Walnut peeling device

A technology of walnut green peel and one pair, which is applied in the field of walnut green peel detaching machine, can solve the problems of leakage, walnut crushing, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

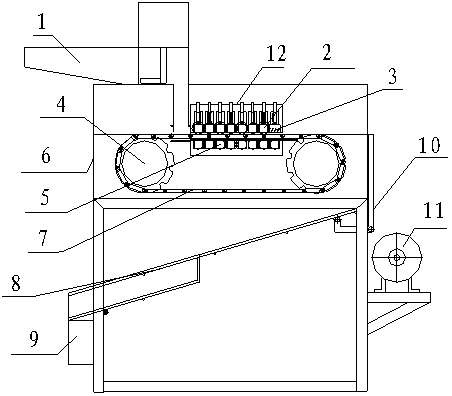

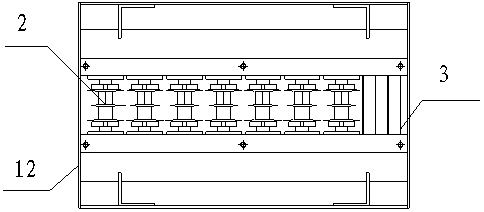

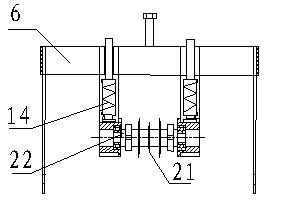

[0024] A kind of walnut green skin detaching machine, comprises frame 6, feeding hopper 1, a pair of sprockets 4, drive chain 7, sprocket driving device, tool rest seat 12, cutting device, grating type blade 3, separating screen 8, The discharge port 9 is composed of a pair of sprockets 4 and the transmission chain 7 engaged with it to form a conveyor belt. The cutting device and the grid type blade 3 are arranged on the knife holder seat 12. The cutting device is respectively arranged on the upper and lower sides of the conveyor belt. The cutting device 2 and the lower cutting device 5 are formed, and the grid type blade 3 is arranged at the end of the cutting device. Both the upper cutting device 2 and the lower cutting device 5 are composed of a bearing 22 and a disc blade 21 fixed on the bearing 22 . Since the walnut is a sphere, in order to ensure that the walnut skin is evenly cut, there are three disc blades 21, which are equally spaced and parallel fixed on the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com