Lignite drum smoke pre-drying power generation integrated system and process

An integrated system, drum dryer technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problem of difficult to meet the drying output, and achieve the effect of reducing emissions and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

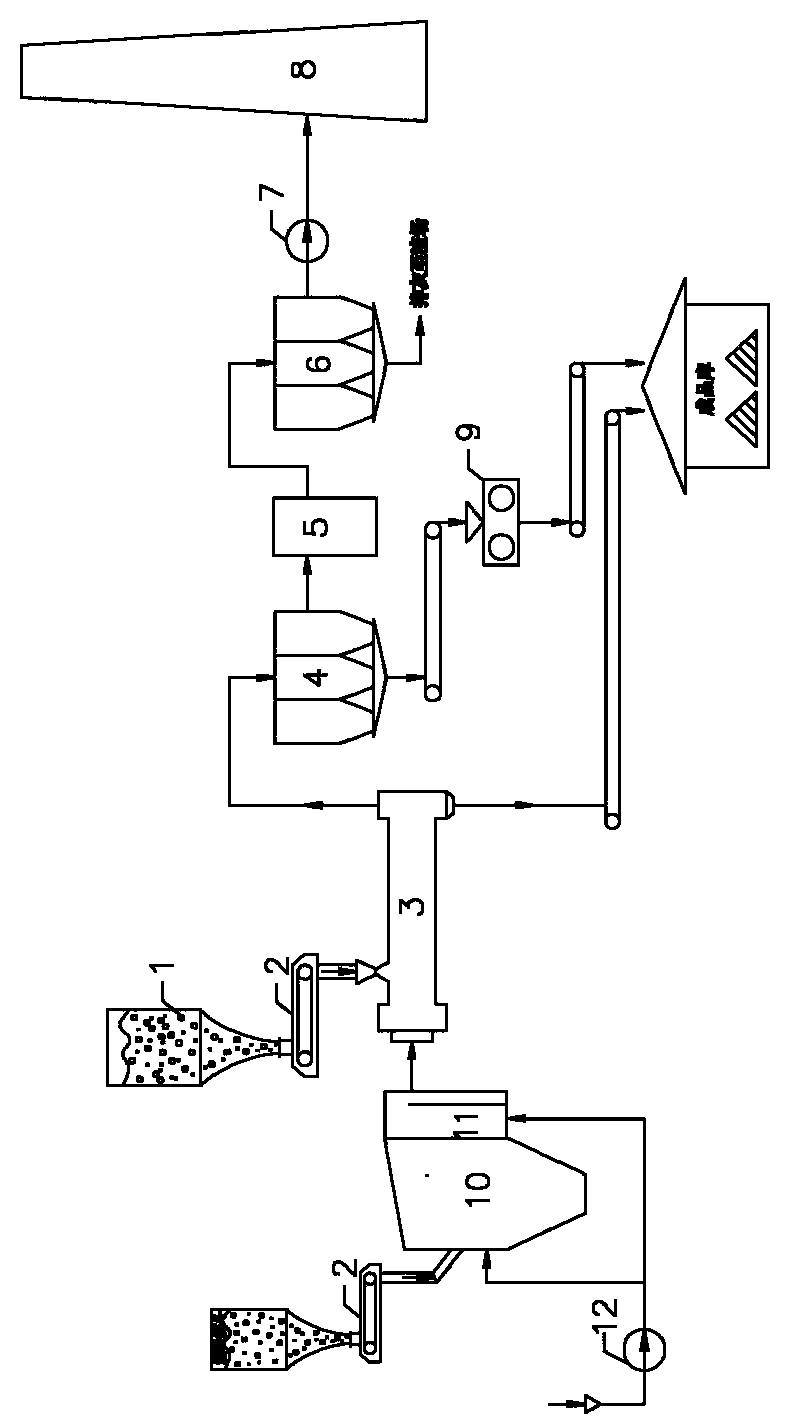

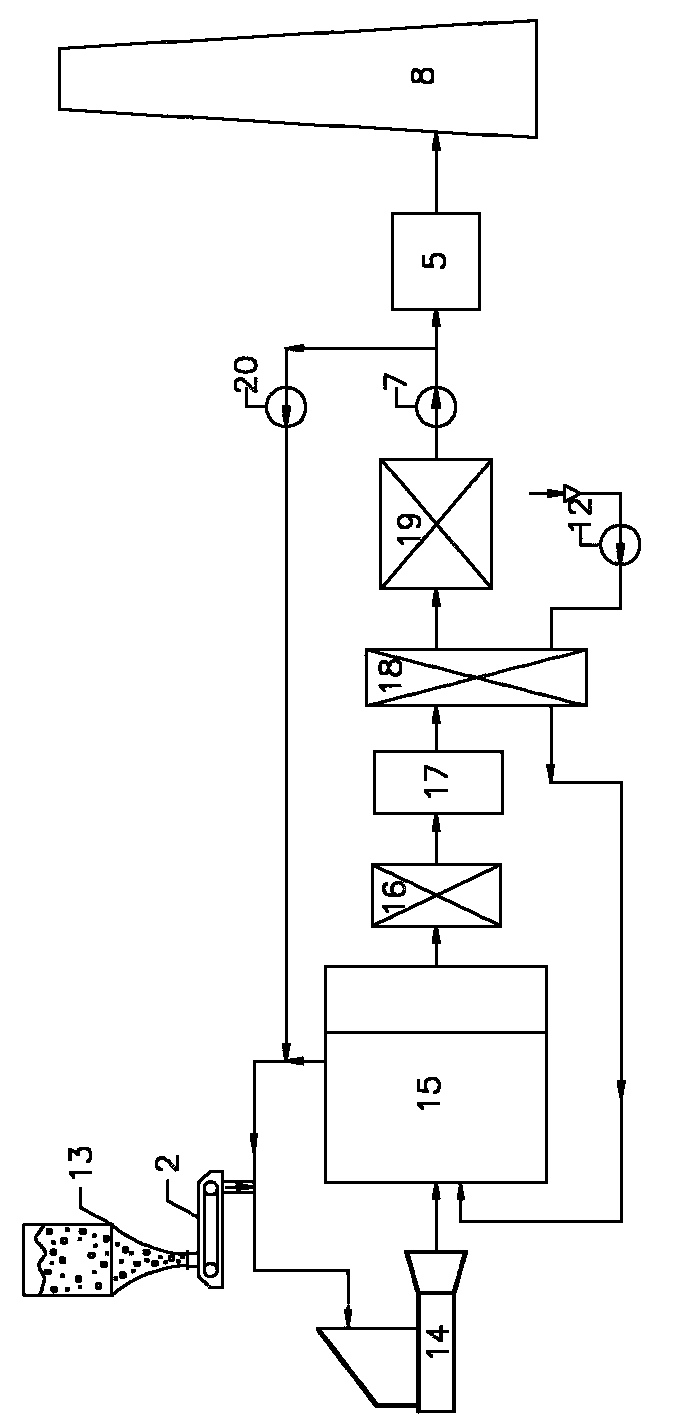

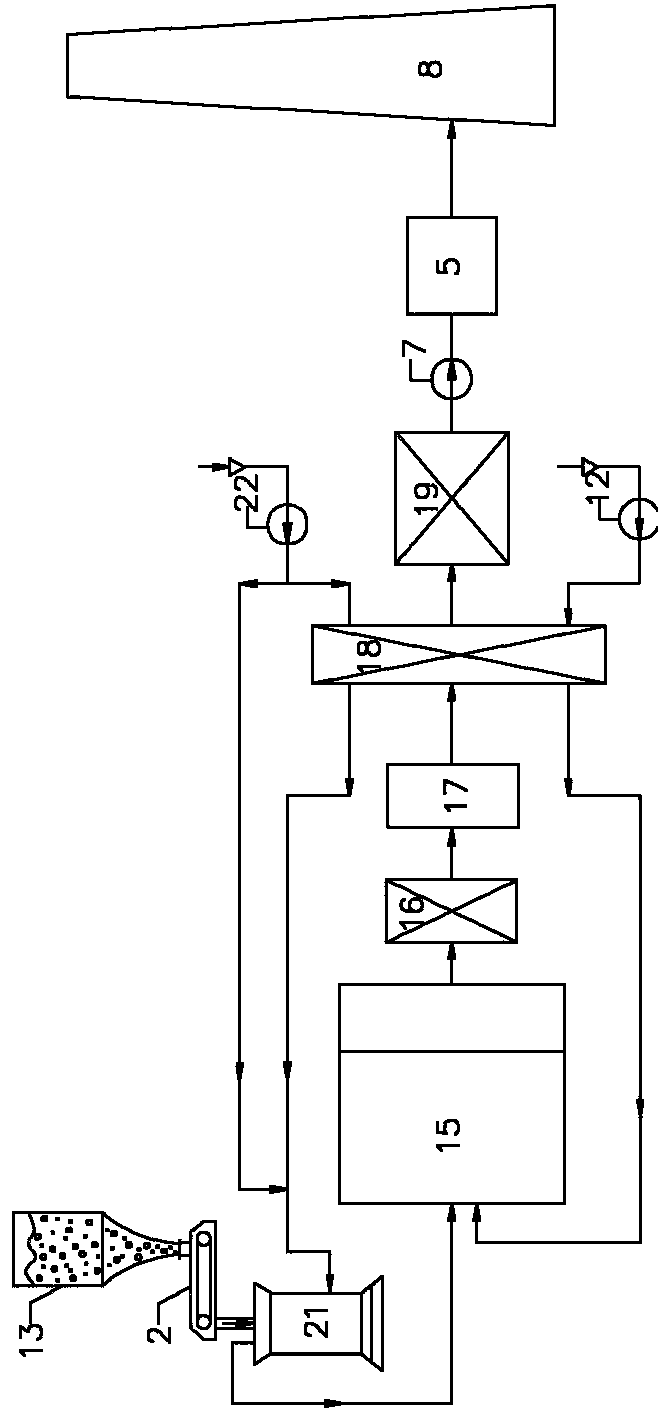

[0022] The invention proposes a system and a process method for integrating a lignite pre-drying system with a boiler combustion system. For the system and process of integrating the lignite pre-drying system with the medium-speed coal pulverization system and the boiler combustion system, please refer to Figure 4 As shown, the system has two parts: the boiler combustion system and the lignite pre-drying system. The lignite pre-drying system is connected in parallel to the boiler combustion system. Specifically, the boiler combustion system includes boiler coal hoppers 13 and boiler coal feeders 24 connected in sequence. , medium-speed coal mill 21, boiler 15, economizer 16, denitration device 17, air preheater 18, dust collector 19, induced draft fan 7, desulfurization device 5 and chimney 8, primary fan 22 and medium-speed coal mill 21 are connected, and the air heated in the air preheater 18 is sent to the medium-speed coal mill 21 at the same time. However, the lignite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com