Preparation method of iron-carbon micro-electrolysis ceramsite filler for water treatment

An iron-carbon micro-electrolysis and water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of occupying land resources, increasing production costs, and environmental hazards, etc. Achieve the effects of low preparation cost, resource saving and great social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

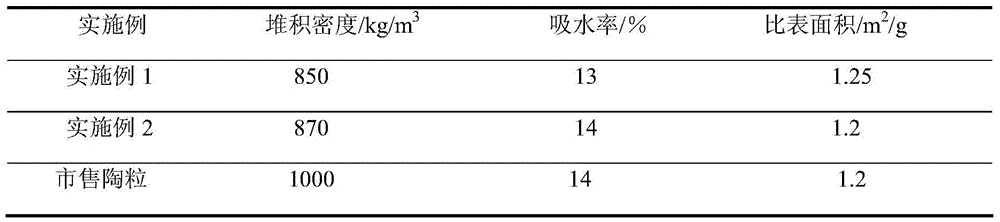

Embodiment 1

[0021] Embodiment 1, concrete steps are:

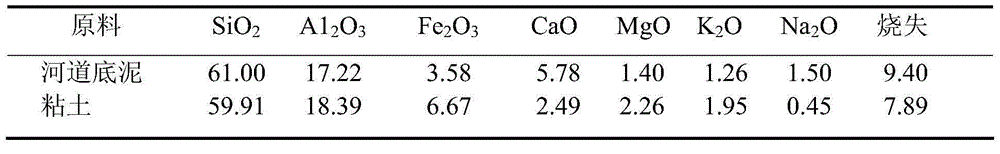

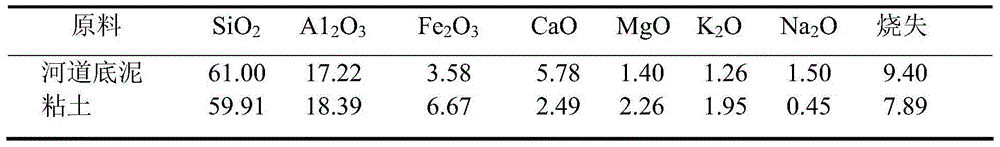

[0022] Step 1) Prepare the mixture: mix scrap iron scraps, waste circuit board powder, river bottom mud powder and clay in the loess cliff section of Xiaofu River, Zibo City, Shandong Province, with a mass ratio of 15:60:10:15 to form a mixture; Among them, scrap iron scraps contain 98% iron, which is ground through a 100-mesh sieve; waste circuit board powder is ground through a 100-mesh sieve after being crushed from waste circuit boards, and then successively undergoes magnetic separation to remove iron and electric separation to remove copper. Waste circuit board powder contains 81% of epoxy resin, 13% of glass fiber and 2.15% of metal copper, and the others are a small amount of iron, aluminum, tin, gold, silver, platinum, etc.; the river bottom mud powder is from Zibo City, Shandong Province The bottom mud of the Huangtuya section of the river is ground and passed through a 120-mesh sieve. The mass percentage of clay in the rive...

Embodiment 2

[0027] Embodiment 2, concrete steps are:

[0028] Step 1) Prepare the mixture: mix scrap iron scraps, waste circuit board powder, river bottom mud powder and clay in the loess cliff section of Xiaofu River, Zibo City, Shandong Province, with a mass ratio of 15:55:15:15 to form a mixture; Others are with embodiment 1.

[0029] Step 2) Add the mixture into the disc granulator, and add 25% binder diluent to granulate the mixture to obtain Spherical particles; the preparation of the binder diluent is as follows: first heat 0.5wt% polyvinyl alcohol until the polyvinyl alcohol melts, and then add 80°C hot water to dilute 6 times to prepare the binder diluent, which is ready-to-use .

[0030] Step 3) The spherical particles are first dried in a drying oven at 100°C, and then calcined in an oxygen-free atmosphere in a box-type atmosphere furnace protected by nitrogen. The calcination system is 0°C to 600°C, and the heating rate is controlled at 10°C / min , when the temperature reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com