Hydrophilic boron nitride nanosheet and preparation method and application thereof

A technology of boron nitride and nanosheets, which is applied in the field of nanomaterials, can solve the problems of cumbersome experimental process, harsh reaction conditions, and large size of boron nitride nanosheets, and achieve simple experimental equipment, low production costs, and low environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

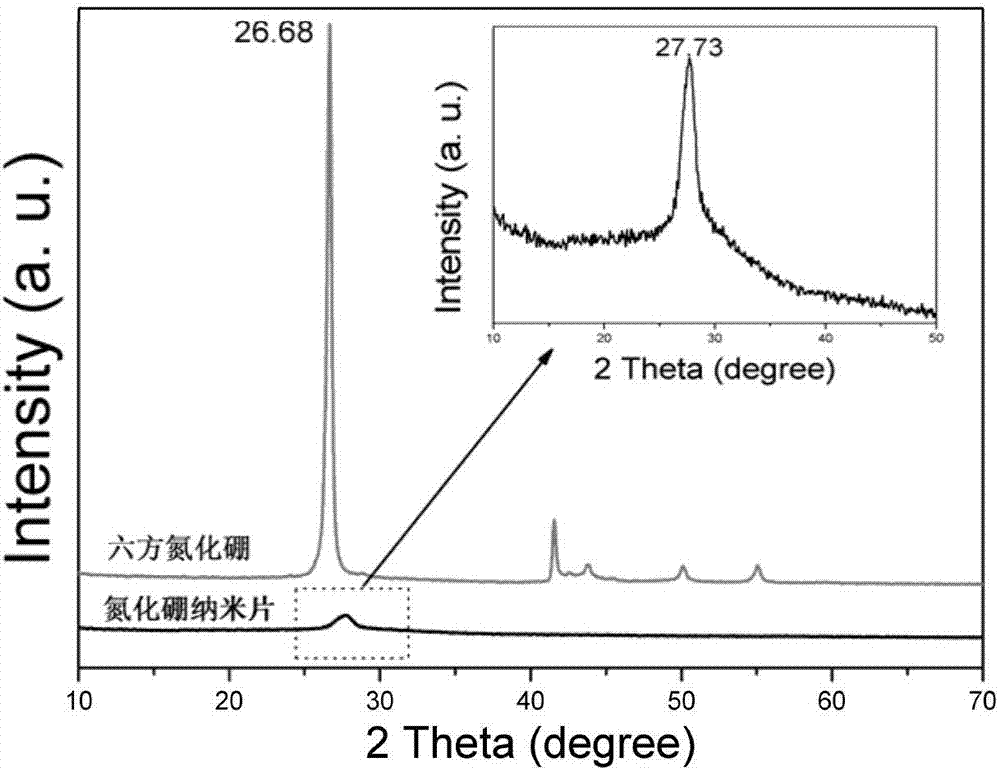

[0033] (1) Preparation of alkali ion intercalation boron nitride complex

[0034] A. Disperse the hexagonal boron nitride powder in 30mL ethanol to prepare a dispersion liquid. The concentration of the hexagonal boron nitride powder in the prepared dispersion liquid is 1mg / mL; then add 2mL concentration of 2.5mol to the dispersion liquid / L of potassium hydroxide aqueous solution, ultrasonically mixed to obtain a mixed solution;

[0035] B. Evenly transfer the mixed solution obtained in step A to the reaction kettle through a graduated cylinder, seal it; place it in an oven with a temperature of 180°C for 12 hours, wait to cool to room temperature, vacuum filter and wash with deionized water and collect the deposited The white powder on the microporous filter membrane is put into a vacuum drying oven to dry to remove excess water, and the alkali ion intercalation boron nitride compound can be obtained.

