Leak-stopping agent for petroleum drilling, preparation method, and application thereof

A technology for oil drilling and loss-stopping agent, which can be used in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., and can solve problems such as poor leakage-stopping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

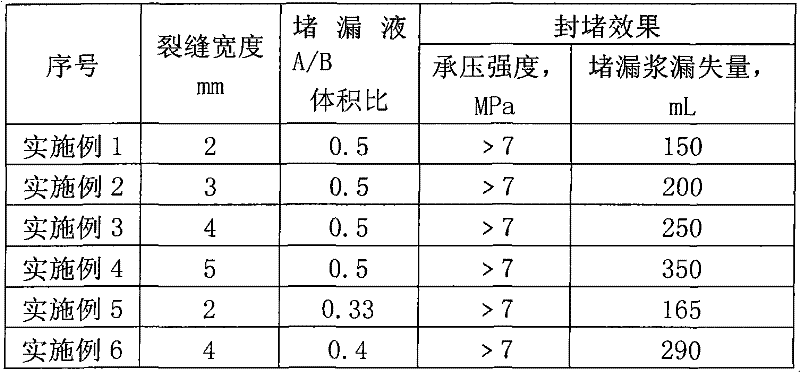

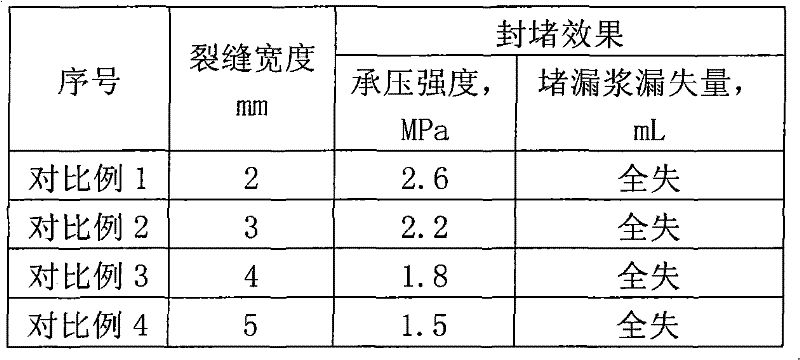

Examples

Embodiment 1

[0037] Plugging fluid A:

[0038] water: 100;

[0039] Alginate: 0.5;

[0040] The plugging fluid B is:

[0041] water: 100;

[0042] Oil well cement: 200;

[0043] 3mm polyester fiber: 0.5.

[0044] The configuration method of plugging solution A is: add alginate into water and stir for 15 minutes;

[0045] The configuration method of the plugging fluid B is as follows: water and oil well cement are first configured into cement slurry, and then fibers are added.

[0046] Plugging liquid A and plugging liquid B are sequentially added into the plugging simulation device at a volume ratio of 1:2 (man-made crack width is 2 mm), and slowly pressurized to 7 MPa (the maximum allowable pressure of the instrument is 7 MPa), and after 30 minutes the pressure It is reduced to 6.5MPa, indicating that the pressure-bearing strength of the plugging agent can reach 7MPa.

Embodiment 2

[0048] Plugging fluid A:

[0049] water: 100;

[0050] Alginate: 0.7;

[0051] Fine walnut shells: 3.

[0052] The plugging fluid B is:

[0053] water: 100;

[0054] Oil well cement: 220;

[0055] 3mm polypropylene fiber: 0.5.

[0056] The configuration method of plugging solution A is as follows: first prepare the alginate aqueous solution, stir for 15 minutes, and then add fine walnut shells;

[0057] The configuration method of the plugging fluid B is as follows: first prepare the cement slurry, and then add the fiber.

[0058] Plugging liquid A and plugging liquid B are sequentially added into the plugging simulation device at a volume ratio of 1:2 (man-made fracture width is 3 mm), and slowly pressurized to 7 MPa (the maximum allowable pressure of the instrument is 7 MPa), and after 30 minutes the pressure down to 6.8MPa, indicating that the pressure-bearing strength of the plugging agent can reach 7MPa.

Embodiment 3

[0060] Plugging fluid A:

[0061] water: 100;

[0062]Alginate: 0.7;

[0063] Medium walnut shells: 4.

[0064] The plugging fluid B is:

[0065] water: 100;

[0066] Oil well cement: 225;

[0067] 5mm polyester fiber: 0.6.

[0068] The configuration method of plugging solution A is as follows: first prepare the alginate aqueous solution, stir for 15 minutes, and then add walnut shells;

[0069] The configuration method of the plugging fluid B is: first configure the cement slurry, and then add the fiber;

[0070] Plugging liquid A and plugging liquid B are sequentially added into the plugging simulation device at a volume ratio of 1:2 (man-made fracture width is 4 mm), and slowly pressurized to 7 MPa (the maximum allowable pressure of the instrument is 7 MPa), and after 30 minutes the pressure down to 6.7MPa, indicating that the pressure-bearing strength of the plugging agent can reach 7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bearing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com