Method for solvothermal preparation of fluorescent carbon nitride quantum dots

A fluorescent carbon nitride and quantum dot technology, applied in the field of nanomaterials, can solve the problems of harsh reaction conditions, human and environmental hazards, and long reaction time, and achieve the effects of stable water solubility, good dispersibility, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

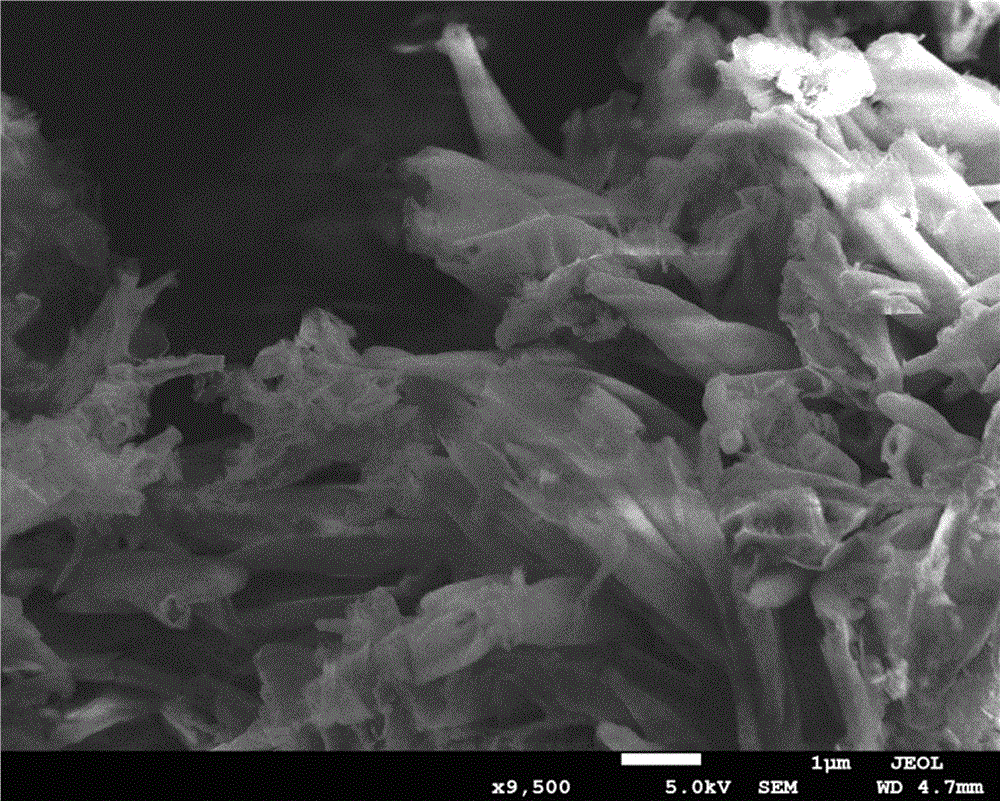

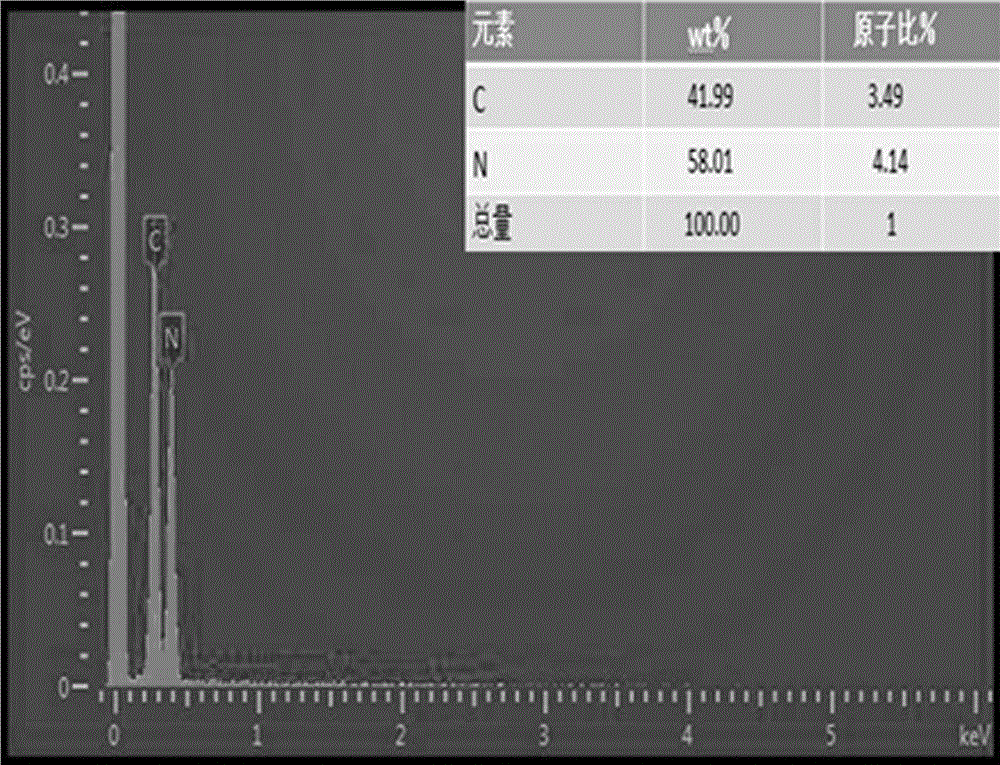

[0027] (1) Preparation of graphite phase carbon nitride powder

[0028] 18 g of melamine was loaded into an alumina porcelain boat and placed in a muffle furnace. Ramp to 600 °C at a rate of 3 °C / min, hold for 2 hours, and then cool to room temperature at a rate of 3 °C / min. Put it into an agate mortar and grind to obtain 5.84 g of graphite phase carbon nitride powder.

