Hierarchical porous supported nickel-based catalyst, preparation method and application

A nickel-based catalyst, supported technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as carbon deposition, deactivation, and easy sintering, and achieve long catalyst life and enhanced Effects of interaction, excellent carbon deposition and sintering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

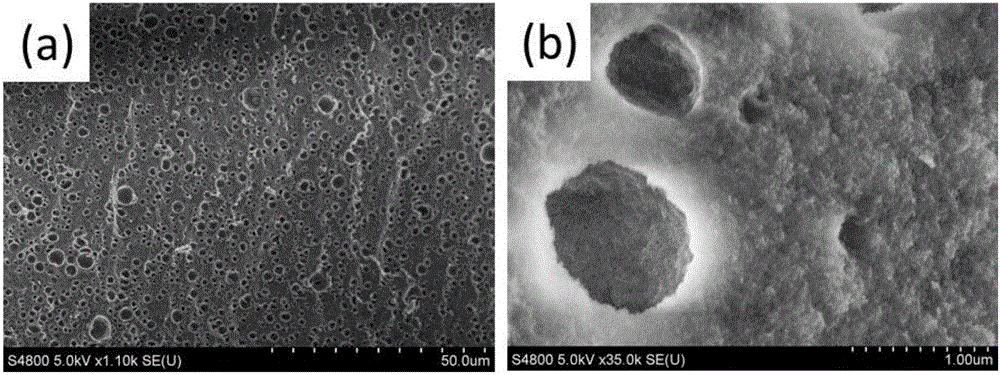

[0047] Preparation and Characterization of Catalyst Samples CAT-1~CAT-11 of Embodiment 1

[0048] Take a certain amount of nickel salt and dissolve it in 10ml of ethanol to make a solution, add 5g of hierarchical porous alumina, ultrasonic impregnation for a period of time, filter to remove the solvent and excess unabsorbed nickel salt. The aluminum oxide adsorbed with nickel ions was vacuum-dried at 80° C. for 8 hours, calcined in an air atmosphere, and finally reduced with hydrogen to obtain the hierarchically porous supported nickel-based catalyst.

[0049] The nickel content on the hierarchically porous supported nickel-based catalyst was determined by ICP. The particle size range of nickel particles on the hierarchical porous supported nickel-based catalyst was observed by transmission scanning electron microscope.

[0050] See Table 1 for the relationship between the sample number and specific experimental parameters, the mass percentage of nickel element in the hierarc...

Embodiment 2

[0054] Embodiment 2 Catalyst reaction evaluation

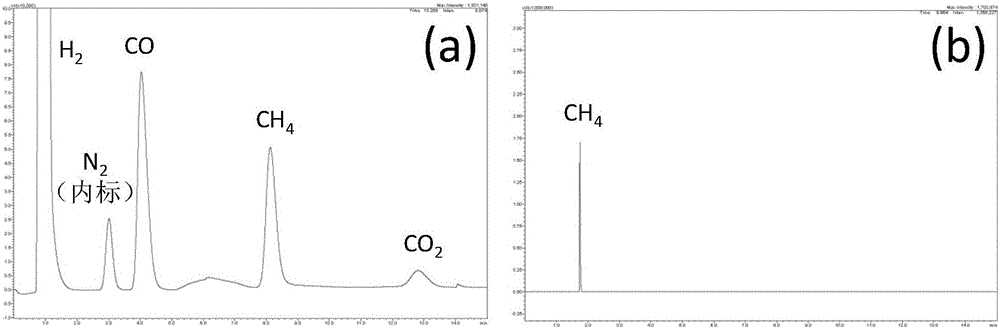

[0055] Take 0.2g of the catalyst sample CAT-1 and place it in a fixed-bed reactor with an inner diameter of 1cm. After hydrogen reduction is performed online, the temperature is adjusted to the reaction temperature. switch gas to CO 2 and CH 4 Mixed gas, N 2 is the internal standard. After the reaction, the gas is cooled and enters the gas chromatograph to detect the concentration of each substance, and calculate the CO 2 and CH 4 conversion rate.

