Preparation method of lysozyme

A technology of lysozyme and solution, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of long production cycle, environmental pollution, low resource utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

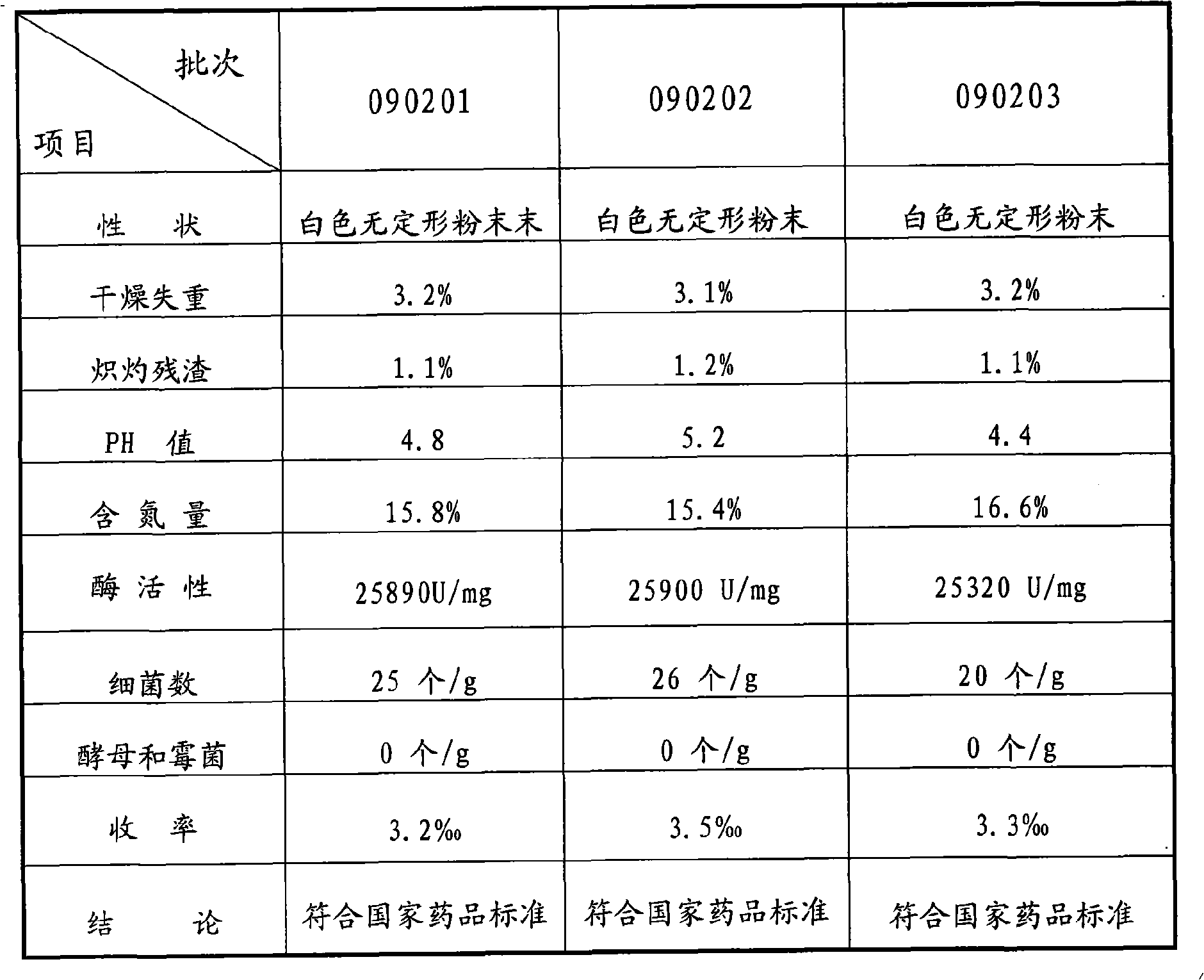

Examples

Embodiment 1

[0023] A preparation method of lysozyme, the steps of the method are,

[0024] a. Pretreatment: Use running water to spray and wash to remove sundries and dirt on the surface of fresh eggs, then soak in a chlorine dioxide solution with a chlorine dioxide content of 20mg / L for 25 minutes, and blow off the surface of eggs with hot air after soaking. Use an egg beater to break the shell and separate the egg white and egg yolk, and the egg white enters the raw material storage tank after being sterilized;

[0025] b. Separation and purification: under stirring, dilute the egg white in the raw material storage tank with water 0.8 times the weight of the egg white to obtain egg white liquid, adjust the pH value of the egg white liquid to 6.5 with dilute hydrochloric acid solution, and then use a plate and frame filter press Remove the sediment and solid impurities in the egg white liquid, and then send it to a homogenizer for homogenization treatment for 15 minutes. The homogenized ...

Embodiment 2

[0029] A preparation method of lysozyme, the steps of the method are,

[0030] a. Pretreatment: Use flowing water to spray and wash to remove sundries and dirt on the surface of fresh eggs, and then soak in a chlorine dioxide solution with a chlorine dioxide content of 30mg / L for 15 minutes, and then blow off the eggs on the surface with hot air after soaking. Use an egg beater to break the shell and separate the egg white and egg yolk, and the egg white enters the raw material storage tank after being sterilized;

[0031] b. Separation and purification: under stirring, dilute the egg white in the raw material storage tank with water 1.2 times the weight of the egg white to obtain egg white liquid, adjust the pH value of the egg white liquid to 5.0 with dilute hydrochloric acid solution, and then use a plate and frame filter press Remove the sediment and solid impurities in the egg white liquid, and then send it to a homogenizer for homogenization treatment for 25 minutes. The...

Embodiment 3

[0035] A preparation method of lysozyme, the steps of the method are,

[0036] a. Pretreatment: Use running water to spray and wash to remove sundries and dirt on the surface of fresh eggs, then soak in a chlorine dioxide solution with a chlorine dioxide content of 25mg / L for 20 minutes, and blow off the surface of eggs with hot air after soaking. Use an egg beater to break the shell and separate the egg white and egg yolk, and the egg white enters the raw material storage tank after being sterilized;

[0037]b. Separation and purification: under stirring, dilute the egg white in the raw material storage tank with water 1.0 times the weight of the egg white to obtain egg white liquid, adjust the pH value of the egg white liquid to 6 with dilute hydrochloric acid solution, and then use a plate and frame filter press Remove the sediment and solid impurities in the egg white liquid, and then send it to a homogenizer for homogenization for 20 minutes. The homogenized egg white liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com