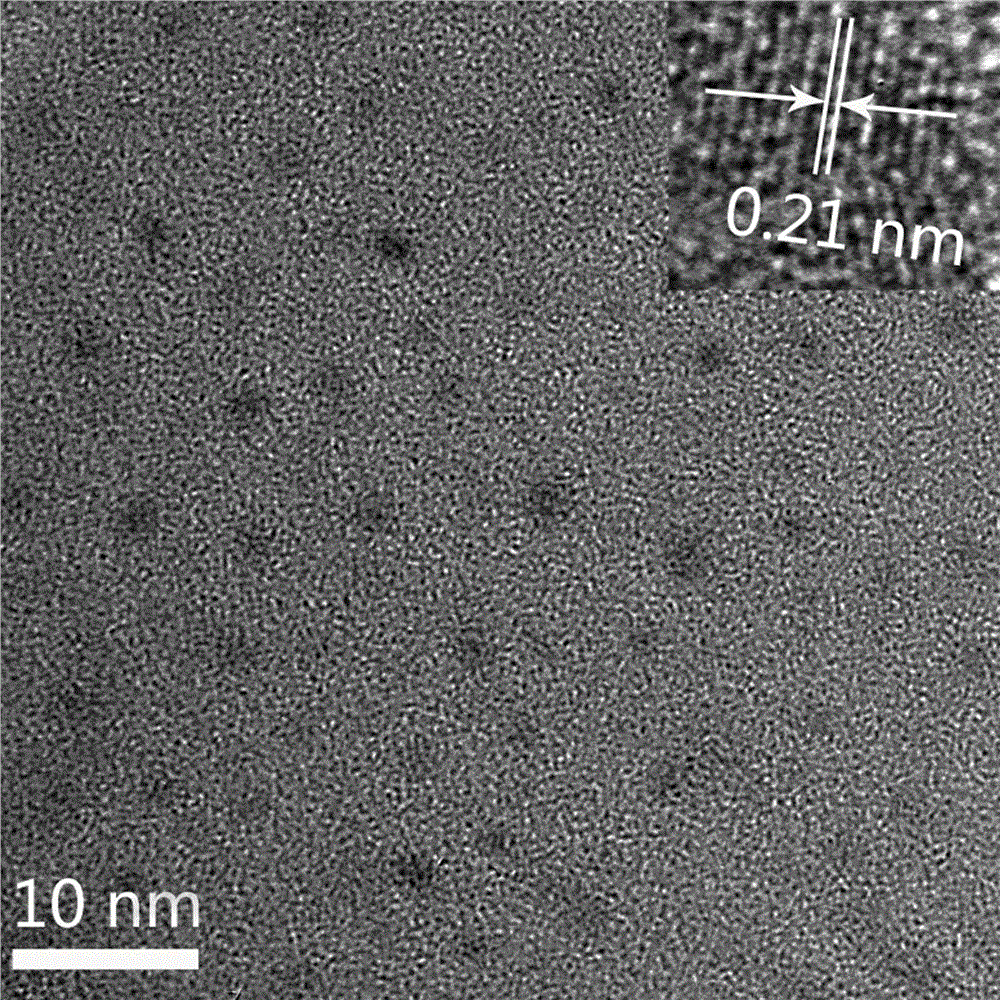

[0029] (2) Preparation of carbon nitride quantum dots

[0030] Disperse 30 mg of graphitic carbon nitride powder in (1) into 30 ml of absolute ethanol solution, add 0.45 ml of potassium hydroxide, and mix ultrasonically for 5 min. Transfer the mixed solution to a reaction kettle, seal it, put it in an oven, raise the temperature to 180°C, maintain it for 16h, and cool it down to room temperature naturally. The treated dispersion was collected by vacuum filtration to obtain a pale yellow filtrate. The filtrate was dialyzed in a 10,000 Da dialysis bag until neutral. The obtained dialysate was frozen, and th...

Embodiment 2

[0033] Disperse 40 mg of graphitic carbon nitride powder obtained in Example (1) into 30 ml of glycerin solution, add 0.30 ml of sodium hydroxide, and mix ultrasonically for 5 min. Transfer the mixed solution (mixed solution) to a reaction kettle, seal it, put it in an oven, raise the temperature to 200 °C, maintain it for 12 h, and cool it down to room temperature naturally. The treated mixture was collected by vacuum filtration to obtain a pale yellow filtrate. The filtrate was dialyzed in a 10000 Da dialysis bag until neutral. The obtained dialysate was frozen, and then freeze-dried at a temperature of -45°C and an air pressure of 20 Pa to obtain solid carbon nitride quantum dots.

Embodiment 3

[0035] Disperse 50 mg of the graphitic carbon nitride powder obtained in Example (1) in 40 ml of methanol solution, add 0.35 ml of lithium hydroxide, and ultrasonically mix for 5 min. The mixed solution was transferred to a reaction kettle, sealed, put into an oven, heated to 120 °C, maintained for 10 h, and cooled to room temperature naturally. The treated mixture was collected by vacuum filtration to obtain a pale yellow filtrate. Fill the filtrate into 8000 Da dialysis bags until neutral. The obtained dialysate was frozen, and then freeze-dried at a temperature of -40 °C and an air pressure of 10 Pa to obtain solid carbon nitride quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com