[0056] Reaction conditions and CO 2 and CH 4 The relationship between the conversion rate is shown in Table 2.

[0057] When the reaction condition is A, the chromatographic detection result of the reaction tail gas is as follows figure 2 shown. It can be seen from the figure that the multi-level porous supported nickel-based catalyst provided by the present application has good selectivity, and the product is basically the main components of synthesis gas: hydrogen and ...

Embodiment 3

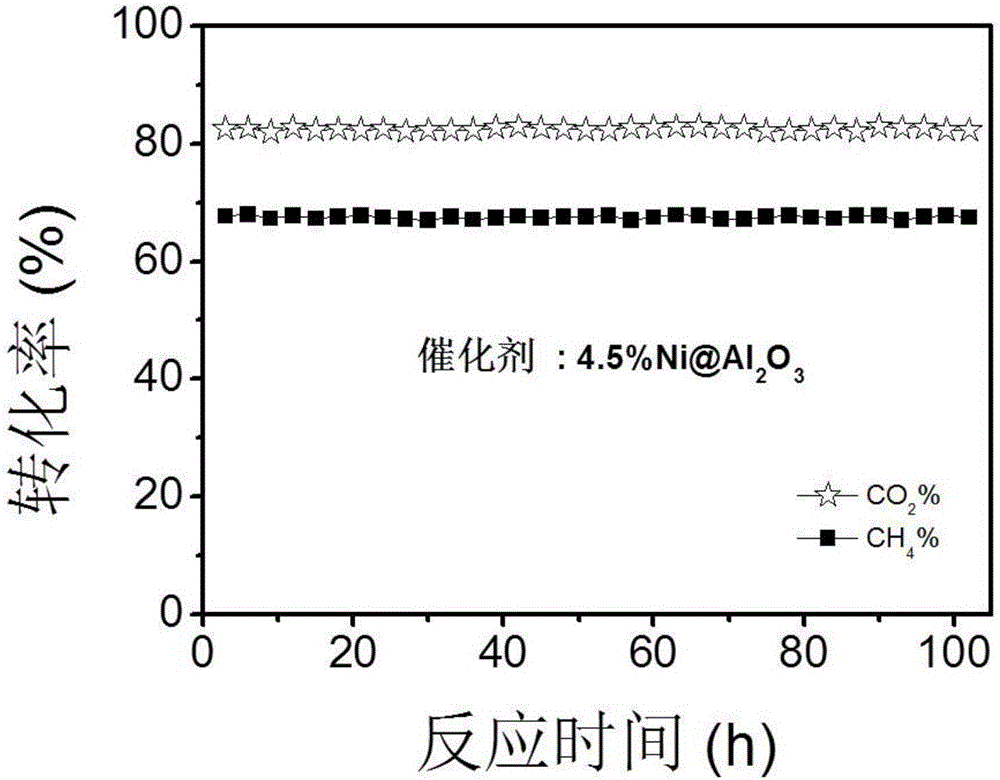

[0066] Embodiment 3 Catalyst stability evaluation

[0067] Get 0.2g catalyst sample CAT-1 and place in the fixed-bed reactor of internal diameter 1cm, under the reaction condition A of embodiment 2, carry out catalyst stability evaluation, the result is as follows image 3 shown. Depend on image 3 It can be seen that the hierarchical porous supported nickel-based catalyst provided by the present application has excellent stability under normal pressure and 800°C reaction conditions, and the conversion rates of carbon dioxide and methane remain basically unchanged within 100 hours of reaction time.

[0068] The transmission electron microscope photos of the catalyst sample CAT-1 before and after the reaction are as follows: Figure 4 shown. Figure 4 (a) is a transmission electron micrograph of the sample CAT-1 before the reaction; Figure 4(b) is a transmission electron micrograph of sample CAT-1 after reacting at 800° C. for 102 hours. It can be seen from the figure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com