Production unit for microalgae industrialization and method for producing microalgae

A production device and a technology for microalgae, which are applied in the field of microalgae industrialized production devices, can solve the problems of high production cost of microalgae cultivation, high cost of construction and maintenance, and difficulty in popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

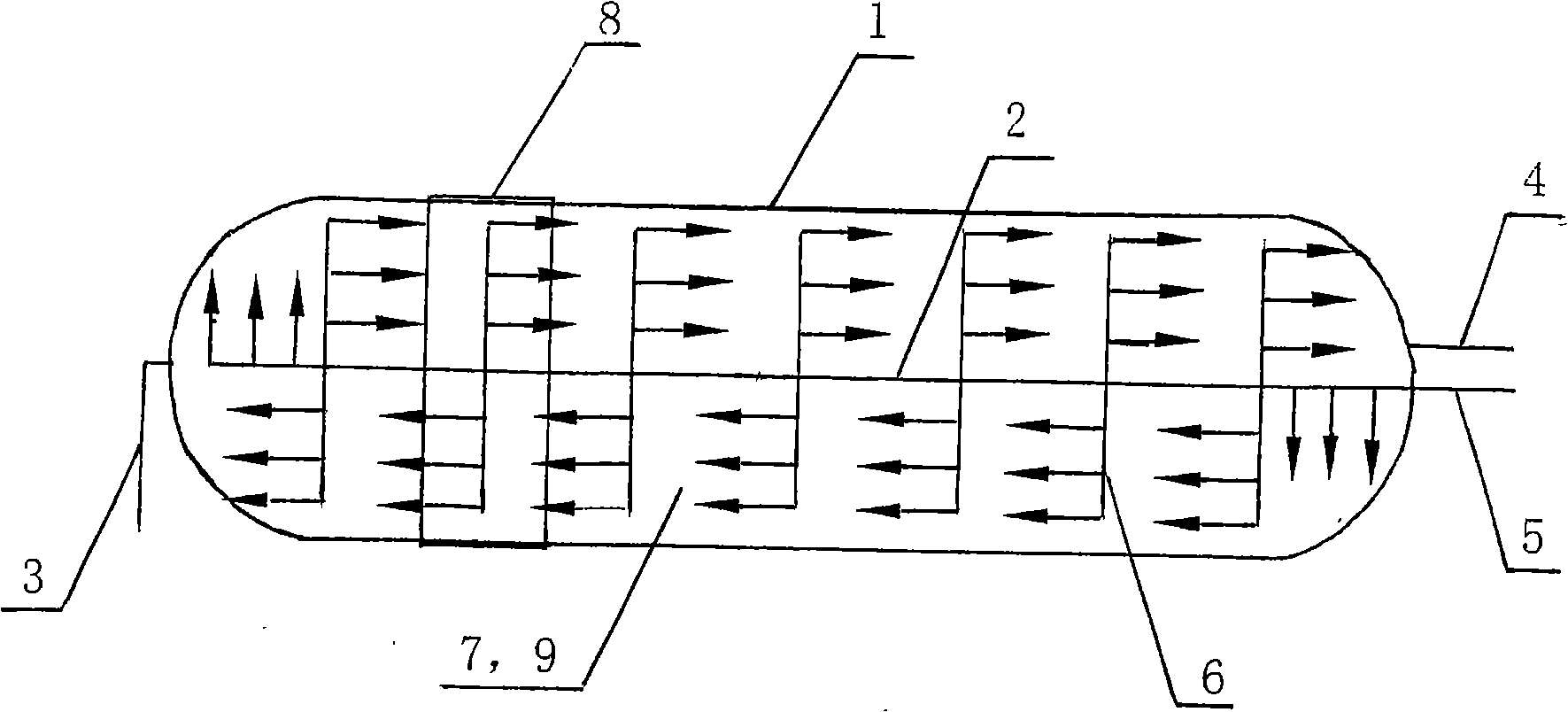

[0018] Embodiment 1 (single reactor)

[0019]The single air-push photobioreactor for cultivating microalgae is an annular shallow pool 1 built with bricks and concrete, and a partition wall 2 with open ends is built with bricks in the pool. The width of the pool is 3 meters, and the length is 60 meters. meters and a depth of 40 cm. The bottom of the air-push photobioreactor is equipped with a liquid discharge pipe 3, and the upper part is equipped with a liquid replenishment pipe 4. Intake pipe 5 is fixed on the partition wall in the middle part of the air-push photobioreactor, and 120 L-shaped branch pipes 6 are connected on the air inlet pipe. The wall is vertical; a row of small holes with a diameter of 1 mm is evenly opened on the side wall of the horizontal tube, the density of the holes is 3 per cm, and the airflow direction is horizontally forward, thus, the air-push photobiological reaction The water body in the container is driven by countless tiny airflows in the s...

