Dynamic storage and unwinding device for bag making machine

A technology of unwinding device and bag making machine, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve problems affecting production efficiency, equipment shutdown and waiting for materials, etc., and achieves easy maintenance, small size, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

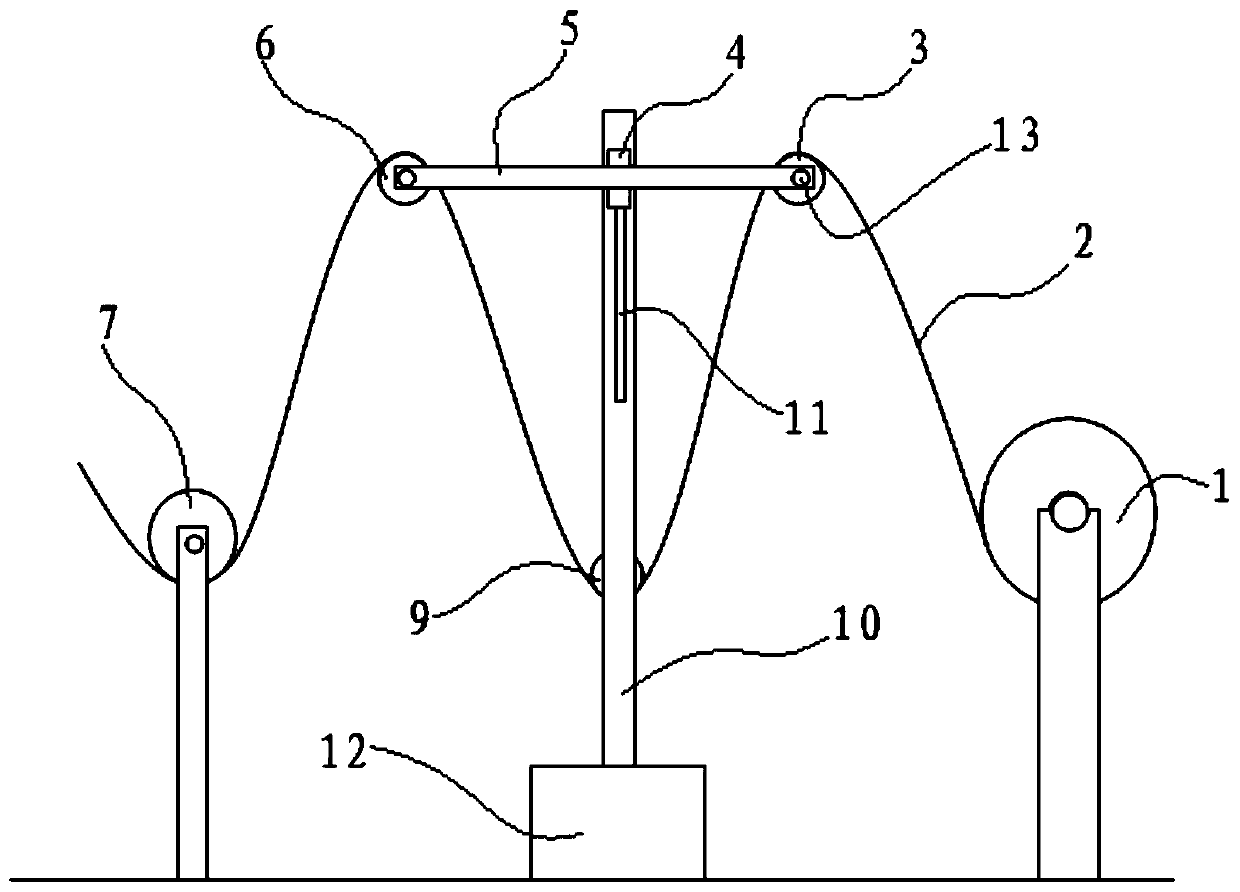

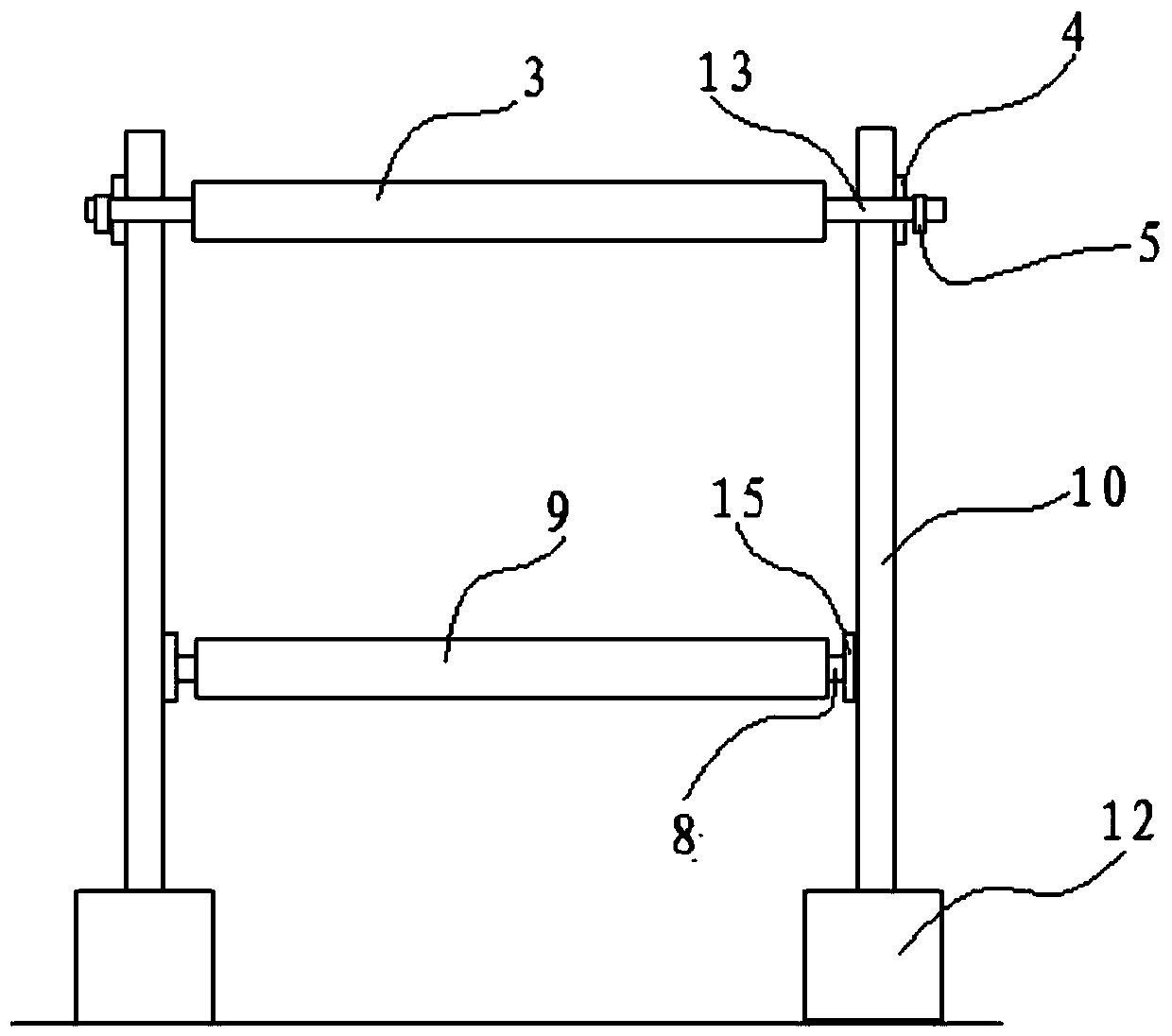

[0017] Referring to the accompanying drawings, reflecting a specific structure of the present invention, a dynamic storage mechanism is provided between the film roll 1 and the feed roller group 7 of the bag making machine, and the dynamic storage mechanism includes a storage roller group ; The storage roller group includes the upper guide roller 3 and the upper guide roller 6 at a high position, and the lower guide roller 9 at a low position is arranged between the two upper guide rollers.

