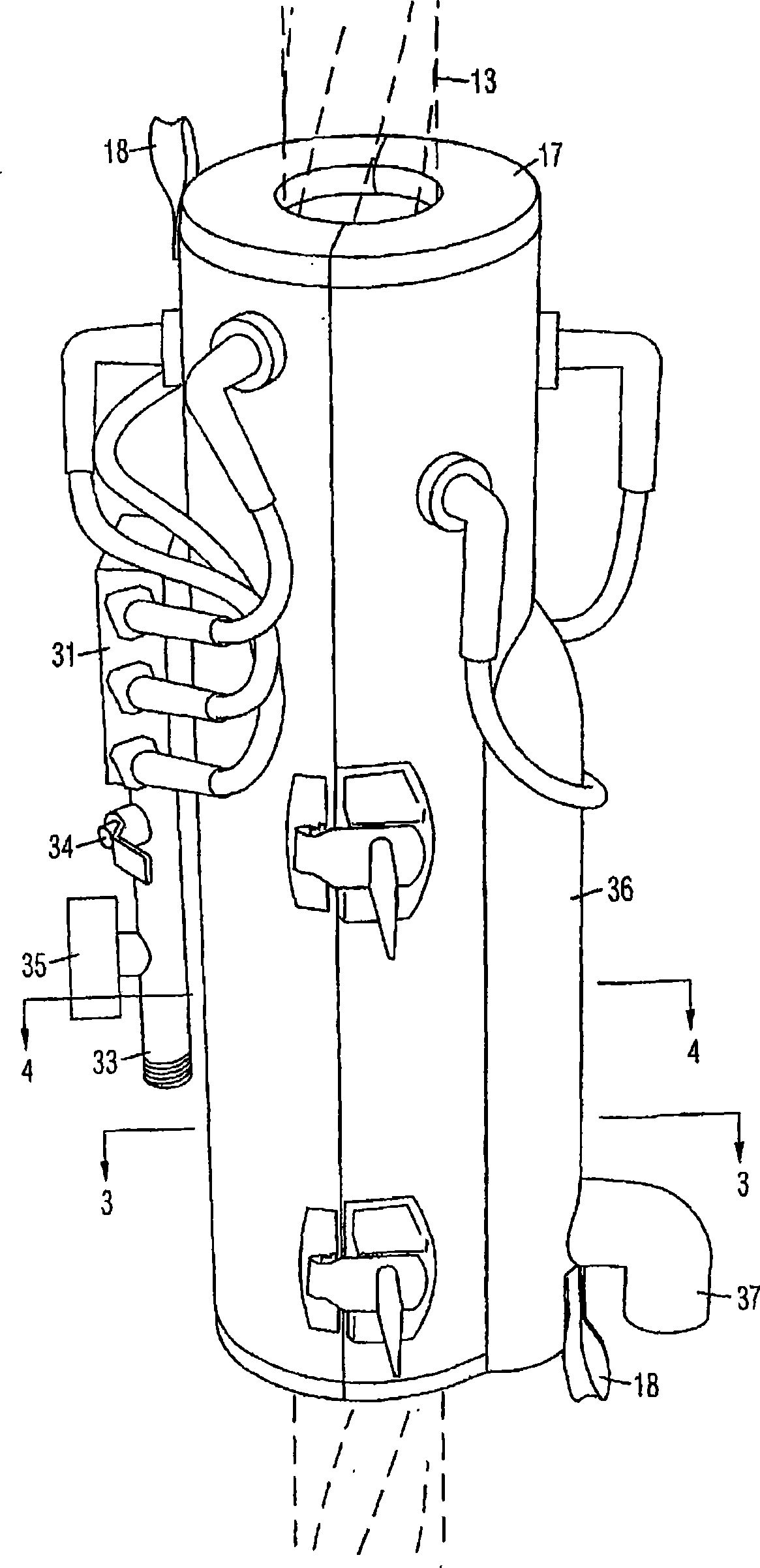

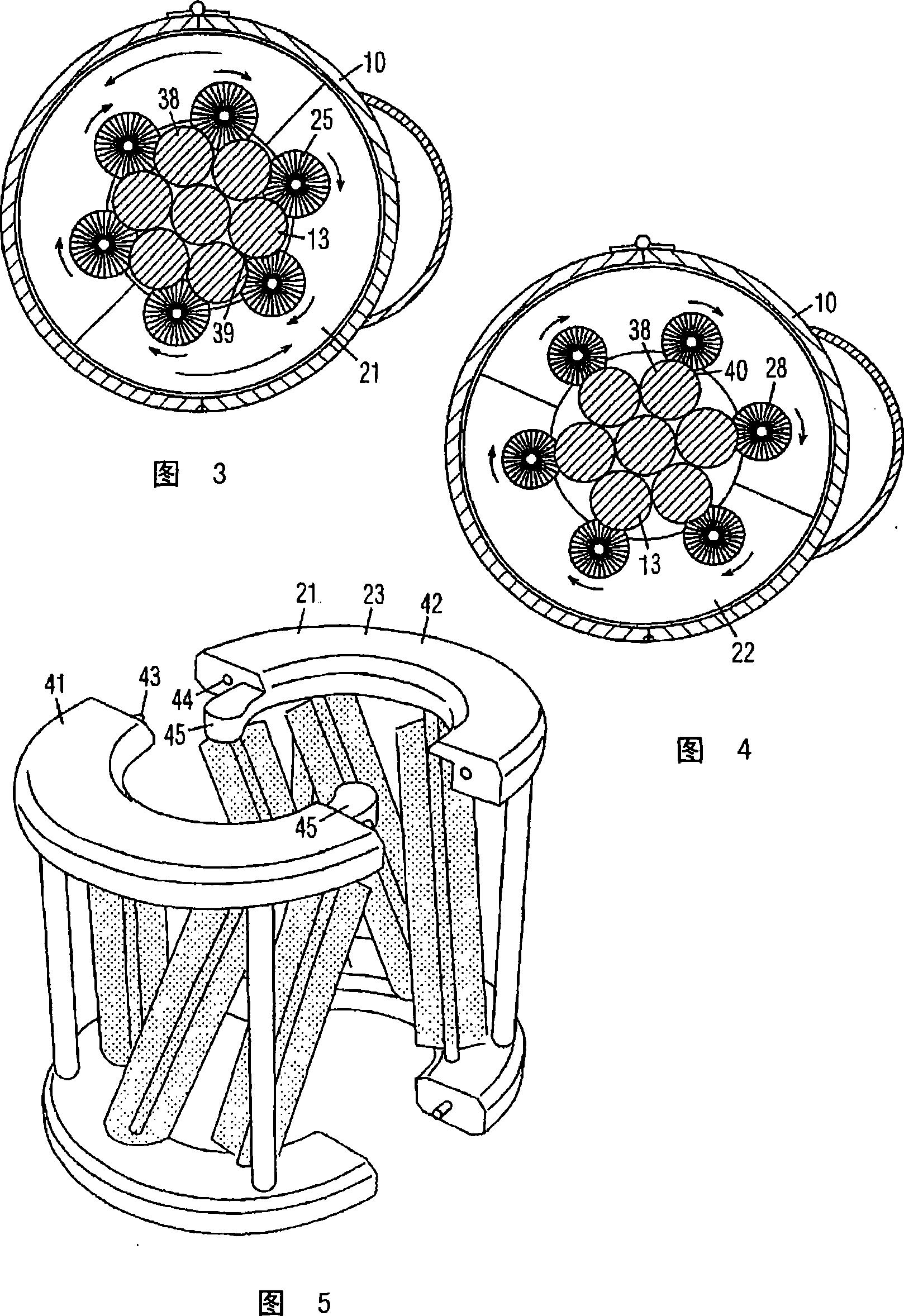

[0043] figure 1 :

[0044] The cylindrical member maintenance equipment in the open position is in the figure 1 Shown in perspective view. It comprises a housing 10 comprising two hinged housing halves 11 and 12 to close around a cylindrical member 13, such as a braided steel cable. The cleaner can be used to clean other types of cylindrical components, such as pipes. The housing halves 11 and 12 are locked together by a latch 14 after closing around the cylindrical member 13 .

[0045] Split alignment rings 15 and 16 in the housing align cylindrical member 13 therein and seal the interior of housing 10 from the external environment. A split seal ring 17 is located at the first end of the housing 10 . The sealing ring 17 has a slightly larger inner diameter than the inner diameters of the alignment rings 15 and 16 to avoid touching the cylindrical member 13 . The rings 15 - 17 each comprise two half rings 19 and 20 attached to respective housing halves 11 and 12 so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com