Method for efficiently-stripped laminar inorganic material

A technology of inorganic materials and inorganic material layers, applied in the direction of inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve the problems of thick sheets, high energy consumption of mechanical methods, poor product performance, etc., and achieve sheet thickness thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

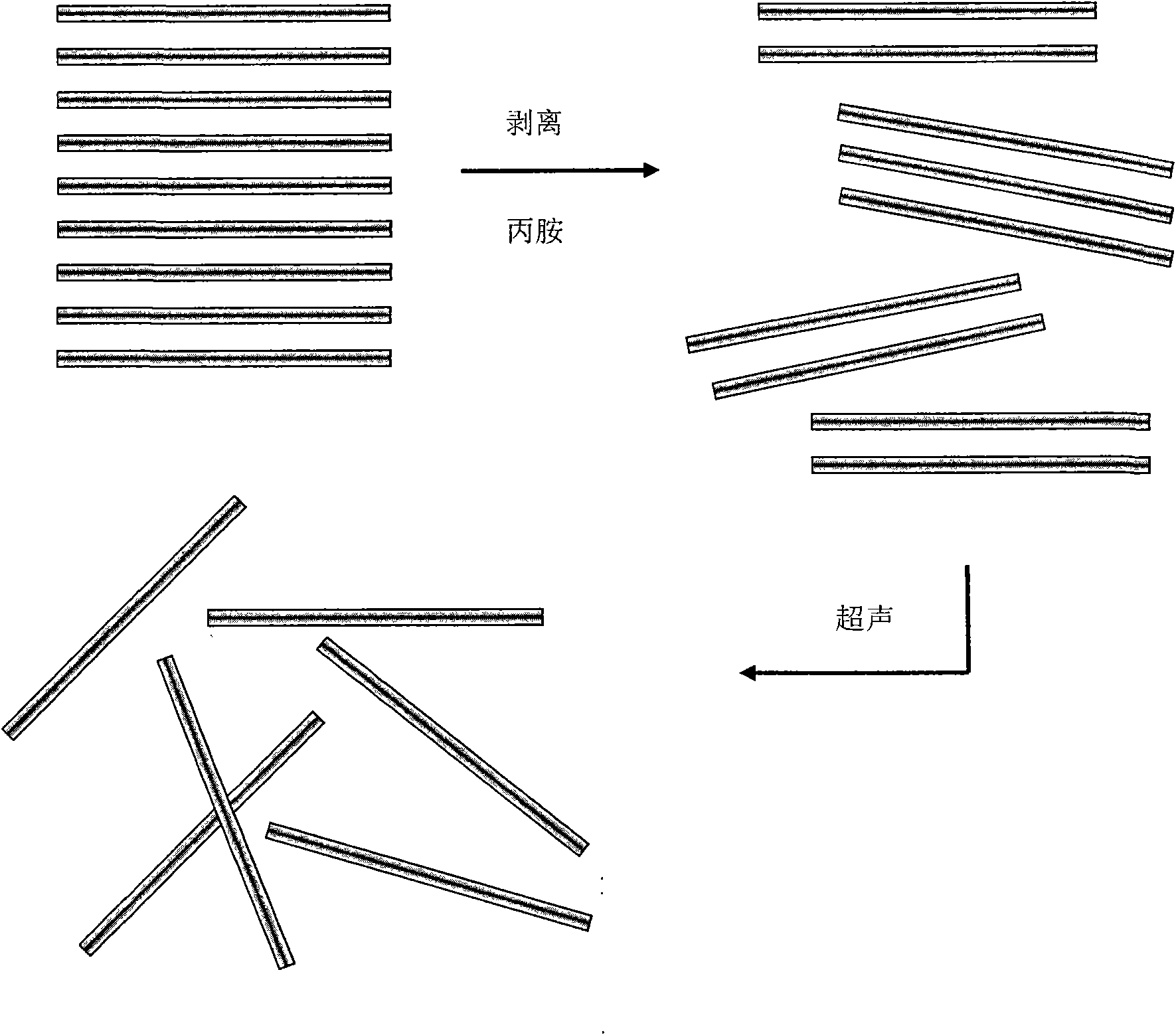

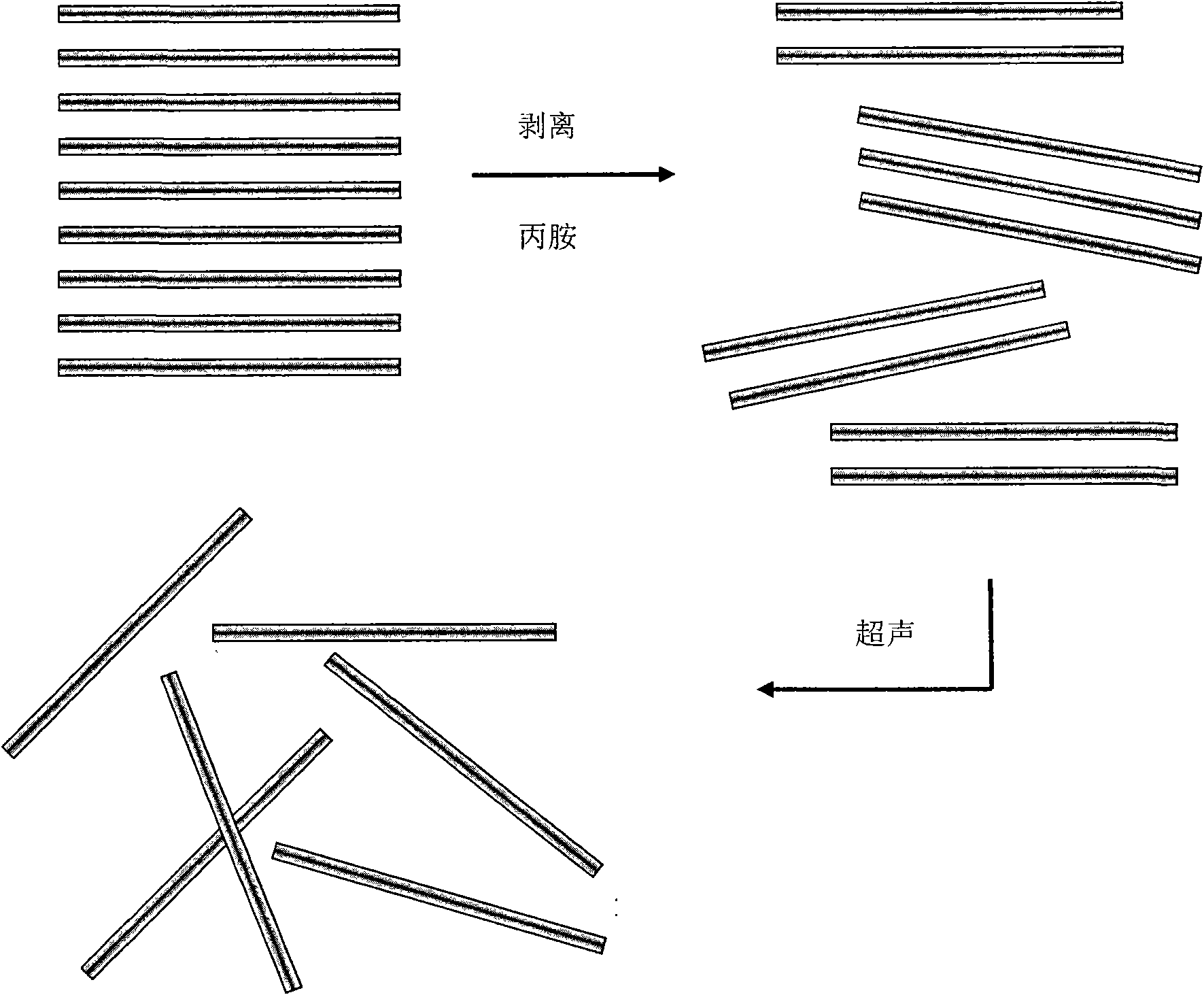

[0022] Step 1: Preparation of α-ZrP primary exfoliation by propylamine

[0023] Take 1 g of the synthesized α-ZrP powder and disperse it in distilled water with a liquid-solid ratio of 100 ml / g, and disperse evenly under ultrasonic conditions. According to the molar ratio n(amine):n(α-ZrP)=0.5:1, 8.5ml of 0.2mol / L propylamine solution was added respectively. Stir to form a gel.

[0024] Step 2: Efficient stripping of α-ZrP by ultrasonic method

[0025] Put the above-prepared colloid into a beaker, place it in an ultrasonic apparatus for 30 minutes, and then take it out, so that the α-ZrP can be peeled off more thoroughly.

[0026] Step Three: Finished Product

[0027] The above samples were centrifuged to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com