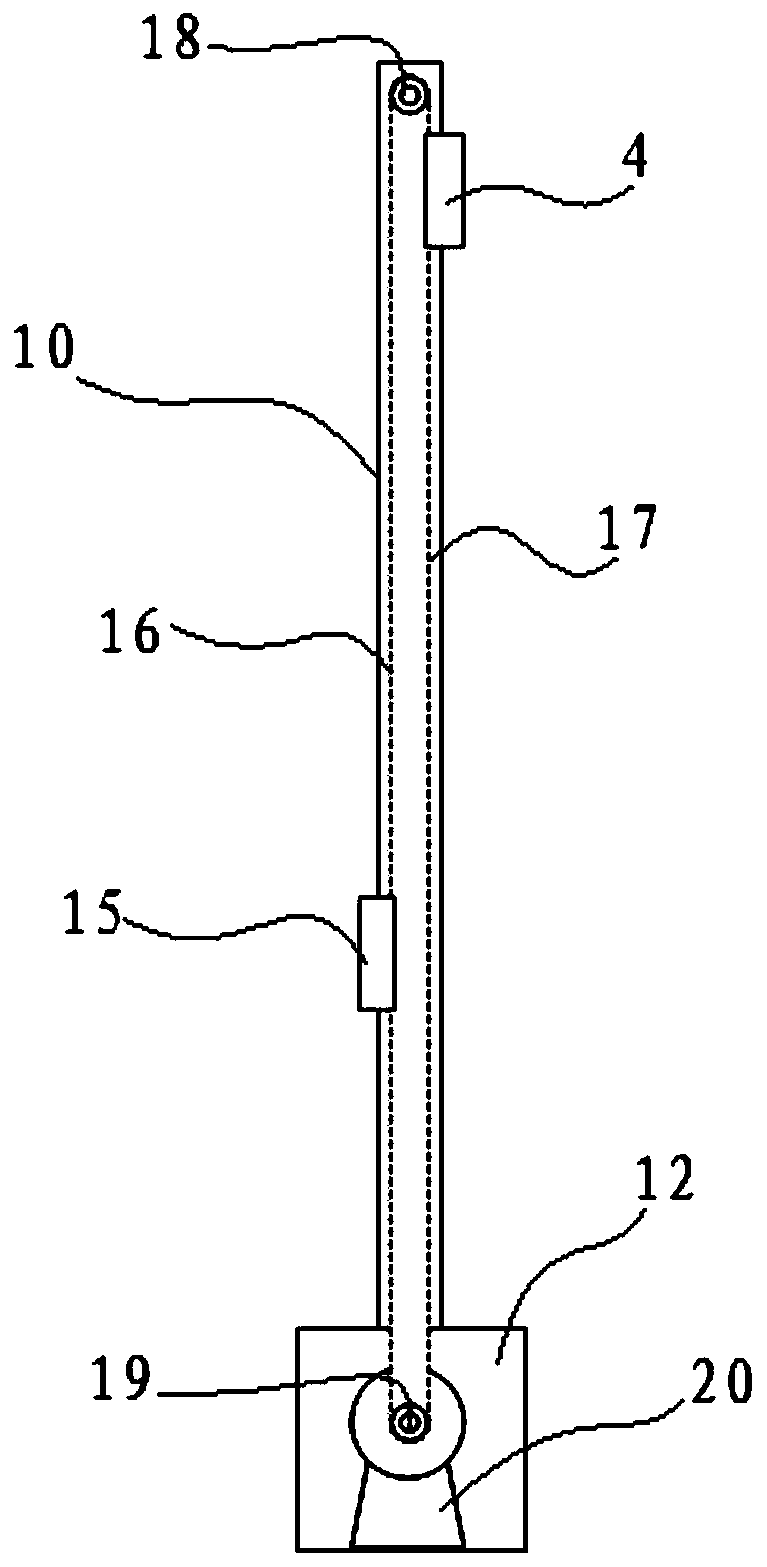

[0018] The film 2 drawn out from the film roll 1 bypasses the upper and lower guide rollers in a V-shaped distribution. The rotating shafts 13 at both ends of the two upper guide rollers are installed on the two ends of the cross arm 5, the middle part of the cross arm 5 is fixed on the lifting outer base 4 of the column 10, and the rotating shafts 8 at both ends of the lower guiding roller 9 are installed on the column. 10 on the inner base 15 of the lift.

[0019] The column 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com