Pipeline external wall cleaning machine

A technology for cleaning machines and pipelines, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of low work efficiency, high labor intensity of workers, and poor quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

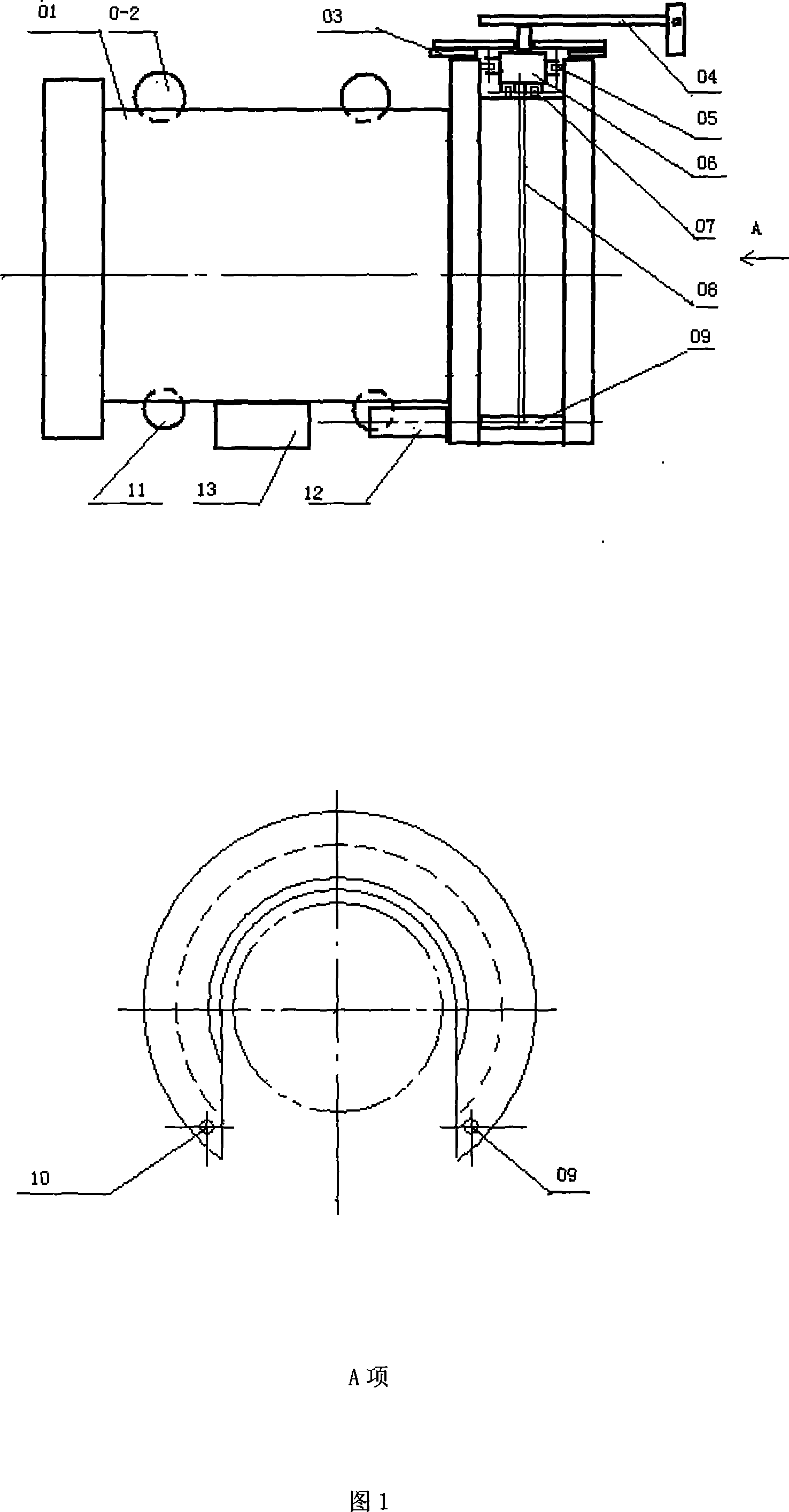

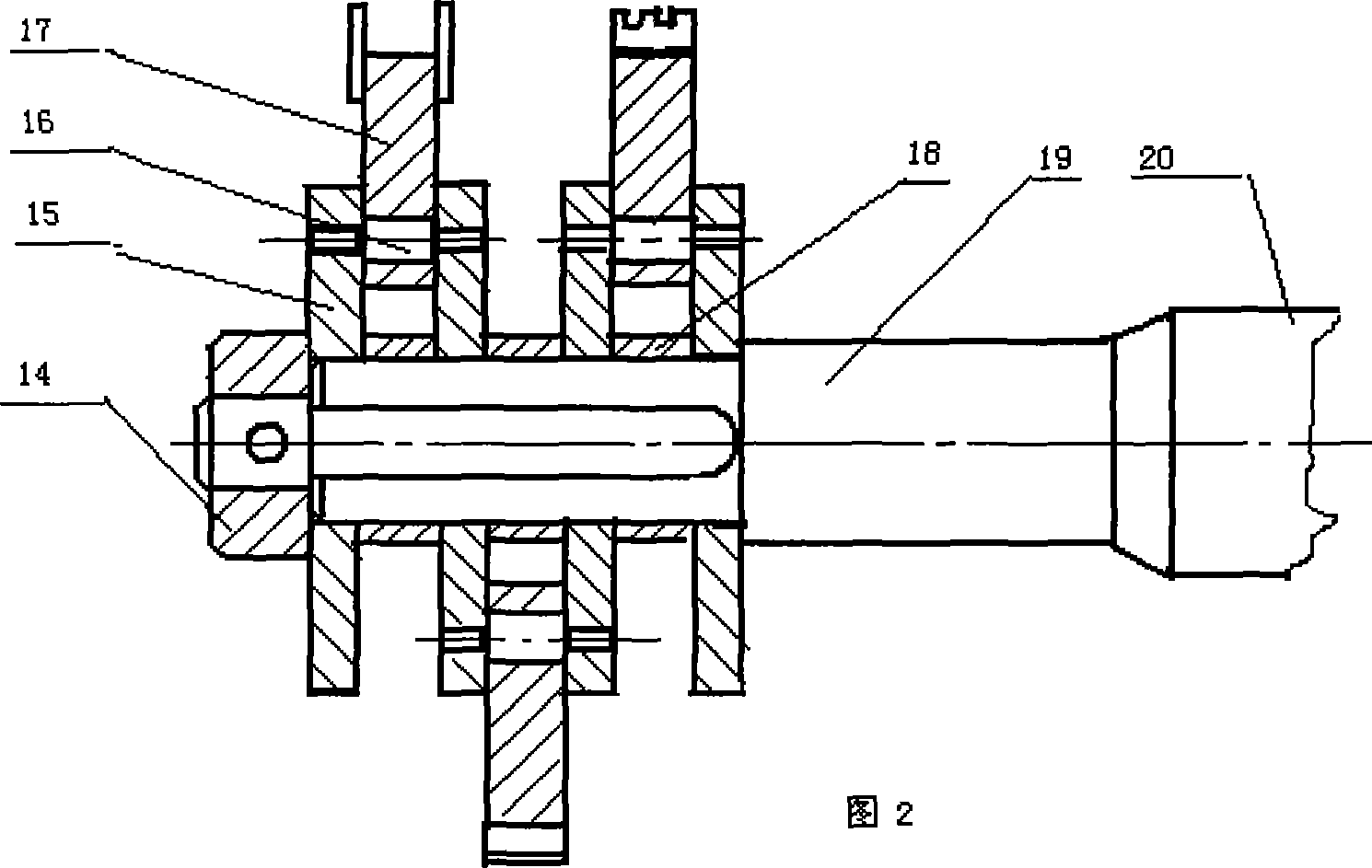

[0010] Figure 1 01 machine base 02 driving wheel 03 protective strip 04 working parts 05 lateral wheel 06 slider 07 radial wheel 08 wire rope 09 wire rope driving wheel 10 wire rope driven wheel 11 driven wheel 12 governor 13 counterweight

[0011] A pipeline outer wall cleaning machine shown in Fig. 1 is characterized in that: the base 01 is a cylinder with a lower opening, the opening width is slightly larger than the diameter of the pipeline to be cleaned, and can be walked on the pipeline, and the base 01 is equipped with Driving wheel 02 and driven wheel 11, the speed of travel can be steplessly adjusted, there is a circular track on the outer circumference of one end of the base 01, and a slide block 06 is installed in the circular track, and radial wheels 07 and lateral wheels are installed on the slide block 06. The wheel 05 is rollingly connected with the ring track, and a steel wire rope 08 is installed at the front and back of the slider 06. One of the two steel rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com