Embodiment 2

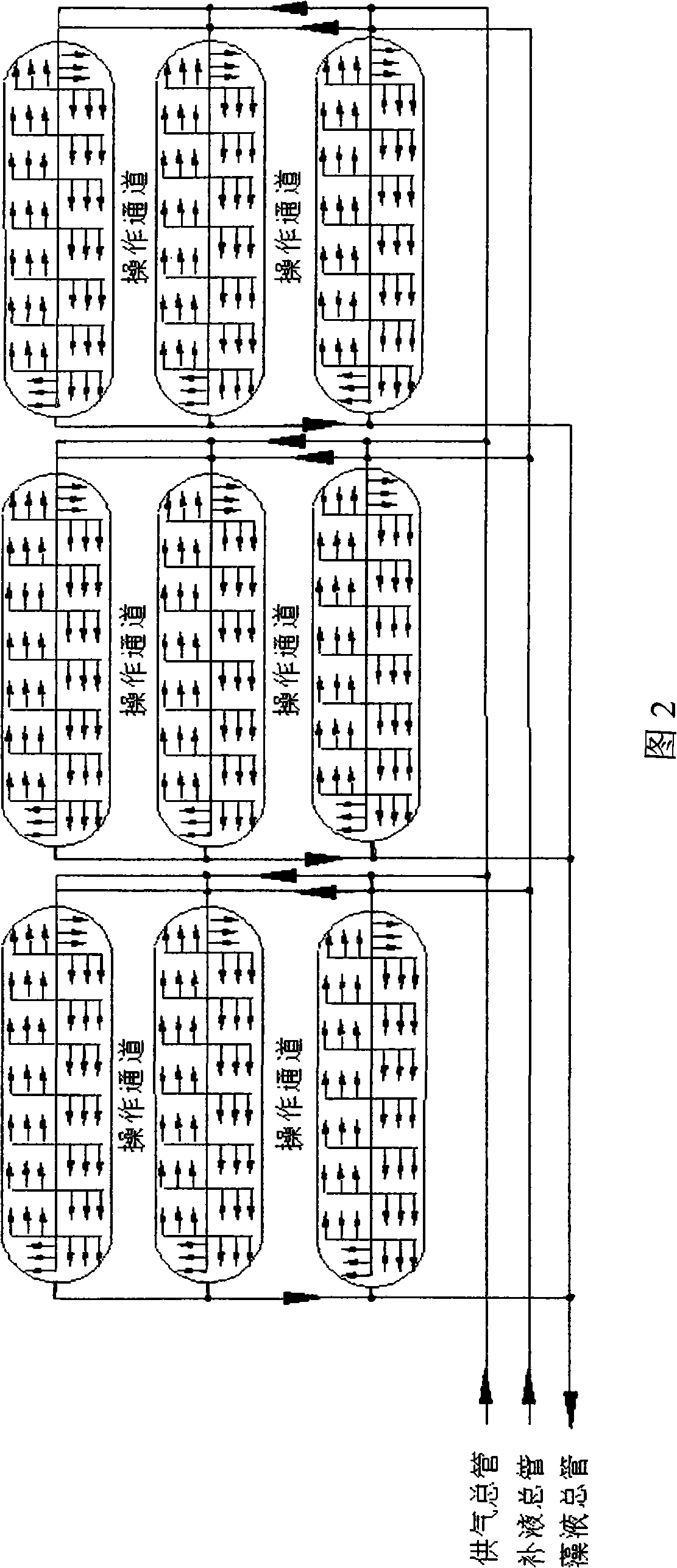

[0023] Embodiment 2 (multiple reactors)

[0024] In industrialized large-scale production of microalgae, it is necessary to use multiple air-push photobioreactors for parallel production. The layout of the reactors and pipelines is shown in Figure 2. In each row, the reactors are closely arranged, leaving only the distance between two adjacent reactors for the pipeline. An operation channel of 0.5 meters should be reserved between two adjacent rows of reactors to facilitate operations such as film laying, sampling, opening skylights for ventilation, cleaning, and switching valves.

[0025] The east-west layout of the gas supply main pipe and the liquid replenishment main pipe passes through each row of reactors and divides into a north-south branch pipe, which enters the reactor at the end of each reactor to supply gas and liquid for the reactor. When collecting the algae liquid, the algae liquid is first discharged into a north-south branch pipe next to the reactor, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com