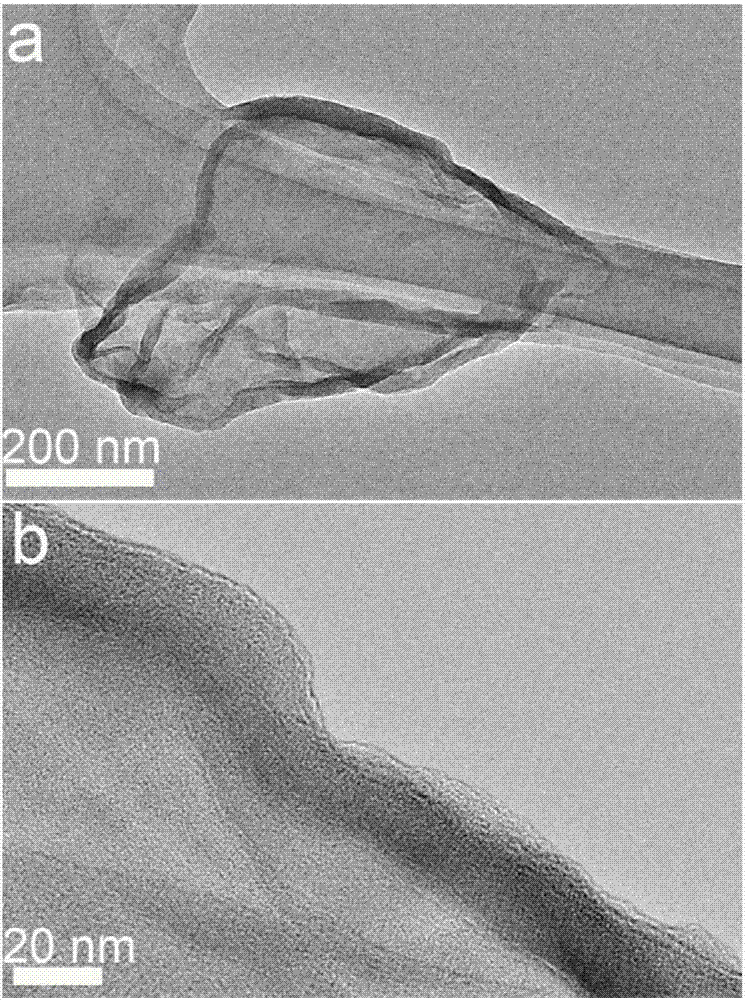

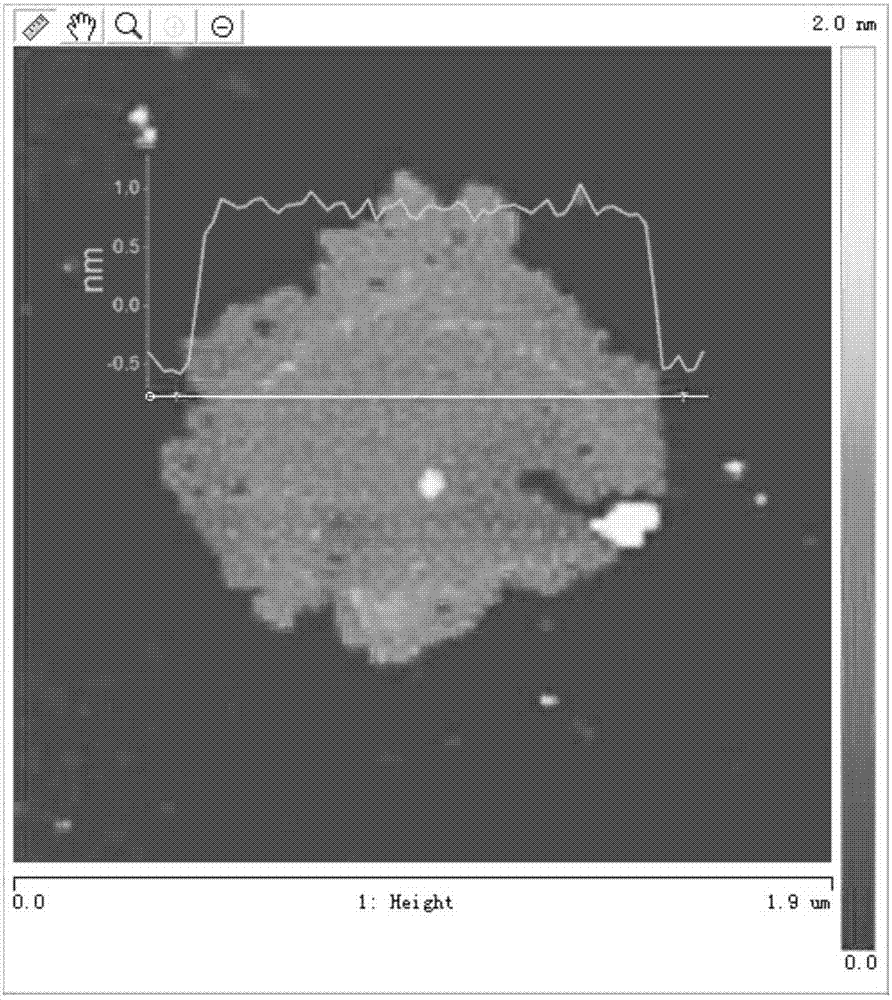

[0036] (2) Preparation of boron nitride nanosheets

[0037] C. Redisper...

Embodiment 2

[0041] (1) Preparation of alkali ion intercalation boron nitride complex

[0042]A. Disperse the hexagonal boron nitride powder in 30mL of ethylene glycol to prepare a dispersion liquid. The concentration of the hexagonal boron nitride powder in the prepared dispersion liquid is 0.5mg / mL; then add 1mL concentration to the dispersion liquid 2.5mol / L aqueous sodium hydroxide solution, ultrasonically mixed to obtain a mixed solution;

[0043] B. Evenly transfer the mixed solution obtained in step A to the reaction kettle through a graduated cylinder, seal it; place it in an oven with a temperature of 160°C for 16 hours, wait to cool to room temperature, vacuum filter and wash with deionized water and collect the deposited The white powder on the microporous filter membrane is put into a vacuum drying oven to dry to remove excess water, and the alkali ion intercalation boron nitride compound can be obtained.

[0044] (2) Preparation of boron nitride nanosheets

[0045] C. Redisp...

Embodiment 3

[0048] (1) Preparation of alkali ion intercalation boron nitride complex

[0049] A. Disperse the hexagonal boron nitride powder in 30mL of glycerol to prepare a dispersion. The concentration of the hexagonal boron nitride powder in the prepared dispersion is 2mg / mL; mol / L lithium hydroxide aqueous solution, and ultrasonically mix to obtain a mixed solution;

[0050] B. Evenly transfer the mixed solution obtained in step A to the reaction kettle through a graduated cylinder, seal it; place it in an oven with a temperature of 120°C for 24 hours, wait to cool to room temperature, vacuum filter and wash with deionized water and collect the deposited The white powder on the microporous filter membrane is put into a vacuum drying oven to dry to remove excess water, and the alkali ion intercalation boron nitride compound can be obtained.

[0051] (2) Preparation of boron nitride nanosheets

[0052] C. Redisperse the alkali ion-intercalated boron nitride complex obtained in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com