Chlorella and application thereof

A technology of chlorella and microalgae oil, which is applied in the direction of single-cell algae, biochemical equipment and methods, microorganisms, etc., can solve the problem of high production cost of microalgae oil, and achieve the effect of reducing the cost of cultivation and high immobilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

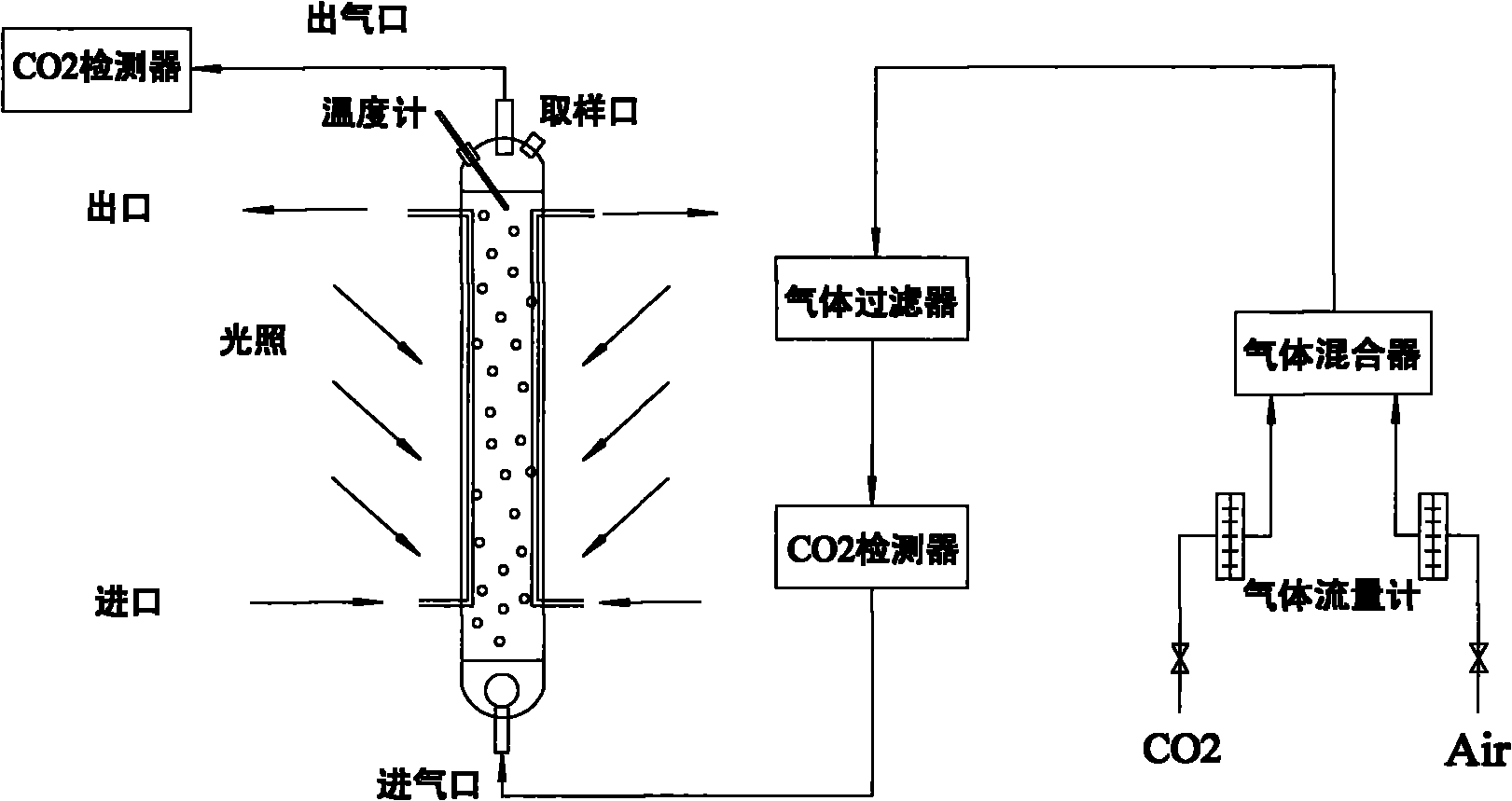

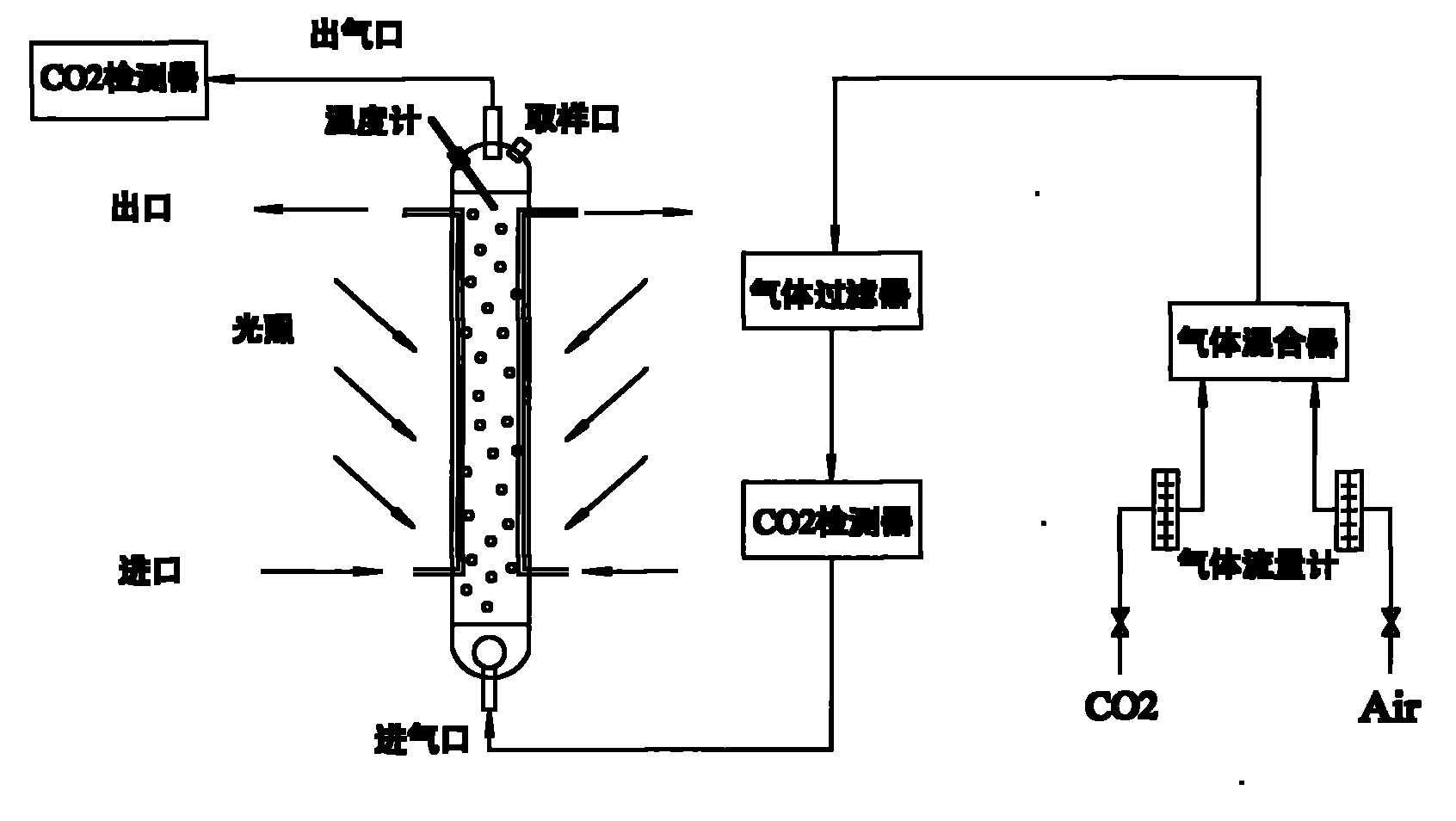

Embodiment 1

[0027] Use 5 L of modified f / 2 medium in a self-made photobioreactor, and insert the cell density at 5×10 7 Individual / ml algae liquid 500mL. Into 0.25vvm air, CO 2 The content is 0.03% (v / v), after 15 days of cultivation, the biomass reaches 1.1g / L, CO 2 Absorption rate 6%. The oil content was 21% when cultured to 15 days.

Embodiment 2

[0029] Use 5L of modified f / 2 medium in a self-made photobioreactor, the initial pH is 7.2, the temperature is 27°C±0.5°C, the light intensity is 5000lux, and 0.25vvm air and CO are introduced 2 Mixed gas, where CO 2 The content is 5% (v / v), and the density of inserted cells is about 5×10 7 Individual / mL algae liquid 500mL. After 15 days of cultivation, the biomass reached 2.23g / L, CO 2 The absorption rate is 51%. The oil content was 31% when cultured to 15 days.

Embodiment 3

[0031] Use 5L of modified f / 2 medium in a self-made photobioreactor, the initial pH is 7.2, the temperature is 27°C±0.5°C, the light intensity is 5000lux, and 0.25vvm air and CO are introduced 2 Mixed gas, where CO 2 The content is 10% (v / v), and the density of inserted cells is about 5×10 7 Individual / mL algae liquid 500mL. After 15 days of cultivation, the biomass reached 1.91g / L, CO 2 The absorption rate is 26%. The oil content was 22% when cultured to 15 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com